At its core, coating deposition is a highly controlled process of applying a thin film of material onto a surface, known as a substrate. This is accomplished by first meticulously cleaning the substrate, then vaporizing a source material within a vacuum, and finally allowing that vapor to condense and form a new, functional layer on the substrate's surface, atom by atom.

The key to successful coating deposition is not just the application itself, but the creation of an exceptionally pure environment. The process is fundamentally about removing all contaminants and variables so that a new surface can be engineered with atomic-level precision.

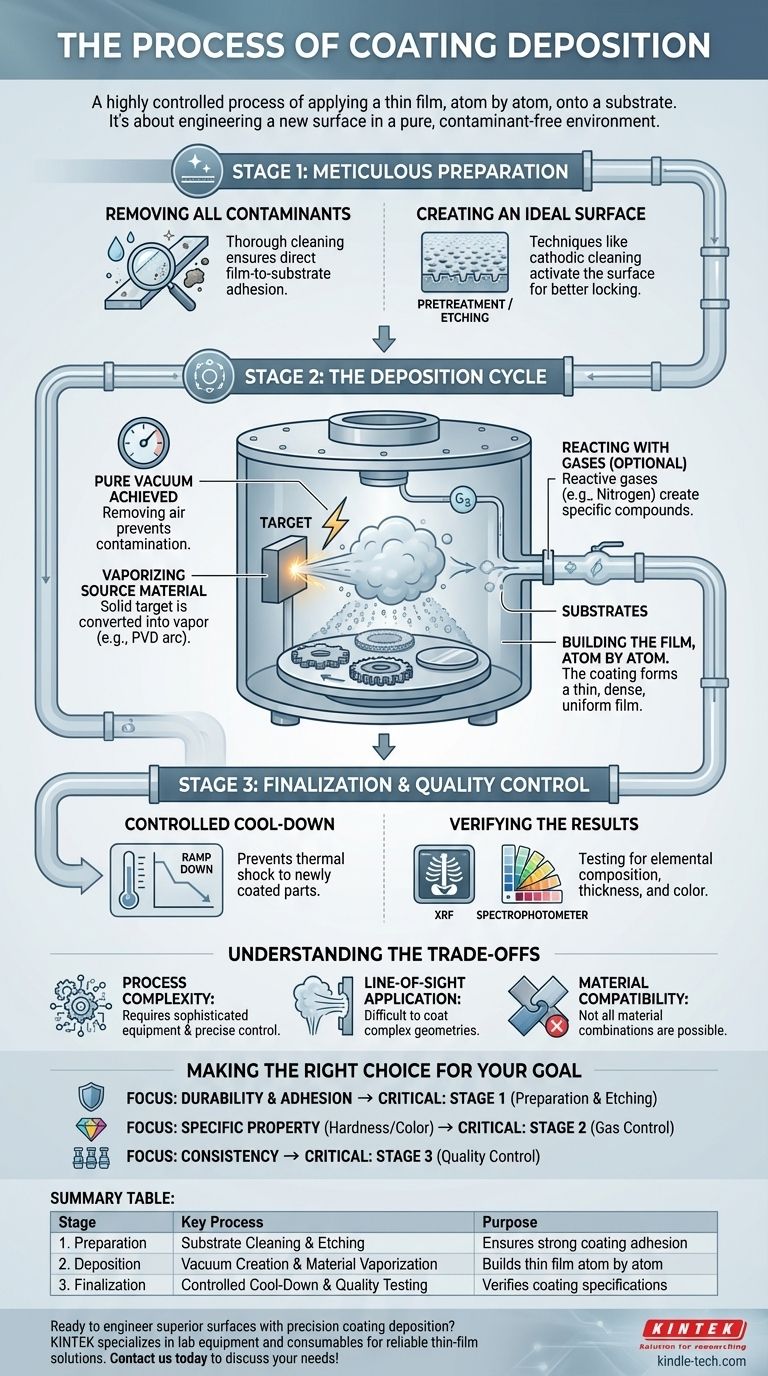

Stage 1: Meticulous Preparation

Before any coating can be applied, the substrate must be in a perfect state to receive it. This preparation phase is arguably the most critical for ensuring the final coating will adhere properly and perform as intended.

Removing All Contaminants

The first step is a thorough cleaning of the substrate. Any oil, grease, dust, or other surface contamination will prevent the coating from forming a strong bond.

This initial cleaning ensures the deposited film adheres directly to the substrate material, not to a layer of debris.

Creating an Ideal Surface

In many processes, simple cleaning is not enough. The substrate may undergo a pretreatment or etching process.

This step uses techniques like cathodic cleaning to microscopically roughen or activate the surface, creating a more receptive foundation for the coating to lock onto.

Stage 2: The Deposition Cycle

With the substrate prepared, it enters a vacuum chamber where the core deposition process occurs. This cycle is defined by precise control over temperature, pressure, and materials.

Achieving a Pure Vacuum

The chamber is sealed and air is pumped out to create a vacuum. This is often called the "ramp up" phase.

Removing air is essential because stray particles (like oxygen or nitrogen) would otherwise react with the vaporized coating material and contaminate the final film, altering its properties.

Vaporizing the Source Material

The solid material intended for the coating, known as the target, is converted into a vapor.

In Physical Vapor Deposition (PVD), this is often done by striking the target with a high-energy electrical arc, which vaporizes and ionizes the metal.

Reacting with Gases (Optional)

To create specific coating compounds with desired properties, reactive gases are introduced into the chamber.

For example, nitrogen gas might be introduced to react with a vaporized titanium target. This forms a titanium nitride compound on the substrate, which is extremely hard and has a characteristic gold color.

Building the Film, Atom by Atom

The vaporized material, now in the form of a plasma or vapor cloud, travels through the vacuum and condenses onto the cooler substrates.

This is the deposition step, where the coating is built up layer by atomic layer, forming a thin, dense, and highly uniform film.

Stage 3: Finalization and Quality Control

Once the desired coating thickness is achieved, the process concludes with a controlled shutdown and verification.

Controlled Cool-Down

The chamber is carefully returned to ambient temperature and pressure in a "ramp down" stage. A controlled cooling system is used to prevent thermal shock to the newly coated parts.

Verifying the Results

Quality control is non-negotiable. Each batch of coated components is tested to ensure it meets the required specifications.

Specialized equipment like an X-ray fluorescent (XRF) machine is used to precisely measure the coating's elemental composition and thickness, while a spectrophotometer can be used to verify its color.

Understanding the Trade-offs

While powerful, deposition processes like PVD have inherent characteristics that must be considered.

Process Complexity

This is not a simple dipping or painting process. It requires sophisticated, expensive equipment and precise control over numerous variables, from vacuum pressure to gas composition.

Line-of-Sight Application

Most vapor deposition methods are "line-of-sight" processes. The vaporized material travels in a straight line, which means it can be difficult to uniformly coat complex internal geometries or deep crevices.

Material Compatibility

The process is defined by the ability to vaporize a source material and have it adhere to a substrate. Certain combinations of materials are more challenging or simply incompatible with this method.

Making the Right Choice for Your Goal

Understanding the steps allows you to focus on the part of the process most critical to your desired outcome.

- If your primary focus is durability and adhesion: Your success depends entirely on the meticulous cleaning and surface pretreatment in Stage 1.

- If your primary focus is achieving a specific property (like hardness or color): The precise control of reactive gases during the deposition cycle in Stage 2 is the most critical factor.

- If your primary focus is consistency across a large batch of parts: A rigorous and repeatable quality control protocol in Stage 3 is non-negotiable.

Ultimately, mastering the deposition process is about systematically controlling an environment to engineer a material's surface for a specific purpose.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Preparation | Substrate Cleaning & Etching | Ensures strong coating adhesion |

| 2. Deposition | Vacuum Creation & Material Vaporization | Builds thin film atom by atom |

| 3. Finalization | Controlled Cool-Down & Quality Testing | Verifies coating specifications |

Ready to engineer superior surfaces with precision coating deposition? KINTEK specializes in lab equipment and consumables for coating processes, serving laboratories that require reliable thin-film solutions. Our expertise ensures your deposition projects achieve optimal adhesion, specific material properties, and consistent batch results. Contact us today to discuss how our solutions can enhance your coating applications!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth