The pressure inside a pellet machine isn't a single, fixed number. Instead, it is an immense and dynamic mechanical force generated when rollers press raw material through the holes of a thick metal plate called a die. This process creates the intense compression and friction needed to form dense, stable pellets from materials like wood or animal feed.

The critical factor in a pellet machine is not a measurable fluid pressure (like PSI), but the mechanical force and friction generated by the roller-and-die system. This system creates the necessary heat and compression to bind the material into a solid pellet.

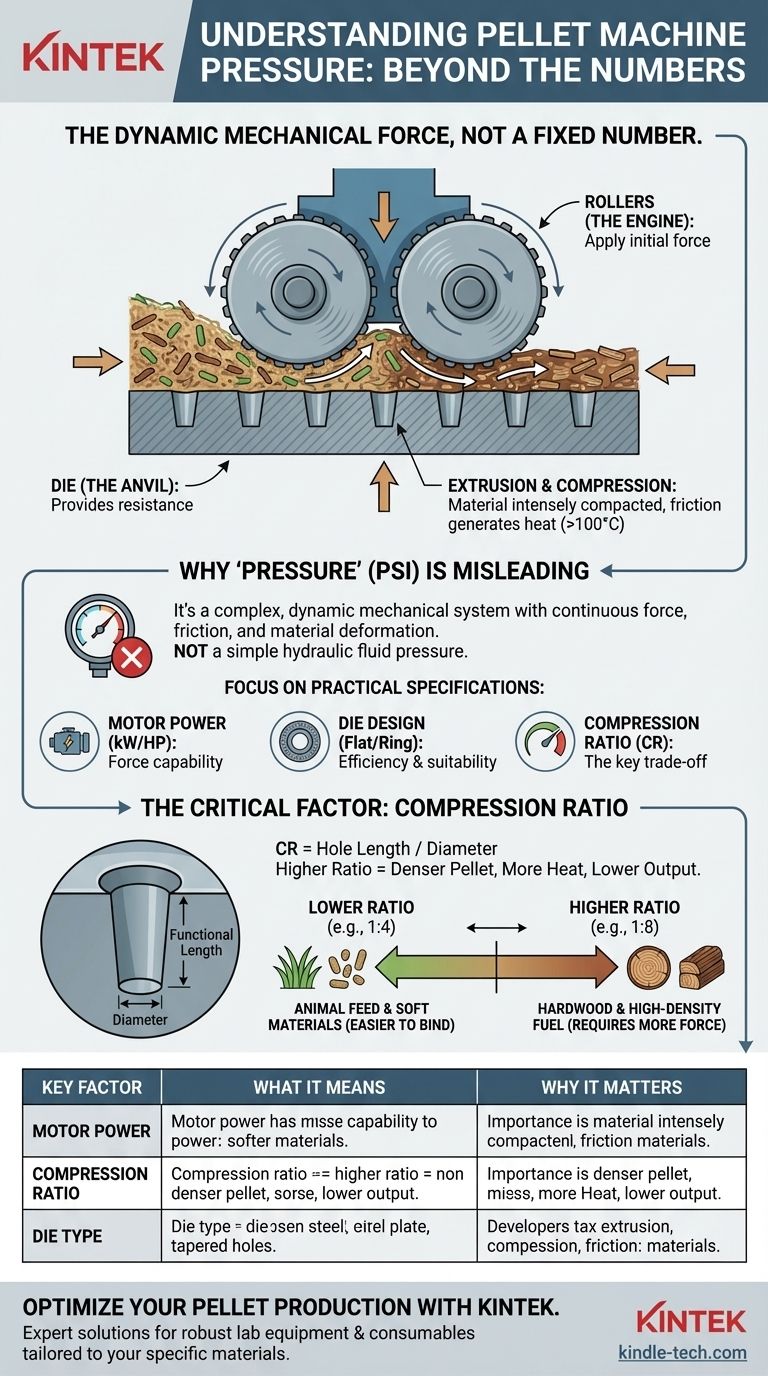

How a Pellet Machine Generates Force

To understand the "pressure" in a pellet machine, you must understand its core mechanical components. The entire operation is a process of extreme compression and extrusion.

The Role of the Rollers

The rollers are the engine of the process. Driven by a powerful motor, they continuously turn and press down on the layer of raw material that is fed onto the die. This is the initial application of force.

The Function of the Die

The die is a heavy, stationary steel disc perforated with hundreds of small, tapered holes. It acts as the anvil, providing the resistance against which the rollers push the material.

The Extrusion and Compression Process

The real magic happens inside the die holes. As the rollers force the raw material into the holes, the material becomes intensely compacted. The geometry of the hole, which is often longer than it is wide, dictates the level of compression.

Heat from Friction

This intense compression and friction generate significant heat, often exceeding 100°C (212°F). This heat is not a byproduct; it is essential. For wood, it softens the natural lignin, which then acts as a glue to bind the sawdust particles together. For animal feed, it helps gelatinize starches, improving digestibility and pellet durability.

Why "Pressure" Is a Misleading Metric

You will rarely, if ever, see a pellet machine advertised with a specific pressure rating like PSI or Pascals. This is because the concept doesn't apply cleanly to this type of mechanical system.

A Dynamic Mechanical System

A pellet mill is not a hydraulic press, where fluid pressure is uniform and easily measured. It's a system of continuous mechanical force, dynamic friction, and material deformation. The force varies constantly based on the material feed rate and its consistency.

Focus on Practical Specifications

Instead of looking for a pressure rating, an operator or buyer should focus on more meaningful specifications. These numbers provide a much clearer picture of the machine's capabilities and suitability for a given task.

Key Metrics to Evaluate

The most important specifications are the motor power (in kW or HP), the die design (flat vs. ring), and the die compression ratio. The motor power indicates the force available, while the compression ratio tells you how much the material will be compacted.

Understanding the Key Trade-off: The Compression Ratio

The single most important factor that determines the machine's force and the quality of the final pellet is the die's compression ratio.

Defining the Ratio

The compression ratio is the ratio of the functional length of the die hole to its diameter. A higher ratio means a longer channel for a given diameter, resulting in more friction, more heat, and a denser pellet.

The Impact on Materials

Different materials require different compression ratios. Soft materials like grasses or animal feed require lower ratios. Hard materials like dense hardwood sawdust require very high compression ratios to generate enough heat and force to bind properly.

The Trade-off with Output

Using a die with a higher compression ratio will produce denser, higher-quality pellets, but it also requires more motor power and will result in a lower output (kg per hour). The material spends more time in the die and meets more resistance, slowing the process down.

Making the Right Choice for Your Goal

Selecting the right machine configuration is about matching the equipment's force-generating capability to the specific requirements of your raw material.

- If your primary focus is making animal feed: A machine with a lower compression ratio die is often sufficient, as starches bind more easily than wood lignin.

- If your primary focus is making pellets from softwoods or grasses: A standard machine with a moderate compression ratio (e.g., 1:6) will likely be effective.

- If your primary focus is making high-density fuel pellets from hardwood: You will need a heavy-duty machine with significant motor power and a high compression ratio die (e.g., 1:7 or higher) to overcome the material's resistance.

Ultimately, understanding the interplay between motor power, die design, and your specific raw material is the true key to successful pellet production.

Summary Table:

| Key Factor | What It Means | Why It Matters |

|---|---|---|

| Motor Power | The energy (kW/HP) driving the rollers. | Determines the machine's overall force capability. |

| Compression Ratio | Die hole length vs. diameter (e.g., 1:6). | Dictates pellet density and quality; higher ratio = denser pellets. |

| Die Type | Flat or ring die design. | Affects efficiency and suitability for different materials. |

Ready to Optimize Your Pellet Production?

Understanding the dynamic forces in a pellet machine is key to achieving high-quality, durable pellets. At KINTEK, we specialize in providing robust lab equipment and consumables tailored to your pelletizing needs—whether for biomass, animal feed, or research applications.

Our experts can help you select the right machinery with the ideal motor power and die configuration for your specific materials. Let us enhance your efficiency and output quality.

📞 Contact us today to discuss your project and discover how KINTEK's solutions can drive your success!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- How is a hydraulic press helpful for making KBr pellets? Achieve Superior FTIR Sample Preparation

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques

- Why is KBr used as a mulling agent in IR? Achieve Clear, Accurate Solid Sample Analysis