The typical pressure for isostatic pressing varies significantly based on the method. For Cold Isostatic Pressing (CIP), the most common type, pressures range from 1,035 to 4,138 bar (15,000 to 60,000 psi). Other methods, such as Warm or Hot Isostatic Pressing, use different pressure and temperature combinations to achieve specific material properties.

The critical factor in isostatic pressing isn't a single universal pressure value, but rather the uniformity of the pressure applied. The specific pressure required is determined by the chosen method (Cold, Warm, or Hot) and the material being processed.

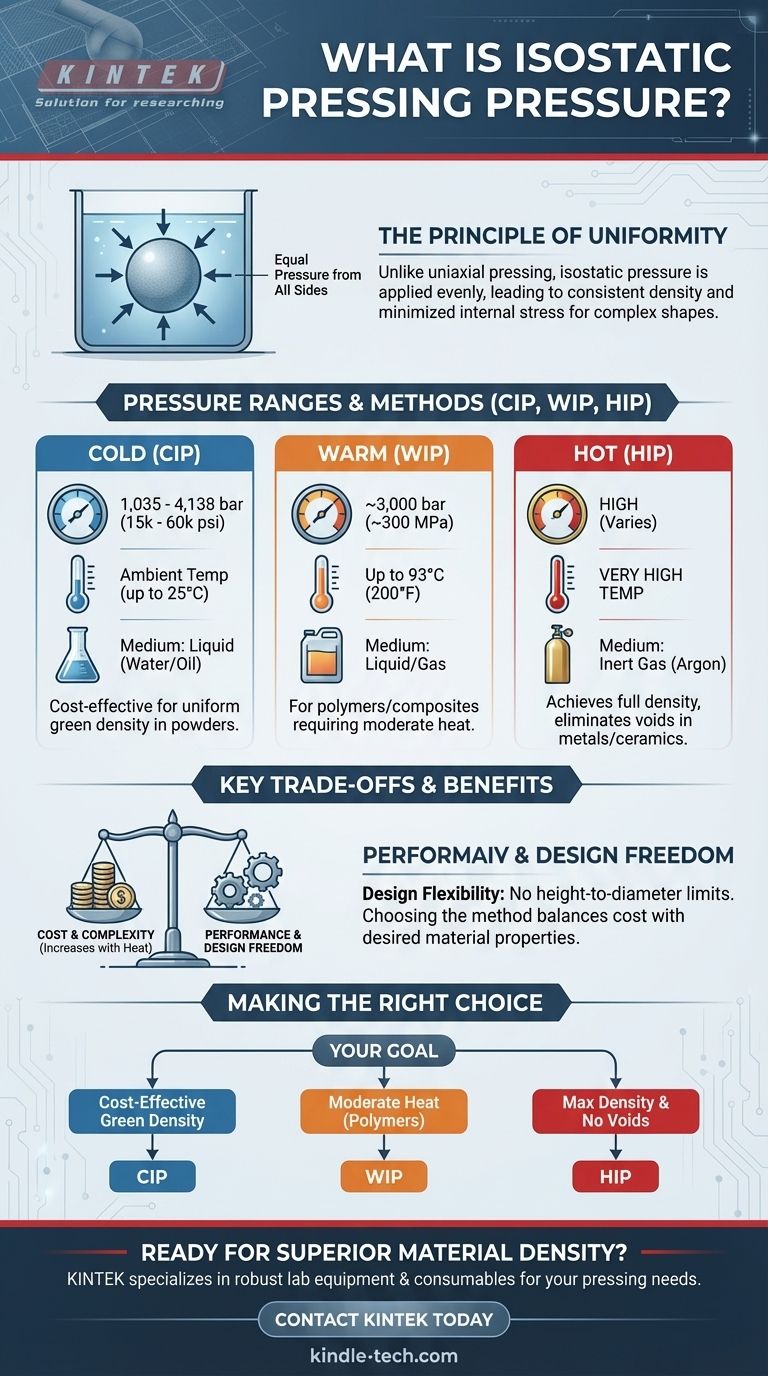

What "Isostatic" Pressure Truly Means

The term "isostatic" is the key to understanding this entire process. It defines how the force is applied, which directly impacts the quality and uniformity of the final product.

The Principle of Uniformity

Isostatic pressure is defined as pressure exerted equally from all directions. A simple analogy is an object submerged deep underwater; the water pressure is applied to every surface of the object simultaneously and with equal force.

This uniformity is achieved by using a fluid or gas as a pressure-transmitting medium.

The Impact on Material Density

In traditional uniaxial pressing, pressure comes from one or two directions. This can create density variations and internal stresses, especially in complex shapes.

Isostatic pressing eliminates this issue. Because the pressure is uniform, friction between the powder and the mold wall is minimal, leading to highly consistent compaction and density distribution throughout the part. This makes it ideal for brittle powders or parts with complex geometries.

Pressure Ranges for Different Pressing Methods

The combination of pressure and temperature is tailored to the specific application. The three main types of isostatic pressing operate under very different conditions.

Cold Isostatic Pressing (CIP)

This is the most widely used method. CIP is typically performed at ambient temperature, though the process itself can cause a minor temperature increase of up to 25°C.

It operates at pressures between 1,035 and 4,138 bar (15,000 to 60,000 psi). A liquid, often water or oil, is used as the pressure medium.

Warm Isostatic Pressing (WIP)

WIP is used for materials that benefit from moderate heating to improve their compaction.

It operates at lower pressures than CIP, typically around 300 MPa (approximately 3,000 bar), but at elevated temperatures up to 93°C (200°F).

Hot Isostatic Pressing (HIP)

HIP combines high pressure with very high temperatures to achieve full densification and eliminate internal porosity in materials like metals and ceramics.

This process uses a heated inert gas, such as argon, as the pressure medium. The combination of heat and pressure allows for plastic deformation and diffusion bonding at a microscopic level.

Understanding the Key Trade-offs

Choosing the right isostatic pressing method involves balancing cost, complexity, and the desired final properties of the component.

The Pressure Medium Matters

The medium used to transmit pressure is a critical factor. CIP uses inexpensive and straightforward liquids like water.

HIP, in contrast, requires expensive inert gases like argon or nitrogen, which must be contained and heated in a more complex and costly pressure vessel.

The Role of Temperature

Adding heat significantly increases the complexity and cost of the equipment. CIP is relatively simple, while HIP requires sophisticated furnaces built inside the pressure vessel.

The decision to add heat is driven entirely by the material's properties and the need to achieve near-100% theoretical density, which is often impossible with cold pressing alone.

Freedom of Design

A major advantage of all isostatic methods is design flexibility. Unlike uniaxial pressing, the height-to-diameter ratio of a part is not a limiting factor. This allows for the creation of long, thin, or unusually shaped components with uniform density.

Making the Right Choice for Your Goal

The optimal pressure and method depend entirely on your material and performance requirements.

- If your primary focus is cost-effective consolidation of powders at room temperature: Cold Isostatic Pressing (CIP) is the most direct and economical choice for achieving high, uniform green density.

- If your primary focus is achieving maximum density and eliminating all internal voids in metals or ceramics: Hot Isostatic Pressing (HIP) is the necessary choice, as the combination of heat and pressure is required for full consolidation.

- If your primary focus is processing polymers or composites that require moderate heat for plasticity: Warm Isostatic Pressing (WIP) provides a specialized middle ground between the two extremes.

Ultimately, understanding the interplay between your material's behavior, pressure, and temperature is the key to successfully applying this powerful technology.

Summary Table:

| Method | Typical Pressure Range | Typical Temperature | Primary Use Case |

|---|---|---|---|

| Cold Isostatic Pressing (CIP) | 1,035 - 4,138 bar (15,000 - 60,000 psi) | Ambient (up to 25°C) | Cost-effective consolidation of powders; uniform green density |

| Warm Isostatic Pressing (WIP) | ~3,000 bar (~300 MPa) | Up to 93°C (200°F) | Processing polymers/composites requiring moderate heat |

| Hot Isostatic Pressing (HIP) | Varies (Combined with high heat) | Very High Temperatures | Achieving full density; eliminating porosity in metals/ceramics |

Ready to Achieve Superior Material Density and Performance?

Understanding the precise pressure and temperature requirements for your specific material is the first step toward producing components with exceptional uniformity and strength. Whether your project calls for the cost-effective consolidation of Cold Isostatic Pressing (CIP) or the full densification capabilities of Hot Isostatic Pressing (HIP), KINTEK is your trusted partner.

We specialize in providing robust lab equipment and consumables tailored to your pressing needs, helping you:

- Eliminate internal voids and stress for more reliable parts.

- Process complex geometries with uniform density from all directions.

- Select the optimal method (CIP, WIP, or HIP) based on your material and performance goals.

Let our experts guide you to the perfect solution. Contact KINTEL today to discuss how our isostatic pressing expertise can enhance your laboratory's capabilities and drive your research forward.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the specific function of a cold isostatic press in the sintering process of LiFePO4? Maximize Battery Density

- What is the significance of the Cold Isostatic Press (CIP)? Optimize Lithium-Filled LLZO Composite Anode Preparation

- Why Use Cold Isostatic Press (CIP) for MgAl2O4 After Dry Pressing? Achieve Flawless Transparency

- How much does an isostatic press cost? A Guide to Lab vs. Industrial Pricing

- How do isostatic presses work? Achieve Uniform Density with Isostatic Pressing

- How does the microstructural characterization of gas-atomized powders guide HIP? Optimize Material Integrity

- How does an isostatic press compare to a uniaxial press for Li3PS4 & Na3PS4? Find the Optimal Densification Method

- What products are made from cold isostatic pressing? Achieve Uniform Density in Complex Parts