At its core, extrusion blow molding is a manufacturing process that creates hollow plastic parts by forming a tube of molten plastic and then using compressed air to inflate it against the inside of a mold. This simple and efficient technique is responsible for producing countless common items, from bottles and jugs to automotive ducts and tanks.

The process fundamentally transforms a simple, extruded tube of molten plastic—called a parison—into a finished, hollow product. This is achieved by capturing the parison inside a mold and using air pressure to shape it, much like blowing up a balloon.

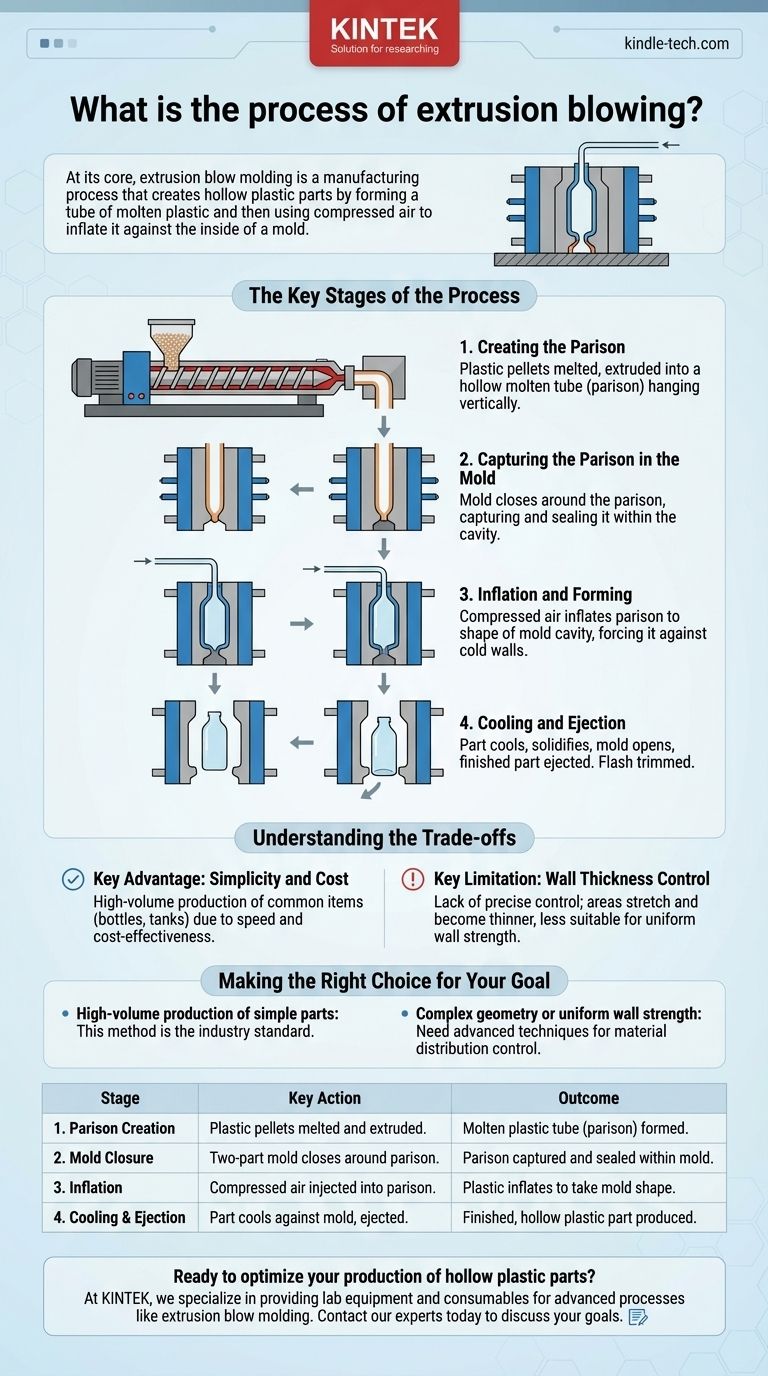

The Key Stages of the Process

The entire operation can be broken down into a few distinct, sequential stages. Each step is critical for transforming raw plastic resin into a durable, hollow part.

Step 1: Creating the Parison

The process begins with the extruder. This machine takes solid plastic pellets, heats them until they are molten, and then forces the liquid plastic through a shaping tool called a die.

This action forms a continuous, hollow tube of hot plastic known as the parison, which hangs vertically from the die.

Step 2: Capturing the Parison in the Mold

A two-part, water-cooled mold is positioned around the hanging parison. The mold is shaped with a cavity that matches the exact external dimensions of the final desired product.

Once the parison has been extruded to the correct length, the two halves of the mold quickly close around it. This action pinches the bottom of the parison shut and captures the tube within the mold cavity.

Step 3: Inflation and Forming

With the mold securely closed, compressed air is injected into the top of the parison, often through a pin at the neck of the container.

This burst of air pressure inflates the soft, molten plastic tube, forcing it outwards until it presses firmly against the cold interior walls of the mold. The plastic takes on the precise shape of the mold cavity.

Step 4: Cooling and Ejection

The plastic is held against the water-cooled mold for a short period. The contact with the cold surface rapidly solidifies the material, locking it into its new shape.

After the part has cooled sufficiently, the mold opens, and the finished, hollow product is ejected. Any excess plastic, known as "flash," is then trimmed off.

Understanding the Trade-offs

Like any manufacturing process, extrusion blow molding has inherent strengths and limitations that make it suitable for specific applications.

Key Advantage: Simplicity and Cost

The primary advantage of this method is its relative simplicity and economic efficiency. The machinery is less complex than other blow molding variants, making it ideal for high-volume production of common items like bottles and containers.

Key Limitation: Wall Thickness Control

The main trade-off is a lack of precise control over the material's wall thickness. As the simple parison tube stretches to fill a complex mold shape, some areas will become thinner than others. This makes it less suitable for parts that require perfectly uniform wall strength.

Making the Right Choice for Your Goal

Understanding the core mechanism helps determine when this process is the best fit for a project.

- If your primary focus is high-volume production of simple hollow parts: This method is the industry standard for items like milk jugs, shampoo bottles, and chemical tanks due to its speed and cost-effectiveness.

- If your primary focus is creating parts with highly complex geometry or requiring uniform wall strength: You may need to explore more advanced molding techniques that offer greater control over material distribution during the inflation stage.

Ultimately, extrusion blow molding is a foundational technology that expertly balances simplicity and function to create the hollow plastic goods we use every day.

Summary Table:

| Stage | Key Action | Outcome |

|---|---|---|

| 1. Parison Creation | Plastic pellets are melted and extruded into a hollow tube. | A molten plastic tube (parison) is formed. |

| 2. Mold Closure | A two-part mold closes around the parison. | The parison is captured and sealed within the mold. |

| 3. Inflation | Compressed air is injected into the parison. | The plastic inflates to take the shape of the mold cavity. |

| 4. Cooling & Ejection | The part cools against the water-cooled mold and is ejected. | A finished, hollow plastic part is produced. |

Ready to optimize your production of hollow plastic parts?

At KINTEK, we specialize in providing the lab equipment and consumables that support advanced manufacturing processes like extrusion blow molding. Whether you are in R&D, quality control, or scaling up production, our solutions help you achieve greater efficiency and consistency.

Contact our experts today to discuss how we can support your laboratory and production goals with precision equipment and expert guidance.

Visual Guide

Related Products

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Small Injection Molding Machine for Lab Use

- Powerful Plastic Crusher Machine

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is a vulcanizing press? Essential Tool for Rubber Manufacturing and Tire Production

- How many types of rolling mills are there? A Guide to Roll Configurations & Capabilities

- What are extruded examples? Discover the Process Behind Everyday Objects

- What is the difference between extrusion coating and extrusion lamination? A Guide to Material Enhancement

- What is a two roll mill for rubber compounding? A Foundational Tool for Polymer Processing

- What is pyrolysis of rubber? Transform Waste Tires into Oil, Carbon & Gas

- What is the process of multilayer extrusion? Engineer High-Performance Plastic Films

- What are the two common types of injection molding processes? Thermoplastic vs. Thermoset Explained