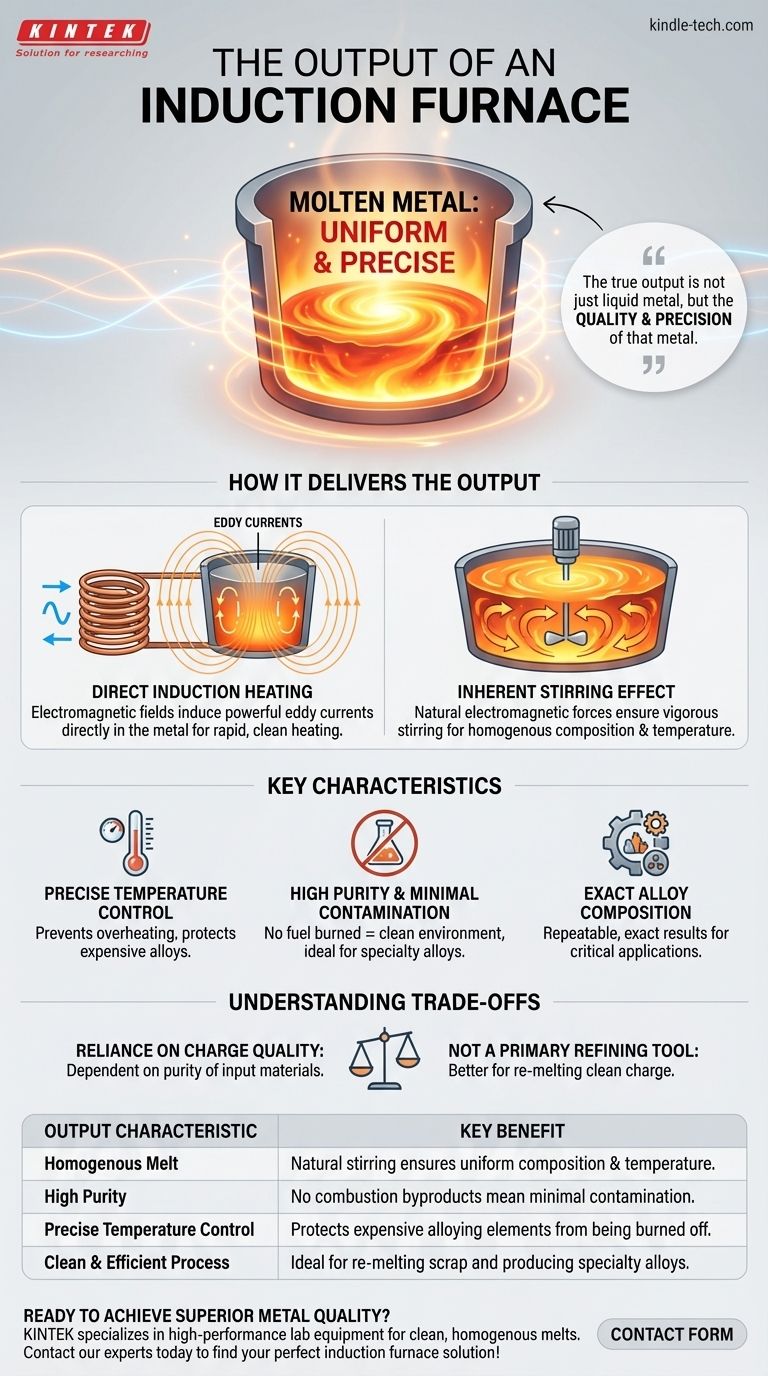

The primary output of an induction furnace is molten metal of a highly uniform temperature and precisely controlled composition. Unlike traditional furnaces that burn fuel, an induction furnace uses electromagnetic fields to heat the metal directly, resulting in a cleaner, more homogenous, and efficient melting process ideal for producing high-quality metals and alloys.

The true output of an induction furnace is not merely liquid metal, but rather the quality and precision of that metal. Its core function is to produce a clean, thoroughly mixed, and thermally uniform melt, making it indispensable for applications demanding exact metallurgical properties.

How an Induction Furnace Delivers Its Output

To understand the output, we must first understand the mechanism. The furnace's design directly contributes to the unique characteristics of the molten metal it produces.

The Principle of Direct Induction Heating

An induction furnace operates without any external flame or heating element touching the metal. A powerful alternating current flows through a copper coil, which generates a fluctuating magnetic field inside the furnace.

This magnetic field penetrates the metal charge placed within a crucible, inducing powerful electrical currents—known as eddy currents—directly within the metal itself. The metal's natural resistance to these currents generates intense heat, causing it to melt rapidly from the inside out.

The Inherent Stirring Effect

The same electromagnetic forces that generate heat also create a vigorous stirring action within the molten bath. This is a critical, built-in feature of the process.

This natural circulation ensures that all alloying elements are distributed evenly throughout the melt. The result is a homogenous liquid metal with a consistent chemical composition and temperature from top to bottom.

Key Characteristics of the Output

The method of heating and mixing defines the quality of the final product. The output of an induction furnace is prized for several specific attributes.

Precise Temperature Control

Because the heat is generated by electrical power that can be regulated with extreme precision, operators have fine-tuned control over the melt temperature. This prevents overheating, which can burn off valuable and expensive alloying elements.

High Purity and Minimal Contamination

Induction furnaces are exceptionally clean. Since no fuel is burned, there are no byproducts of combustion (like carbon or sulfur) to contaminate the metal. This makes the process ideal for producing high-purity metals and specialty alloys where even trace impurities are unacceptable.

Exact Alloy Composition

The combination of precise temperature control, a clean melting environment, and the natural stirring action allows foundries to produce alloys with an exact, repeatable composition. This is essential for creating materials with specific mechanical properties for industries like aerospace, automotive, and medical manufacturing.

Understanding the Trade-offs

While highly effective, the technology is not a universal solution. Its strengths define its ideal applications and limitations.

Reliance on Charge Quality

An induction furnace is primarily a melting device, not a refining one. It does not effectively remove existing impurities from the input metals. Therefore, the purity of the output is almost entirely dependent on the quality of the scrap metal or raw materials (the "charge") used.

Not a Primary Refining Tool

Processes that require significant refining—such as removing large amounts of carbon from iron ore to make steel—are better suited to other furnace types, like a Basic Oxygen Furnace or Electric Arc Furnace. Induction furnaces excel at re-melting and alloying clean charge materials.

Making the Right Choice for Your Goal

The decision to use an induction furnace hinges on the desired quality and type of your final product.

- If your primary focus is producing high-value, specialty alloys: The furnace's precision, cleanliness, and homogenous mixing are essential for meeting strict metallurgical specifications.

- If your primary focus is clean and efficient re-melting: The process is ideal for foundries that need to melt down scrap or ingots into new products with minimal metal loss and environmental impact.

- If your primary focus is preserving expensive alloying elements: The precise temperature control ensures these valuable metals are not burned off, providing significant cost savings and consistent quality.

Ultimately, an induction furnace delivers a level of control and purity that conventional melting technologies cannot easily match.

Summary Table:

| Output Characteristic | Key Benefit |

|---|---|

| Homogenous Melt | Natural stirring ensures uniform composition and temperature. |

| High Purity | No combustion byproducts mean minimal contamination. |

| Precise Temperature Control | Protects expensive alloying elements from being burned off. |

| Clean & Efficient Process | Ideal for re-melting scrap and producing specialty alloys. |

Ready to achieve superior metal quality and precise alloy control in your lab or foundry? KINTEK specializes in high-performance lab equipment, including induction furnaces designed for reliability and precision. Our solutions help you produce clean, homogenous melts with exact compositions, ensuring consistent results for your most demanding applications. Contact our experts today to find the perfect induction furnace for your specific needs!

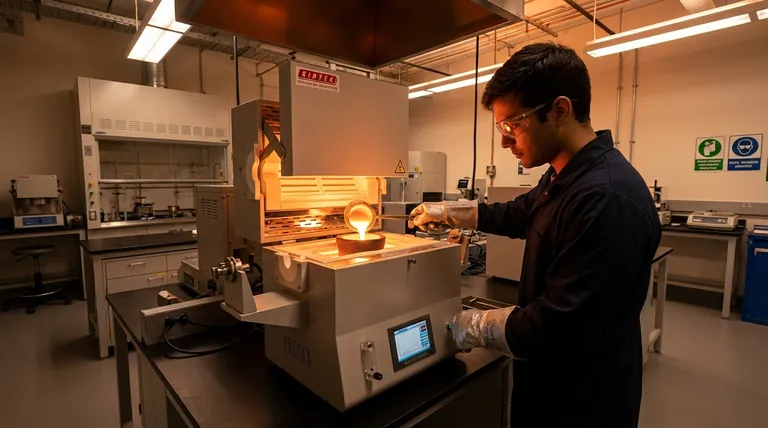

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.