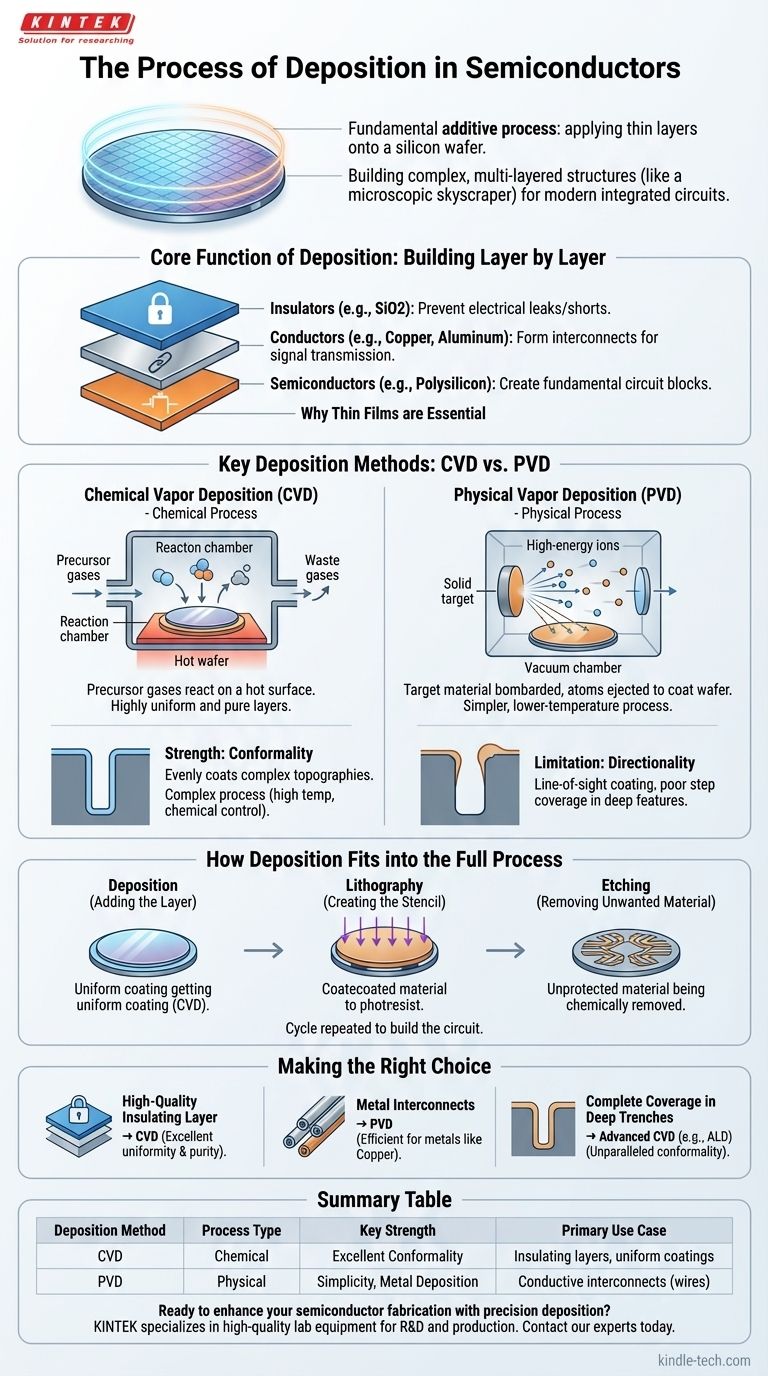

In semiconductor manufacturing, deposition is the fundamental process of applying thin layers of material onto a silicon wafer. This is a purely additive process, where materials like insulators, conductors, or semiconductors are grown or coated onto the wafer's surface, often just a few atomic layers at a time. It is the primary method for building the intricate, multi-layered structures that form modern integrated circuits.

The critical concept to understand is that deposition is about adding a uniform layer of material to a wafer. This is distinct from photolithography (patterning the layer) and etching (selectively removing parts of the layer), which are separate, subsequent steps in the fabrication sequence.

The Core Function of Deposition

Building the Circuit, Layer by Layer

Think of a microprocessor as a microscopic, multi-story skyscraper. Deposition is the process of adding each new floor (an insulating layer) or the wiring within the walls (a conductive layer).

This process is repeated hundreds of times to build the complex vertical structure of a modern chip. The quality and precision of each deposited layer are paramount to the final device's performance.

Why Thin Films are Essential

The thin films created by deposition serve specific, critical functions:

- Insulators (e.g., silicon dioxide, silicon nitride) prevent electrical currents from leaking or shorting out between different components.

- Conductors (e.g., copper, aluminum, tungsten) form the microscopic wires, or "interconnects," that transmit signals between transistors.

- Semiconductors (e.g., polysilicon) are used to create the fundamental building blocks of the circuit, such as the transistor gates.

Key Deposition Methods: CVD vs. PVD

While there are many specific techniques, nearly all deposition processes fall into two main families: Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD).

Chemical Vapor Deposition (CVD)

CVD is a chemical process. Precursor gases are introduced into a reaction chamber containing the heated wafer.

These gases react on the hot surface, leaving behind a solid thin film of the desired material and releasing other gaseous byproducts, which are then vented. This method is known for producing highly uniform and pure layers.

Physical Vapor Deposition (PVD)

PVD is a physical process, often compared to atomic-level spray painting. Inside a vacuum chamber, a solid source material (called a "target") is bombarded with high-energy ions.

This bombardment knocks atoms loose from the target. These atoms then travel through the vacuum and coat the wafer, building up the thin film atom by atom.

Understanding the Trade-offs

The choice between CVD and PVD is dictated by the material being deposited and the structural requirements of the layer.

CVD: Conformality vs. Complexity

CVD's strength is its conformality. Because the chemical reaction happens everywhere on the surface, it can evenly coat the bottom and sides of very deep, narrow trenches in the wafer's topography.

The trade-off is complexity. CVD often requires high temperatures and involves volatile chemical reactions that must be precisely controlled to ensure layer purity and prevent defects.

PVD: Simplicity vs. Directionality

PVD is often a simpler, lower-temperature process, which is ideal for depositing metals that can't withstand the high heat of CVD.

Its primary limitation is directionality. Because the atoms travel in a "line-of-sight" from the target to the wafer, PVD can struggle to evenly coat the sidewalls of deep features, a problem known as poor "step coverage."

How Deposition Fits into the Full Process

The steps described in some manufacturing guides can be confusing. Deposition is only the first part of a three-step cycle that is repeated over and over.

Step 1: Deposition (Adding the Layer)

A uniform layer of material, such as silicon nitride, is deposited across the entire surface of the wafer using a method like CVD.

Step 2: Lithography (Creating the Stencil)

A light-sensitive material called photoresist is coated on top of the deposited layer. It is then exposed to UV light through a patterned mask, and the pattern is developed, creating a protective stencil.

Step 3: Etching (Removing Unwanted Material)

A chemical or plasma etching process removes the silicon nitride in the areas not protected by the photoresist stencil. Finally, the remaining photoresist is stripped away, leaving behind the desired circuit pattern.

Making the Right Choice for Your Goal

The choice between deposition methods is dictated entirely by the specific layer's function within the integrated circuit.

- If your primary focus is creating a high-quality insulating layer (e.g., a transistor gate oxide): Chemical Vapor Deposition (CVD) is the preferred method for its excellent uniformity and purity.

- If your primary focus is creating the metal interconnects (wires): Physical Vapor Deposition (PVD) is commonly used for its efficiency in depositing metals like copper or aluminum.

- If your primary focus is ensuring complete coverage in deep, narrow trenches: Advanced techniques like Atomic Layer Deposition (ALD), a precise sub-type of CVD, are required for their unparalleled conformality.

Ultimately, mastering deposition is about selecting the right additive technique to precisely build the foundation for each subsequent patterning and etching step.

Summary Table:

| Deposition Method | Process Type | Key Strength | Primary Use Case |

|---|---|---|---|

| Chemical Vapor Deposition (CVD) | Chemical | Excellent Conformality | Insulating layers, uniform coatings |

| Physical Vapor Deposition (PVD) | Physical | Simplicity, Metal Deposition | Conductive interconnects (wires) |

Ready to enhance your semiconductor fabrication process with precision deposition? KINTEK specializes in high-quality lab equipment and consumables for semiconductor R&D and production. Whether you require CVD systems for uniform insulating layers or PVD tools for reliable metal interconnects, our solutions are designed to meet the stringent demands of modern chip manufacturing. Contact our experts today to discuss how we can support your laboratory's specific deposition needs and help you build better integrated circuits.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production