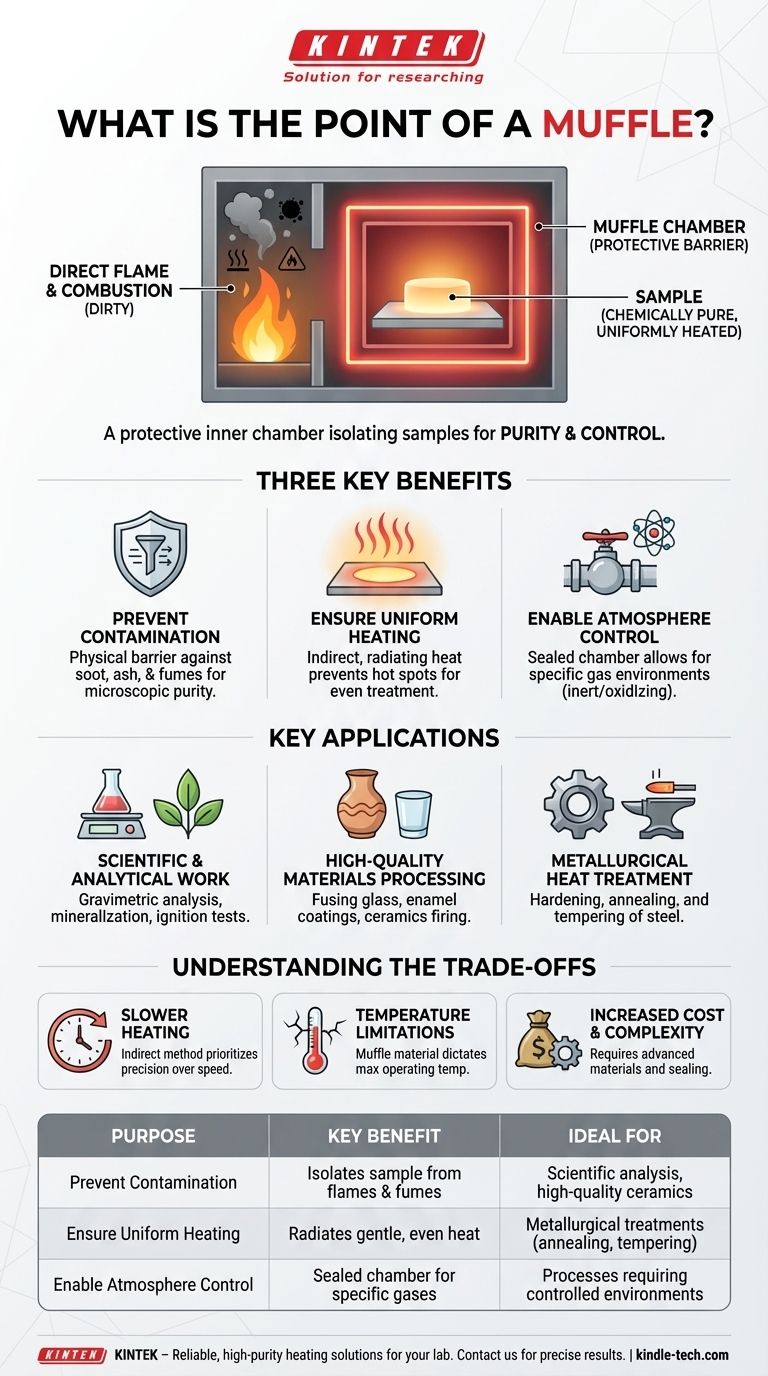

The fundamental purpose of a muffle is to act as a protective inner chamber within a furnace. This chamber isolates the material being heated from the direct flame, fuel, and chemical byproducts of combustion, such as ash or soot. This ensures the sample remains chemically pure and is heated uniformly and gently.

At its core, a high-temperature process is often "dirty" and chaotic. A muffle transforms a furnace into a precise instrument by creating a cleanroom at high temperatures, isolating the workpiece to guarantee purity and controlled heating—two factors that are non-negotiable for sensitive scientific analysis and high-quality material treatments.

The Core Principle: Isolation for Purity and Control

The value of a muffle furnace comes from its ability to separate the heat source from the object being heated. This separation provides two primary advantages: purity and control.

Preventing Contamination

Historically, furnaces burned fuel that produced contaminating byproducts like soot, ash, and fumes. A muffle creates a physical barrier, ensuring these contaminants never touch the workpiece.

This is critical in applications where even microscopic impurities can ruin the outcome, such as in a laboratory setting or when creating delicate ceramics.

Ensuring Uniform Heating

Direct exposure to a flame or heating element can create intense hot spots on a material, leading to uneven treatment, warping, or damage.

The muffle heats up and then radiates thermal energy evenly from all sides onto the sample inside. This indirect heating is far more gentle and uniform, which is essential for processes like annealing steel or firing delicate castings.

Enabling Atmosphere Control

Modern muffle systems allow for precise control over the gaseous atmosphere surrounding the sample.

The sealed muffle can be filled with a specific gas—such as an inert gas to prevent oxidation or an oxidizing gas to encourage it. This level of control is impossible in a furnace where the sample is exposed to the open combustion environment.

Key Applications Driven by the Muffle

The ability to create a clean, controlled, high-temperature environment makes muffle furnaces indispensable in several fields.

Scientific and Analytical Work

In laboratories, a muffle is essential for processes where sample purity is the main objective.

This includes gravimetric analysis, where a sample is weighed after being burned, mineralization of plant samples, or ignition tests for materials like coal. Any contamination from the furnace itself would invalidate the results.

High-Quality Materials Processing

Many industrial processes depend on a pristine surface finish that would be ruined by direct flame.

This is true for fusing glass, creating enamel coatings, and firing ceramics. The muffle guarantees that the final product is clean and has the desired aesthetic and structural properties.

Metallurgical Heat Treatment

Processes like hardening, annealing, and tempering of steel require incredibly precise temperature control to achieve specific crystalline structures.

A muffle provides the uniform, repeatable heating and controlled atmosphere necessary to reliably produce metals with the desired hardness, ductility, and strength.

Understanding the Trade-offs

While invaluable, the muffle design is not without its inherent limitations. Understanding these trade-offs is key to appreciating its specific role.

Slower Heating Rates

Because the heat must first transfer to the muffle and then radiate to the sample, the overall heating process is slower than with a direct-fire furnace. This indirect method prioritizes precision over raw speed.

Temperature Limitations

The furnace's maximum operating temperature is often limited by the material of the muffle itself. The inner chamber is exposed to extreme thermal stress and must be made of a highly resilient ceramic or alloy, which can be a point of failure.

Increased Cost and Complexity

A furnace with a high-quality, sealed muffle is inherently more complex and costly to manufacture than a simple forge or open-element kiln. The design requires advanced materials and engineering to ensure durability and a proper seal.

When a Muffle is Essential

The decision to use a muffle furnace hinges on your process's sensitivity to contamination and its need for precision.

- If your primary focus is analytical purity: A muffle is non-negotiable for tasks like gravimetric analysis or elemental detection, as it prevents sample contamination.

- If your primary focus is surface quality: A muffle is critical for ceramics, enameling, or glasswork to protect the workpiece from soot and ensure a flawless finish.

- If your primary focus is precise material properties: A muffle provides the uniform heating and atmospheric control required for repeatable metallurgical treatments like annealing.

Ultimately, a muffle transforms a raw heat source into a precise and sterile high-temperature instrument.

Summary Table:

| Purpose | Key Benefit | Ideal For |

|---|---|---|

| Prevent Contamination | Isolates sample from flames & fumes | Scientific analysis, high-quality ceramics |

| Ensure Uniform Heating | Radiates gentle, even heat | Metallurgical treatments (annealing, tempering) |

| Enable Atmosphere Control | Sealed chamber for specific gases | Processes requiring controlled oxidation/inert environments |

Need a reliable, high-purity heating solution for your lab?

KINTEK specializes in premium lab equipment, including muffle furnaces designed to protect your samples and ensure precise, repeatable results. Whether you're in research, quality control, or materials development, our solutions deliver the contamination-free environment and uniform heating your work demands.

Contact KINTEK today to find the perfect muffle furnace for your application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the functions of vacuum filtration and laboratory ovens in PVC/GO processing? Optimize Composite Purity

- What type of insulation is used in a muffle furnace? Essential Materials for High-Temperature Performance

- How does a muffle furnace work? A Guide to Clean, High-Temperature Heating

- What is the primary application of a high-temperature muffle furnace in Li-LSX zeolite catalyst regeneration?

- What function do furnaces serve in Li6PS5Cl preparation? Master Sulfide Electrolyte Crystallization

- What role does a high-temperature box-type resistance furnace play in Alloy 718 homogenization? | KINTEK Solution

- Why is a high-temperature muffle furnace with atmosphere control required for LDH calcination? Master the Memory Effect

- What is the use of a furnace chamber? A Guide to Controlled High-Temperature Processing