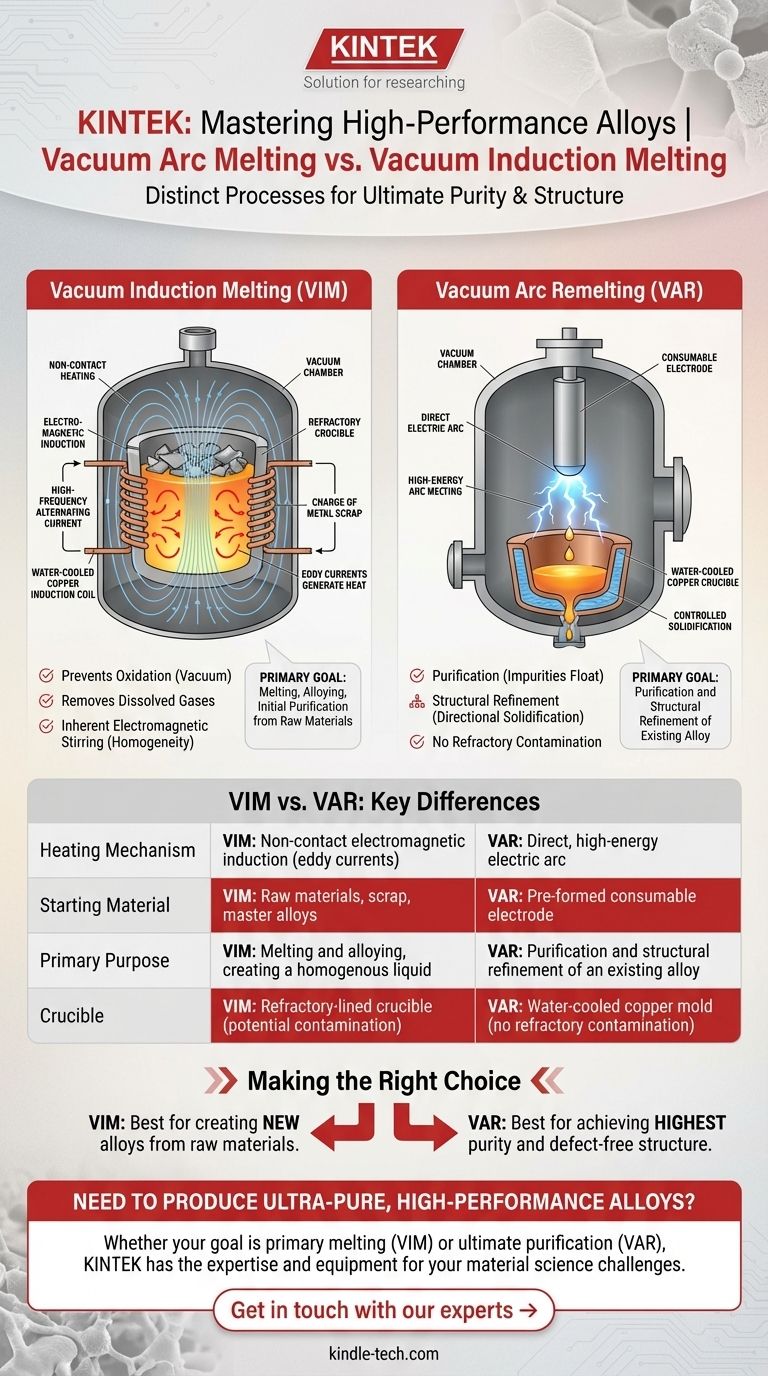

To be precise, the principle you are asking about, Vacuum Arc Melting, is distinct from the process described in the provided references, which is Vacuum Induction Melting. Vacuum Induction Melting (VIM) uses electromagnetic eddy currents to heat and melt metal inside a refractory crucible within a vacuum. The vacuum environment prevents contamination from atmospheric gases like oxygen and nitrogen, which is critical for reactive metals and high-purity alloys.

The core distinction you need to understand is this: Vacuum Induction Melting uses a non-contact magnetic field to melt metals, while Vacuum Arc Remelting uses a high-energy electric arc—like a controlled lightning strike—to remelt an existing metal electrode for ultimate purification.

Understanding Vacuum Induction Melting (VIM)

Vacuum Induction Melting is a primary melting process used to create high-quality alloys from raw materials in a highly controlled environment.

The Induction Principle

The heart of VIM is electromagnetic induction. A crucible containing the solid metal charge is placed inside a powerful, water-cooled copper coil.

When a high-frequency alternating current is passed through this coil, it generates a powerful and rapidly changing magnetic field.

This magnetic field penetrates the metal charge and induces strong electrical currents within it, known as eddy currents. The inherent electrical resistance of the metal causes these eddy currents to generate immense heat, melting the material from the inside out without any direct contact from a heat source.

The Role of the Vacuum

The entire process takes place inside a sealed, airtight chamber from which the air has been removed. This vacuum serves two critical functions.

First, it prevents oxidation and contamination. Many advanced alloys and reactive metals (like titanium or superalloys) would be ruined by reacting with oxygen or nitrogen in the air at high temperatures.

Second, the vacuum helps remove dissolved gas impurities from the molten metal, such as hydrogen and nitrogen, leading to a cleaner and more structurally sound final product.

Inherent Stirring and Homogeneity

A key benefit of the induction process is the natural electromagnetic stirring it creates in the molten metal bath.

This constant motion ensures that alloying elements are mixed thoroughly and evenly, resulting in a final product with a highly uniform and consistent chemical composition.

The Principle of Vacuum Arc Remelting (VAR)

While VIM creates a high-quality initial melt, Vacuum Arc Remelting (VAR) is a secondary process designed to take that quality to an even higher level through purification and controlled solidification.

The Consumable Electrode

The VAR process does not start with raw scrap metal. Instead, it begins with a solid, cylindrical piece of metal called a consumable electrode, which is often cast from a VIM furnace.

This electrode is suspended inside a water-cooled copper crucible within a vacuum chamber.

Generating the Electric Arc

A powerful DC current is applied, and an electric arc is struck between the bottom of the electrode and a small amount of starter metal at the base of the crucible.

The intense energy of this arc, reaching thousands of degrees, progressively melts the tip of the electrode.

Progressive Solidification and Purification

As the electrode melts, droplets of metal fall into the water-cooled copper crucible below, where they immediately begin to solidify. The melt pool is kept small and solidifies in a highly controlled, directional manner from the bottom up.

This process forces impurities, such as oxides and nitrides, to float to the top of the small molten pool, where they are pushed to the edge of the final ingot. The result is a refined metal with exceptionally high purity and a superior grain structure.

VIM vs. VAR: Understanding the Key Differences

Choosing the right process depends entirely on the goal. They are often used in sequence but serve fundamentally different purposes.

Heating Mechanism

VIM uses non-contact electromagnetic induction to generate heat within the bulk material. VAR uses a direct, high-energy electric arc to melt the surface of an electrode.

Starting Material

VIM can melt a variety of raw materials, including scrap, pure metals, and master alloys, which are loaded directly into its crucible. VAR requires a pre-formed consumable electrode of the desired alloy.

Primary Purpose

The primary purpose of VIM is melting and alloying—creating a homogenous liquid metal of a specific chemical composition. The primary purpose of VAR is purification and structural refinement of an existing alloy.

Interaction with a Crucible

In VIM, the molten metal is held in a refractory-lined crucible, which can be a potential source of ceramic inclusions. In VAR, the metal solidifies in a water-cooled copper mold, which avoids this refractory contamination entirely.

Making the Right Choice for Your Goal

Understanding these differences is key to specifying the correct manufacturing process for high-performance materials.

- If your primary focus is creating a new alloy from raw materials: VIM is the correct and necessary first step for its ability to melt, mix, and provide initial purification.

- If your primary focus is achieving the highest purity and a defect-free internal structure: VAR is the essential secondary step used to refine a VIM-produced electrode for critical applications like aerospace or medical implants.

Ultimately, these two processes represent a powerful combination for producing the cleanest and most reliable metals available today.

Summary Table:

| Process | Heating Method | Starting Material | Primary Goal | Crucible Type |

|---|---|---|---|---|

| Vacuum Induction Melting (VIM) | Electromagnetic induction (eddy currents) | Raw materials, scrap, master alloys | Melting, alloying, initial purification | Refractory-lined crucible |

| Vacuum Arc Remelting (VAR) | High-energy electric arc | Pre-formed consumable electrode | Purification, structural refinement | Water-cooled copper mold |

Need to produce ultra-pure, high-performance alloys?

Whether your goal is primary melting and alloying with Vacuum Induction Melting (VIM) or achieving ultimate purification and structural refinement with Vacuum Arc Remelting (VAR), KINTEK has the expertise and equipment to meet your laboratory's most demanding material science challenges.

Contact us today to discuss how our specialized lab solutions can help you create cleaner, more reliable metals for critical applications in aerospace, medical, and advanced manufacturing.

Get in touch with our experts →

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is the VAR melting process? The Ultimate Guide to Vacuum Arc Remelting

- What is the remelting process? Achieve Ultimate Purity and Performance for High-Strength Alloys

- What is a remelting process? A Guide to High-Purity Metal Refinement

- What is the vacuum arc remelting process? Producing Ultra-Pure, High-Performance Metal Alloys

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity