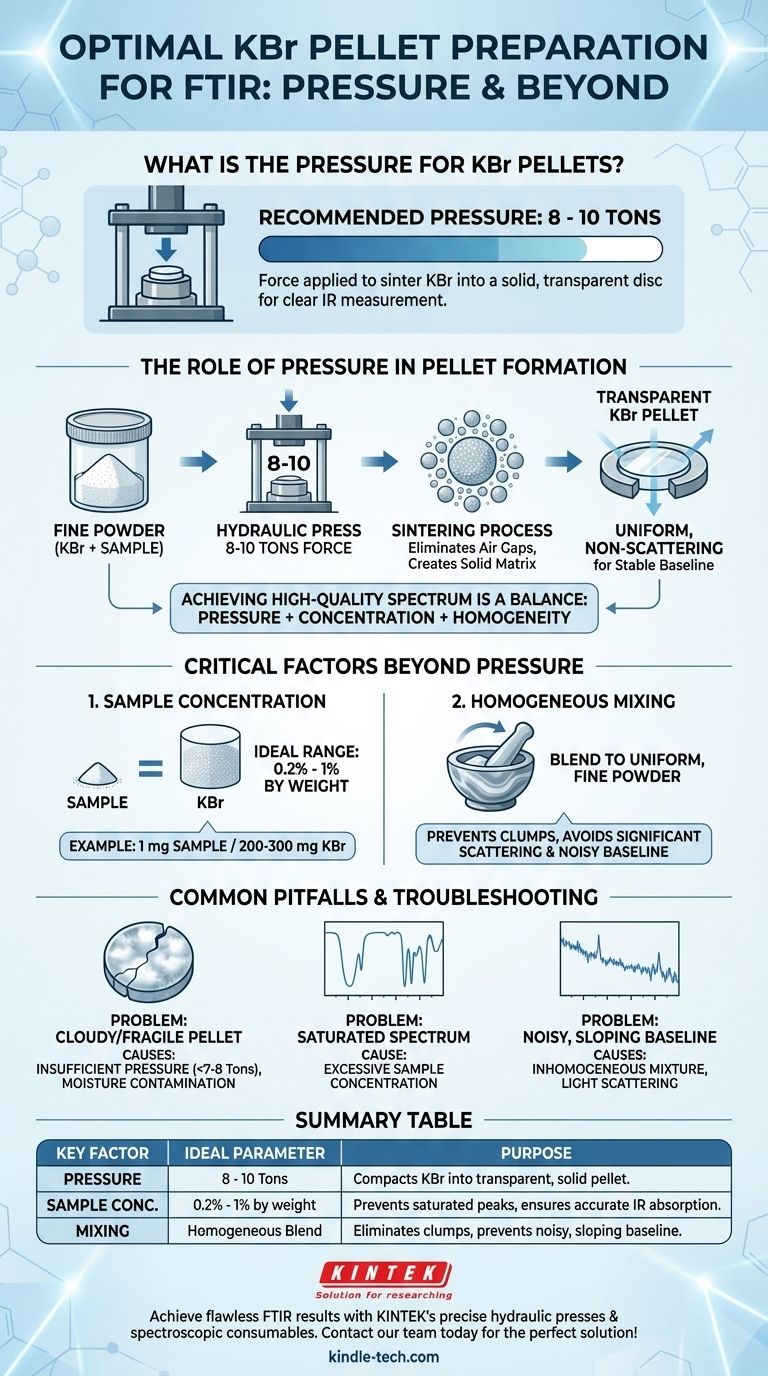

For creating KBr pellets suitable for spectroscopic analysis, the recommended pressure is typically between 8 and 10 tons. This force is applied to a die containing a mixture of your sample and potassium bromide (KBr) powder. The goal is to sinter the KBr into a solid, transparent disc that allows infrared light to pass through with minimal scattering, enabling a clear measurement of your sample.

Achieving a high-quality spectrum is not just about pressure. Success depends on a careful balance between the applied force, the correct sample-to-KBr concentration, and the homogeneity of the mixture.

The Role of Pressure in Pellet Formation

The primary function of the hydraulic press in this process is to transform a fine powder into a solid, glass-like medium. This physical transformation is critical for good spectroscopic results.

Achieving Transparency and Uniformity

Applying 8 to 10 tons of force compacts the KBr powder, eliminating air gaps between the salt crystals. This process, known as sintering, creates a solid matrix that is transparent to infrared radiation. A uniform, non-scattering pellet ensures a stable, flat baseline in your final spectrum.

The Standard Equipment

This pressure is typically achieved using a manual or automated hydraulic press. These devices are built to deliver high, controlled force safely and are a standard piece of equipment in analytical labs performing FTIR (Fourier-transform infrared) spectroscopy.

Beyond Pressure: Critical Factors for a Good Spectrum

While pressure is a key variable, it is often not the source of a poor-quality spectrum. Two other factors are far more common points of failure.

Sample Concentration is Paramount

The concentration of your sample within the KBr is the most critical variable to control. The ideal range is between 0.2% and 1% by weight.

A common and effective recipe for a standard 13mm die is 1 mg of sample mixed with 200-300 mg of spectroscopic-grade KBr. Because the solid pellet is much thicker than a typical liquid sample cell, a very low concentration is required.

The Importance of Homogeneous Mixing

The sample and KBr powder must be blended into a completely uniform, fine powder. This is typically done with an agate mortar and pestle.

If the sample is not evenly dispersed, clumps will cause significant scattering of the IR beam. This results in a noisy, sloping baseline and makes the resulting spectrum difficult or impossible to interpret accurately.

Understanding the Trade-offs and Common Pitfalls

Understanding what happens when you deviate from the ideal process helps in troubleshooting common problems.

Problem: The Cloudy or Fragile Pellet

A pellet that appears opaque, cloudy, or crumbles easily is a clear sign of a problem. This is most often caused by insufficient pressure (below ~7-8 tons) or moisture contamination in the KBr. KBr is hygroscopic (absorbs water from the air) and must be kept perfectly dry.

Problem: The Saturated Spectrum

If your spectrum shows broad, "flat-topped" absorption bands where no light passes through, the cause is almost always excessive sample concentration. The IR beam is being completely absorbed by the sample, providing no useful data. The solution is to remake the pellet with significantly less sample.

Problem: The Noisy, Sloping Baseline

A spectrum with a noisy or steeply sloped baseline is typically caused by light scattering. The two main causes are an inhomogeneous sample mixture (clumps of analyte) or a cloudy pellet that was not pressed with enough force.

Making the Right Choice for Your Analysis

Use these guidelines to troubleshoot your pellet preparation and achieve a high-quality spectrum.

- If your primary focus is a textbook-perfect, transparent pellet: Use 8-10 tons of pressure, keep your sample concentration low (~0.5%), and ensure your KBr powder is bone-dry.

- If your pellet is cloudy or breaks easily: Increase the applied pressure to at least 8 tons and consider gently drying your KBr in an oven before use.

- If your spectrum is noisy or has saturated peaks: Drastically reduce your sample concentration, as this is the most likely cause of poor spectral quality.

Ultimately, mastering KBr pellet preparation is about controlling these few key variables to create a flawless optical window for your sample.

Summary Table:

| Key Factor | Ideal Parameter | Purpose |

|---|---|---|

| Pressure | 8 - 10 tons | Compacts KBr powder into a transparent, solid pellet. |

| Sample Concentration | 0.2% - 1% by weight (e.g., 1 mg sample / 200-300 mg KBr) | Prevents saturated peaks and ensures accurate IR absorption. |

| Mixing | Homogeneous blend with mortar and pestle | Eliminates clumps to prevent a noisy, sloping baseline. |

Achieve flawless FTIR results with confidence. KINTEK specializes in the precise lab equipment you need for reliable KBr pellet preparation, including hydraulic presses and spectroscopic-grade consumables. Let our expertise support your laboratory's success. Contact our team today to find the perfect solution for your analytical needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- kbr pellet press 2t

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How do you prepare KBr pellets for IR? Master the Technique for Clear, Accurate Spectra

- What are the disadvantages of KBr pellets? Avoid Moisture & Prep Errors in FTIR Analysis

- How do you prepare XRF samples? Master the Two Key Methods for Accurate Results

- Why is KBr inactive in IR? The Key to Transparent Sample Analysis

- How do laboratory hydraulic presses facilitate biomass pelletization? Optimize Biofuel Density and Prevent Slagging

- What role does a laboratory hydraulic press play in SDC-carbonate cold pressing? Optimize Electrolyte Densification

- How can a laboratory hydraulic press be applied to chitosan for wastewater treatment? Optimize Pores & Strength

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law