At its core, Physical Vapor Deposition (PVD) is a sophisticated vacuum-coating process. It works by turning a solid material into a vapor, which then travels through a vacuum and condenses, atom by atom, onto the surface of an object. This method creates an extremely thin, durable, and tightly bonded film that fundamentally enhances the properties of the underlying material.

The central principle of PVD is not to apply a layer on top of a surface, but to build a new surface at the molecular level. This vacuum-based deposition process creates a film that is bonded to the substrate, resulting in superior durability and performance compared to traditional plating or painting.

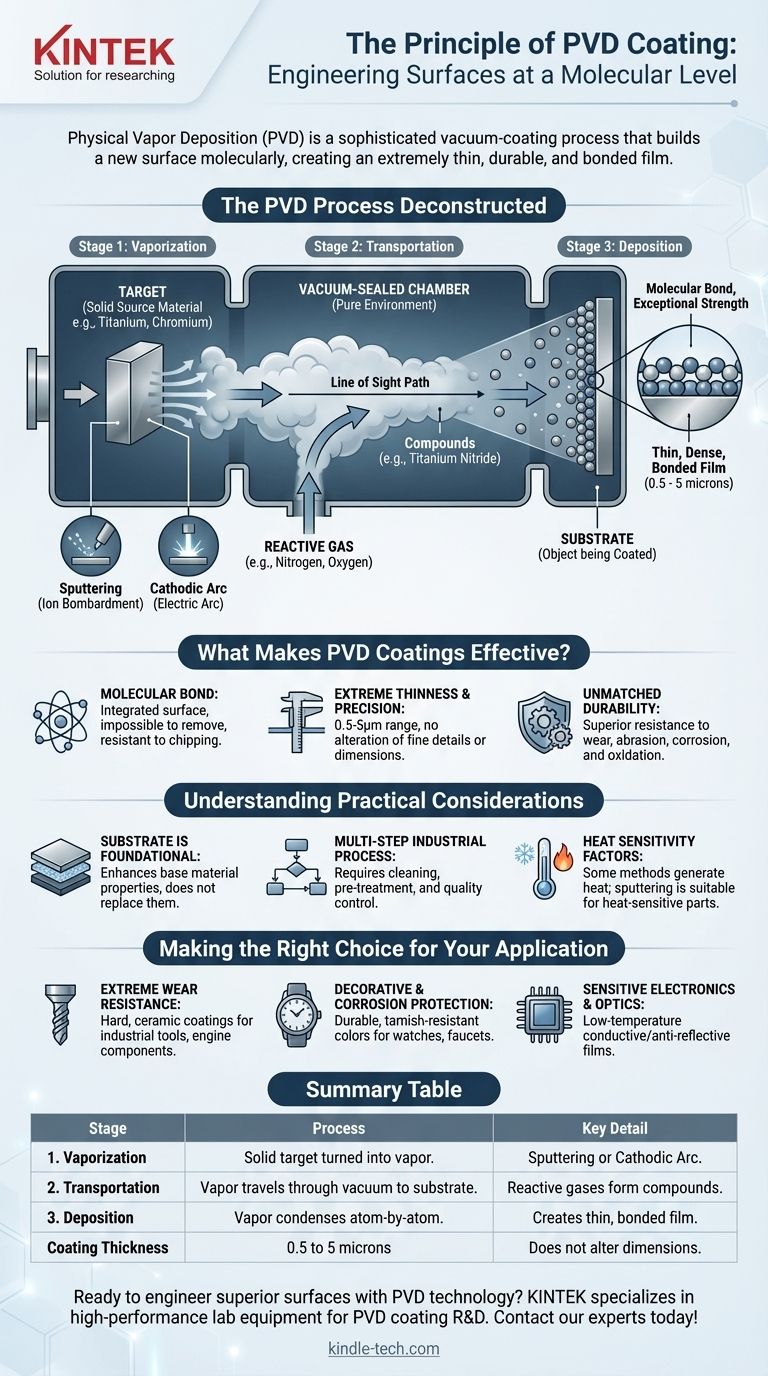

The PVD Process Deconstructed

To truly understand PVD, it's best to break it down into its three critical stages. The entire process takes place inside a high-vacuum chamber, which is essential for the purity and quality of the final coating.

The Essential Role of the Vacuum

The process must occur in a vacuum to eliminate any foreign particles, such as oxygen or water vapor. This ensures the vaporized coating material doesn't react with anything in the air before it reaches the target object, guaranteeing a pure and perfectly bonded film.

Stage 1: Vaporization

First, a solid source material, known as a target, must be converted into a gaseous vapor. This target is made of the material you wish to coat with, such as titanium, chromium, or zirconium.

Common methods for vaporization include sputtering, where the target is bombarded with high-energy ions, or using a cathodic arc, which uses an electric arc to vaporize the material.

Stage 2: Transportation

Once vaporized, the cloud of atoms or ions travels through the vacuum-sealed chamber from the target to the object being coated (the substrate). The path is a straight line of sight, which is why proper positioning and fixturing of parts is critical.

During this stage, a reactive gas like nitrogen or oxygen can be introduced. This allows the vaporized metal to react and form ceramic compounds (like titanium nitride), dramatically altering the coating's properties, such as color and hardness.

Stage 3: Deposition

When the vaporized atoms strike the substrate, they condense back into a solid state. This happens atom by atom, building up a thin, dense, and highly uniform film. Because this occurs at a molecular level, the coating adheres with exceptional strength.

What Makes PVD Coatings So Effective?

The principle behind the process directly leads to its unique and valuable characteristics. PVD isn't just another finish; it's a form of surface engineering.

A Molecular Bond, Not a Layer of Paint

The deposition process creates a bonded layer that is integrated with the substrate's surface. This is why PVD coatings are nearly impossible to remove and are exceptionally resistant to chipping or flaking.

Extreme Thinness and Precision

PVD coatings are remarkably thin, typically ranging from just 0.5 to 5 microns. This means they can be applied without altering the fine details, surface texture, or functional dimensions of the underlying part.

Unmatched Durability

The resulting films are incredibly hard and dense. This gives them superior resistance to wear, abrasion, corrosion, and oxidation, significantly extending the life of the coated object.

Understanding the Practical Considerations

While powerful, the PVD process is not a universal solution. Its effectiveness is tied to specific conditions and requirements that must be understood.

Substrate Is Foundational

A PVD coating enhances the properties of the base material, but it does not replace them. The final performance, including fatigue limit and endurance, is a combination of both the coating and the underlying substrate. A high-performance coating cannot fix a poor-quality base material.

A Multi-Step Industrial Process

The deposition itself is only one part of a larger workflow. A successful PVD application requires meticulous preparation, including part cleaning, pre-treatment, and quality control, followed by careful fixturing within the chamber.

Heat Sensitivity Can Be a Factor

Some PVD techniques generate significant heat. However, specific methods like sputtering operate at very low temperatures, making them suitable for heat-sensitive materials like plastics, electronics, or even biological samples for microscopy.

Making the Right Choice for Your Application

The versatility of PVD allows it to be tailored to achieve specific outcomes. Your end goal will determine how the process is best applied.

- If your primary focus is extreme wear resistance: PVD is used to apply hard, ceramic-based coatings like Titanium Nitride (TiN) to industrial tools, drills, and engine components, dramatically increasing their lifespan.

- If your primary focus is a decorative finish and corrosion protection: PVD provides durable, tarnish-resistant colors on items like watches, faucets, and jewelry, far outlasting traditional plating.

- If your primary focus is coating sensitive electronics or optics: Low-temperature PVD processes like sputtering can apply conductive or anti-reflective films without damaging the delicate underlying components.

Ultimately, Physical Vapor Deposition is a precise and powerful tool for engineering surfaces with properties that are simply unachievable with conventional methods.

Summary Table:

| Stage | Process | Key Detail |

|---|---|---|

| 1. Vaporization | Solid target material is turned into a vapor. | Achieved via sputtering or cathodic arc. |

| 2. Transportation | Vapor travels through a vacuum to the substrate. | Reactive gases can be introduced to form compounds. |

| 3. Deposition | Vapor condenses atom-by-atom onto the substrate. | Creates a thin, dense, and strongly bonded film. |

| Coating Thickness | 0.5 to 5 microns | Does not alter part dimensions. |

Ready to engineer superior surfaces with PVD technology?

KINTEK specializes in high-performance lab equipment, including systems for PVD coating research and development. Whether you need to enhance wear resistance for industrial tools, apply durable decorative finishes, or coat sensitive electronics, our solutions are designed for precision and reliability.

Contact our experts today to discuss how our PVD systems and consumables can meet your specific laboratory and manufacturing needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

People Also Ask

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What does PVD sputtering mean? A Guide to High-Performance Thin Film Deposition

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What is the RF frequency for sputtering? Unlocking the Standard for Insulating Materials