At its core, cold grinding is a size-reduction process where a material is first chilled to an extremely low temperature before being mechanically ground into a fine powder. By using a cryogen like liquid nitrogen, the material becomes brittle, allowing it to fracture cleanly and easily. This method is specifically designed to prevent the heat damage, melting, or degradation that often occurs with traditional grinding methods.

The fundamental problem with conventional grinding is that friction generates heat, which can ruin sensitive materials. Cold grinding solves this by using extreme cold to make the material brittle, enabling a clean break that preserves the product's original quality and chemical integrity.

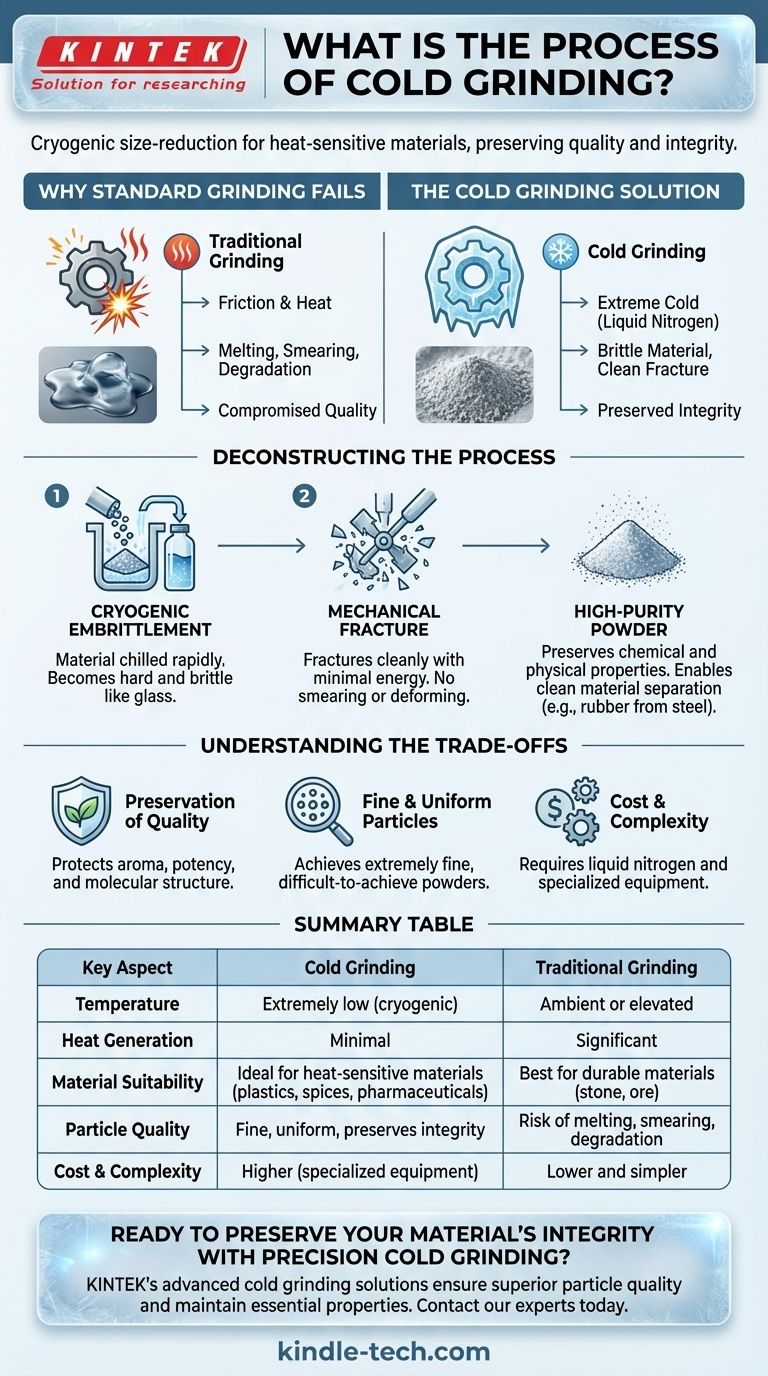

Why Standard Grinding Fails for Sensitive Materials

The Inevitable Problem of Friction and Heat

Traditional grinding relies on mechanical force—crushing, impact, and abrasion—to reduce particle size. This process inherently creates significant friction.

That friction translates directly into heat. For robust materials like stone or ore, this is rarely an issue. For many others, however, this heat is a destructive force.

How Heat Degrades Product Quality

Heat can cause plastics and waxy substances to melt and smear, fouling the equipment and ruining the product.

For materials like spices, pharmaceuticals, or volatile chemicals, heat can destroy the very properties that make them valuable. Aromatic compounds are lost, active ingredients can be denatured, and the final product's quality is compromised.

Deconstructing the Cold Grinding Process

Step 1: Cryogenic Embrittlement

The process begins by feeding the source material, often in the form of chips or coarse crumb, into a cooling system.

A cryogen, most commonly liquid nitrogen, is used to rapidly chill the material. This extreme cold changes its physical state, making it hard and brittle, much like glass.

Step 2: Mechanical Fracture

Once embrittled, the frozen material is immediately transferred into a specialized mill, such as a paddle-type mill.

Because the material is now brittle, the mill can fracture it with minimal energy. Instead of smearing or deforming, the material shatters cleanly into fine particles with smooth fracture surfaces.

The Result: A High-Purity Powder

This process is highly efficient, capable of producing thousands of pounds of product per hour. Critically, it generates very little heat, ensuring the material's original chemical and physical properties remain intact.

This method also excels at material separation. For instance, when grinding scrap tires, the rubber becomes brittle and shatters away from the steel and fiber, allowing for easy and clean separation, which increases the yield of usable, pure rubber.

A Critical Distinction: Grinding vs. Pressing

Cold Grinding Reduces Size

It is crucial to understand that the sole objective of cold grinding is size reduction. The process starts with a larger solid and ends with a fine powder.

Cold Isostatic Pressing Creates Solids

A similarly named but completely different process is cold isostatic pressing. This technique is used for compaction, not grinding.

In cold pressing, a powder is placed in a flexible mold and subjected to immense, uniform liquid pressure. This fuses the powder together to create a dense, solid object. Its goal is the opposite of grinding.

Understanding the Trade-offs

Advantage: Preservation of Quality

The primary benefit is the preservation of product integrity. By eliminating thermal degradation, cold grinding protects the aroma of spices, the potency of pharmaceuticals, and the molecular structure of polymers.

Advantage: Fine and Uniform Particles

The embrittlement process allows for the creation of extremely fine, uniform powders that are difficult to achieve with other methods, especially for elastic or soft materials.

The Trade-off: Cost and Complexity

The main drawback is cost and complexity. Operating a cryogenic system requires specialized equipment like insulated containers, pressure gauges, and nozzles, as well as a continuous supply of liquid nitrogen. This makes the process significantly more expensive than simple ambient grinding.

Making the Right Choice for Your Goal

When deciding if this process is right for you, consider the nature of your material and your final objective.

- If your primary focus is processing heat-sensitive materials: Cold grinding is the superior choice to preserve their essential chemical and physical characteristics.

- If your primary focus is achieving an ultra-fine, free-flowing powder from a soft or elastic material: The embrittlement from cold grinding is the most effective way to enable a clean fracture.

- If your primary focus is high-purity material separation: This process is unmatched for cleanly liberating components, like separating rubber from embedded steel fibers.

- If your primary focus is low-cost bulk reduction of a durable material: Traditional ambient grinding remains the most economical solution.

Ultimately, cold grinding is a precision tool applied when the cost of compromising material quality is higher than the cost of the process itself.

Summary Table:

| Key Aspect | Cold Grinding | Traditional Grinding |

|---|---|---|

| Temperature | Extremely low (cryogenic) | Ambient or elevated |

| Heat Generation | Minimal | Significant |

| Material Suitability | Ideal for heat-sensitive materials (plastics, spices, pharmaceuticals) | Best for durable materials (stone, ore) |

| Particle Quality | Fine, uniform, preserves chemical integrity | Risk of melting, smearing, or degradation |

| Cost & Complexity | Higher (requires liquid nitrogen, specialized equipment) | Lower and simpler |

Ready to Preserve Your Material's Integrity with Precision Cold Grinding?

If you work with heat-sensitive materials like polymers, spices, pharmaceuticals, or need high-purity separation, KINTEK's advanced cold grinding solutions are designed for you. Our specialized lab equipment ensures your products maintain their essential properties and achieve superior particle quality.

Contact our experts today to discuss how our cold grinding systems can enhance your laboratory processes and deliver the high-purity results you demand.

Visual Guide

Related Products

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Powerful Plastic Crusher Machine

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

People Also Ask

- What is the role of a cryogenic grinder in PET recycling? Transform Waste into High-Reactive Micron Powders

- What is the mechanism of a cryogenic grinder? Master Polymer Powder Preparation for Additive Manufacturing

- What is the temperature of cryogenic grinding? Achieve Superior Particle Size & Preserve Heat-Sensitive Materials

- What is cryogenic machining used for? Process Unmachinable Materials with Extreme Cold

- What are cryogenic ground spices? Unlock Maximum Flavor with Advanced Grinding Technology