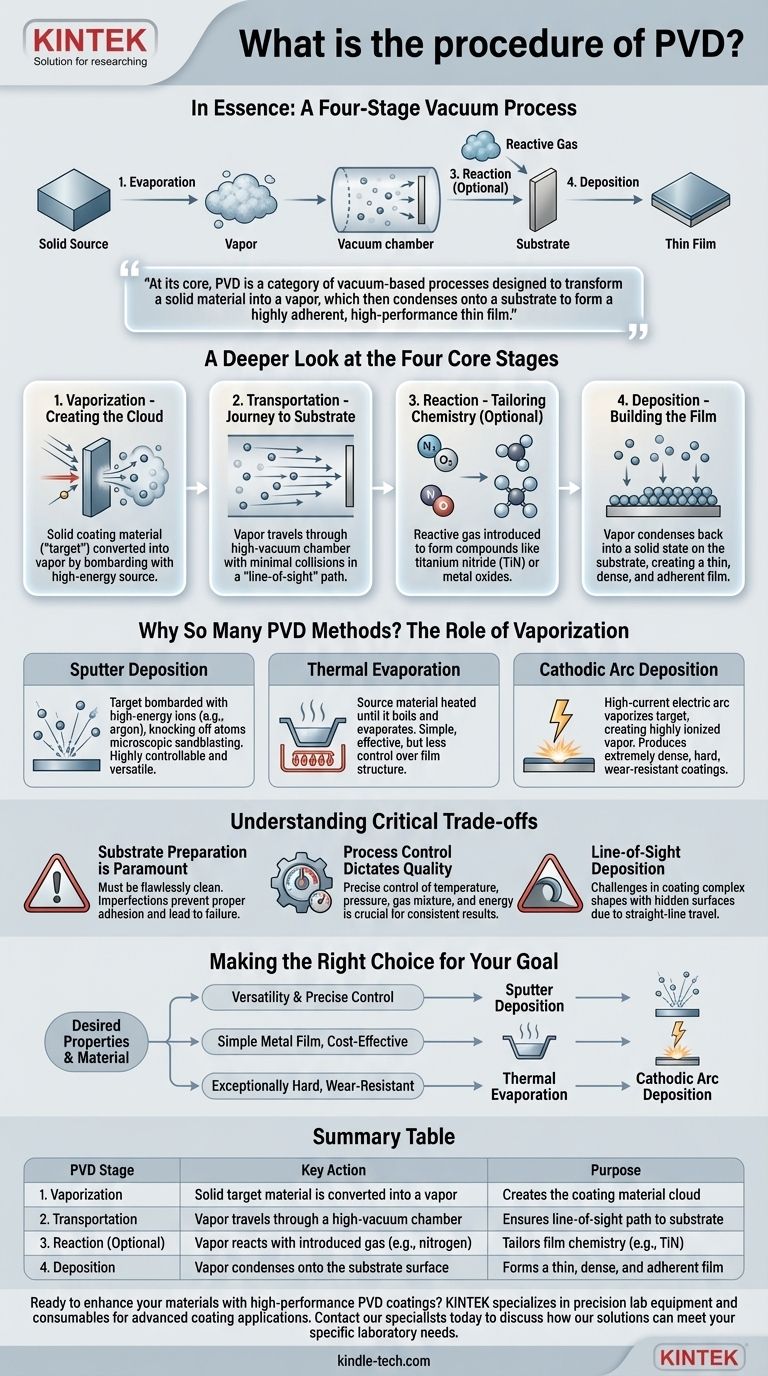

In essence, the Physical Vapor Deposition (PVD) procedure is a four-stage process conducted in a vacuum. It begins with creating a vapor from a solid source material (Evaporation), moving that vapor to the object being coated (Transportation), sometimes reacting it with a gas to form a new compound (Reaction), and finally condensing the vapor onto the object to form a thin, durable film (Deposition).

At its core, PVD is not a single procedure but a category of vacuum-based processes designed to transform a solid material into a vapor, which then condenses onto a substrate to form a highly adherent, high-performance thin film. The specific method used to create that vapor is what differentiates the various PVD techniques.

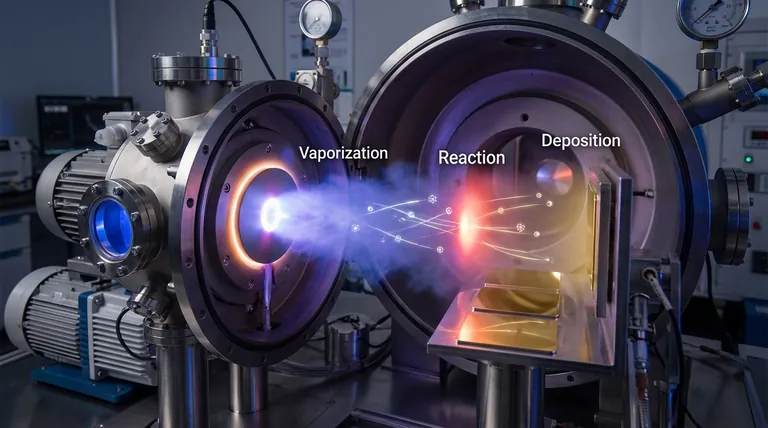

A Deeper Look at the Four Core Stages

While the four-step model provides a clear framework, understanding what happens in each stage is crucial to grasping how PVD achieves its results.

Stage 1: Vaporization - Creating the Coating Material Cloud

This is the foundational step where a solid coating material, known as the "target," is converted into a vapor. The method used to achieve this is the primary distinction between different PVD technologies. This is typically done by bombarding the target with a high-energy source, such as ions or an electron beam, to dislodge atoms.

Stage 2: Transportation - The Journey to the Substrate

Once vaporized, the atoms or molecules of the coating material travel through a high-vacuum chamber. The vacuum is critical because it ensures there are minimal other gas particles for the vapor to collide with, allowing it to travel in a straight "line-of-sight" path to the substrate (the part being coated).

Stage 3: Reaction - Tailoring the Film's Chemistry (Optional)

For certain applications, a reactive gas like nitrogen, oxygen, or acetylene is introduced into the chamber. The vaporized metal atoms react with this gas during transport to form a compound material on the substrate's surface. This is how coatings like titanium nitride (TiN) or metal oxides are created.

Stage 4: Deposition - Building the Thin Film

Upon reaching the substrate, the vapor condenses back into a solid state. It builds up on the surface atom by atom, creating a thin, dense, and highly adherent film. The properties of the final coating are determined by the process parameters in all four stages.

Why So Many PVD Methods? The Role of Vaporization

The list of PVD techniques—sputtering, evaporation, cathodic arc—can be confusing. The key is to recognize that they are all variations of the same four-stage process, differing almost entirely in how they accomplish Stage 1: Vaporization.

Sputter Deposition

In sputtering, the target material is bombarded with high-energy ions (usually of an inert gas like argon). This acts like a microscopic sandblaster, knocking atoms off the target material and ejecting them toward the substrate. It is a highly controllable and versatile method.

Thermal Evaporation

This is one of the simplest PVD methods. The source material is heated in the vacuum chamber until it begins to boil and evaporate, creating a vapor that then condenses on the cooler substrate. While effective, it offers less control over film structure compared to sputtering.

Cathodic Arc Deposition

This method uses a high-current electric arc to vaporize the target material. The process generates a highly ionized vapor, resulting in extremely dense and hard coatings. It is exceptionally effective for creating wear-resistant films on tools.

Understanding the Critical Trade-offs

Achieving a successful PVD coating requires more than just following the steps; it demands a deep understanding of the controlling factors and inherent limitations.

Substrate Preparation is Paramount

The PVD process does not hide imperfections. The substrate must be flawlessly clean and free of any contaminants. Any microscopic dust or oil will prevent the coating from adhering properly, leading to film failure.

Process Control Dictates Quality

The final properties of the coating are directly linked to precise control of variables within the vacuum chamber. Temperature, pressure, gas mixture, and the energy used for vaporization must all be meticulously managed to produce a consistent and high-quality result.

Line-of-Sight Deposition

In most PVD processes, the vapor travels in a straight line from the source to the substrate. This means that coating complex, three-dimensional shapes with hidden surfaces or deep recesses can be challenging without sophisticated part-rotation mechanisms.

Making the Right Choice for Your Goal

Your choice of PVD method depends entirely on the desired properties of the final coating and the material you are depositing.

- If your primary focus is versatility and precise control over film composition: Sputter deposition is often the superior choice due to its excellent control over deposition rates and material alloys.

- If your primary focus is depositing a simple metal film cost-effectively: Thermal evaporation can be a straightforward and efficient method, especially for lower-melting-point materials.

- If your primary focus is creating exceptionally hard and dense wear-resistant coatings: Cathodic arc deposition provides the high-energy ions needed to form these robust films, ideal for cutting tools and demanding applications.

Understanding these core stages and methods is the first step toward leveraging this powerful technology for your specific application.

Summary Table:

| PVD Stage | Key Action | Purpose |

|---|---|---|

| 1. Vaporization | Solid target material is converted into a vapor | Creates the coating material cloud |

| 2. Transportation | Vapor travels through a high-vacuum chamber | Ensures line-of-sight path to substrate |

| 3. Reaction (Optional) | Vapor reacts with introduced gas (e.g., nitrogen) | Tailors film chemistry (e.g., TiN) |

| 4. Deposition | Vapor condenses onto the substrate surface | Forms a thin, dense, and adherent film |

Ready to enhance your materials with high-performance PVD coatings? KINTEK specializes in precision lab equipment and consumables for advanced coating applications. Whether you're developing wear-resistant tools or functional thin films, our expertise ensures you achieve optimal results. Contact our specialists today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process