The core principle behind a hydraulic press is Pascal's Law, which allows for immense force multiplication using an incompressible fluid. This law states that any pressure applied to a fluid inside a closed system will be transmitted equally throughout the entire fluid. A hydraulic press exploits this by using a small initial force on a small area to generate a much larger output force over a larger area.

The fundamental insight is that a hydraulic press does not create energy, but rather multiplies force. It achieves this by converting a small force applied over a small piston into a system-wide pressure, which then acts on a larger piston to produce a proportionally greater output force.

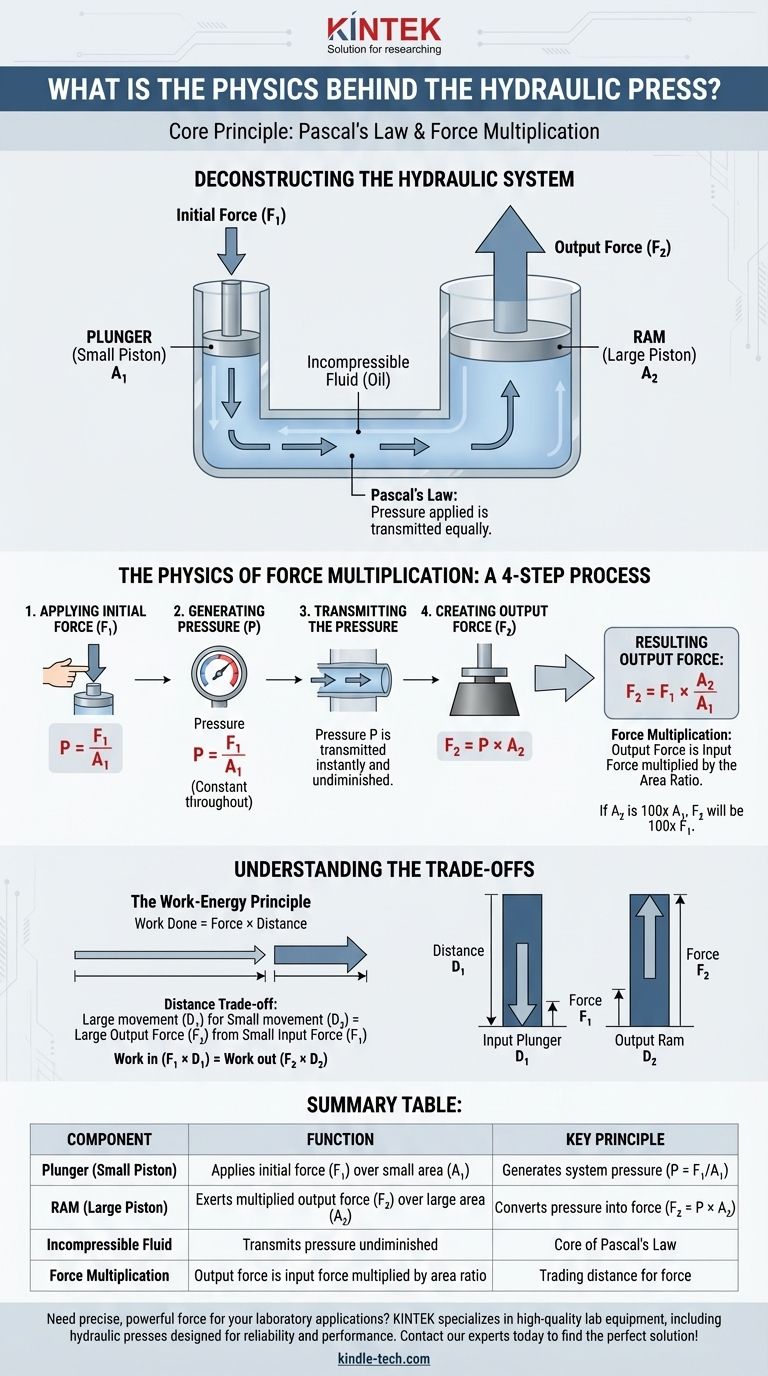

Deconstructing the Hydraulic System

To understand the physics, we must first look at the essential components that make up any hydraulic press. These parts work together in a closed system to transfer and multiply force.

The Two Pistons: Plunger and Ram

Nearly every hydraulic press has two pistons of different sizes. The smaller piston, often called the plunger, is where the initial, smaller force is applied. The larger piston, known as the ram, is what exerts the massive compressive force to do the work.

The Incompressible Fluid

The pistons are housed in cylinders connected by a channel filled with an incompressible fluid, typically a specialized oil. "Incompressible" is the key property—it means the fluid's volume does not change under pressure. This ensures that when you push the fluid on one end, it immediately transmits that force to the other end without being "squished."

The Physics of Force Multiplication

The true genius of the hydraulic press lies in how it uses the relationship between force, pressure, and area. The process is a clear, four-step application of Pascal's Law.

Step 1: Applying the Initial Force (F₁)

The process begins when a relatively small force (F₁) is applied to the small input piston, the plunger. This piston has a small surface area (A₁).

Step 2: Generating Pressure (P)

This initial force generates pressure within the hydraulic fluid. The amount of pressure is defined by the formula Pressure = Force / Area. So, the pressure (P) in the system is calculated as P = F₁ / A₁.

Step 3: Transmitting the Pressure

Here is where Pascal's Law is critical. The law guarantees that the pressure (P) you just created is transmitted instantly and undiminished to every part of the enclosed fluid. The pressure acting on the large ram is exactly the same as the pressure under the small plunger.

Step 4: Creating the Output Force (F₂)

This constant pressure (P) now pushes against the large output piston, the ram, which has a much larger surface area (A₂). The resulting output force (F₂) is calculated by rearranging the pressure formula: Force = Pressure × Area.

Therefore, the output force is F₂ = P × A₂.

Because we know P = F₁ / A₁, we can substitute it into the second equation to see the direct relationship: F₂ = (F₁ / A₁) × A₂. This can be simplified to show that the output force is the input force multiplied by the ratio of the areas: F₂ = F₁ × (A₂ / A₁).

If the ram's area (A₂) is 100 times larger than the plunger's area (A₁), the output force (F₂) will be 100 times greater than the input force (F₁).

Understanding the Trade-offs

This force multiplication does not violate the laws of physics and is not a source of free energy. There is a fundamental trade-off dictated by the conservation of energy.

The Work-Energy Principle

In an ideal system, the work done on the input piston must equal the work done by the output piston. Work is calculated as Work = Force × Distance.

The Distance Trade-off

Because the output force (F₂) is much larger than the input force (F₁), the distance the output ram moves (D₂) must be proportionally smaller than the distance the input plunger travels (D₁).

To lift the massive ram by just one inch, you may need to push the small plunger down by 100 inches. You are trading a long movement with low force for a short movement with high force.

Making the Right Choice for Your Goal

Understanding this principle allows you to apply it to different objectives, whether in design, operation, or simple comprehension.

- If your primary focus is design: Concentrate on the ratio of the piston areas (A₂/A₁), as this ratio directly determines your system's force multiplication factor.

- If your primary focus is operation: Recognize that while the generated force is immense, the ram's movement will be slow and deliberate. This force-for-distance trade-off is a core safety and operational characteristic.

- If your primary focus is comprehension: The key takeaway is that pressure remains constant in a closed fluid, allowing a small force on a small area to become a large force on a large area.

By mastering this principle, you can see how simple fluid mechanics enables some of the most powerful machinery in the modern world.

Summary Table:

| Component | Function | Key Principle |

|---|---|---|

| Plunger (Small Piston) | Applies initial force (F₁) over a small area (A₁) | Generates system pressure (P = F₁/A₁) |

| Ram (Large Piston) | Exerts multiplied output force (F₂) over a large area (A₂) | Converts pressure into force (F₂ = P × A₂) |

| Incompressible Fluid | Transmits pressure undiminished throughout the system | Core of Pascal's Law |

| Force Multiplication | Output force is input force multiplied by area ratio (F₂ = F₁ × (A₂/A₁)) | Achieved by trading distance for force |

Need precise, powerful force for your laboratory applications? KINTEK specializes in high-quality lab equipment, including hydraulic presses designed for reliability and exacting performance. Whether you're compressing samples, molding materials, or require custom force application, our expertise ensures you get the right tool for your needs. Contact our experts today to find the perfect hydraulic press solution for your lab!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does temperature control in vacuum hot press furnaces affect aluminum matrix composites? Optimize Bonding & Strength

- What are the technical advantages of vacuum hot pressing? Optimize SiCp/6061 Composite Performance

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- How does the pressure loading system of a vacuum hot press furnace regulate CoCrCuFeNi alloy microstructure?

- Primary Function of Vacuum System in Hot Press Furnaces? Optimize Co-50Cr Alloy Sintering & Purity