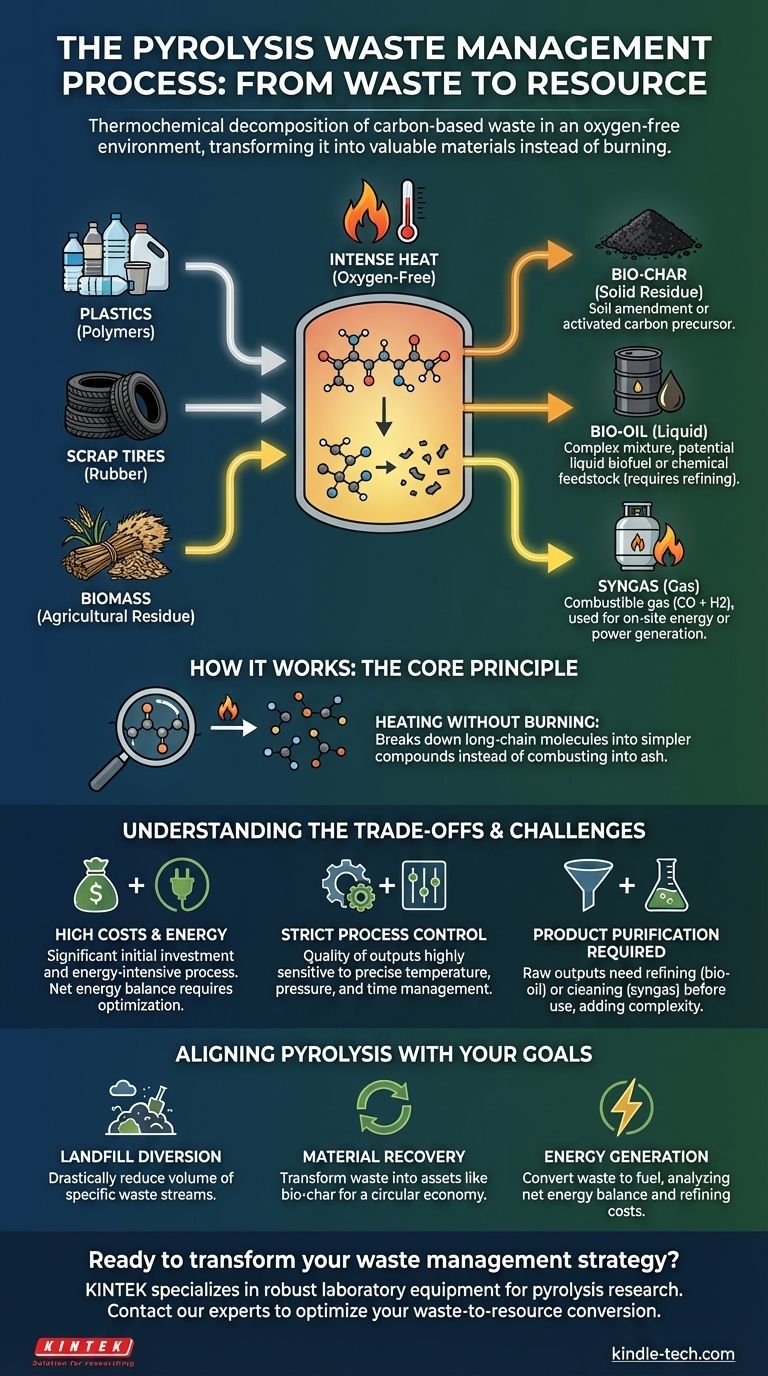

At its core, pyrolysis is a thermochemical process for waste management that uses intense heat to break down materials in an oxygen-free environment. Unlike incineration, which burns waste, pyrolysis causes materials like plastics, tires, and biomass to decompose into a solid residue (bio-char), a liquid (bio-oil), and a gas (syngas), transforming waste into potentially valuable resources.

Pyrolysis should be understood not as simple waste disposal, but as a resource recovery technology. It shifts the paradigm from burying a problem to deconstructing it into valuable components, though this transformation comes with significant technical and economic challenges.

How Pyrolitic Decomposition Works

Pyrolysis fundamentally alters the chemical structure of waste. By heating materials to high temperatures without the oxygen needed for combustion, it avoids burning and instead forces a controlled thermal breakdown.

The Core Principle: Heating Without Burning

The absence of oxygen is the critical factor. Without it, the long-chain polymer molecules in materials like plastic or rubber don't combust into ash and flue gas. Instead, the intense heat breaks them down into smaller, simpler, and often more valuable molecules.

Acceptable Inputs: Carbon-Based Waste

The process is most effective on materials rich in carbon. Common feedstocks include:

- Plastics: Converting polymer waste into liquid fuels or chemical feedstocks.

- Scrap Tires: Breaking down rubber into carbon black (a form of bio-char), oil, and gas.

- Biomass: Transforming agricultural or forestry residue into biofuels and soil amendments.

The Three Primary Outputs

The decomposition process consistently yields three distinct product streams, each with its own potential use.

Bio-char (The Solid)

This stable, carbon-rich solid is similar to charcoal. It can be used as a soil amendment to improve fertility and water retention or serve as a raw material for producing high-grade activated carbon.

Bio-oil (The Liquid)

Also known as pyrolysis oil, this is a complex liquid mixture of organic compounds. After significant refining, it has the potential to be used as a liquid biofuel or a chemical feedstock.

Syngas (The Gas)

This mixture of combustible gases, primarily carbon monoxide and hydrogen, can be burned on-site. Its most common use is to provide the energy needed to fuel the pyrolysis process itself, creating a more self-sustaining system.

Understanding the Trade-offs

While promising, pyrolysis is not a universal solution. Its practical application involves clear and significant challenges that must be weighed against its benefits.

High Capital and Energy Costs

Pyrolysis plants require a substantial initial investment. Furthermore, the process is highly energy-intensive, and while the syngas produced can offset some energy consumption, it often remains a net energy drain without careful optimization.

Strict Process Control is Required

The quality and proportion of the three outputs (char, oil, gas) are highly sensitive to process conditions. Maintaining the precise temperature, pressure, and processing time required for an efficient and consistent outcome is a complex operational challenge.

Product Purification is Essential

The raw outputs of pyrolysis are not immediately usable. The bio-oil must be refined to be used as fuel, and the syngas often needs to be cleaned. These post-processing steps add complexity and cost to the overall operation.

Making the Right Choice for Your Goal

Implementing pyrolysis effectively depends entirely on aligning the technology's strengths with a clear strategic objective.

- If your primary focus is landfill diversion: Pyrolysis is an excellent tool for drastically reducing the volume of specific, homogenous waste streams like tires or certain plastics.

- If your primary focus is creating valuable materials: The technology excels at transforming waste into assets like bio-char for agriculture or industry, supporting a circular economy model.

- If your primary focus is energy generation: Pyrolysis offers a pathway to convert waste into fuel, but you must carefully analyze the net energy balance and the high cost of refining the outputs.

Ultimately, understanding pyrolysis as a sophisticated material transformation process, rather than a simple disposal method, is the key to unlocking its potential.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Thermochemical decomposition of waste in an oxygen-free environment. |

| Primary Inputs | Carbon-based materials like plastics, tires, and biomass. |

| Primary Outputs | Bio-char (solid), Bio-oil (liquid), and Syngas (gas). |

| Key Benefit | Transforms waste into valuable resources, supporting a circular economy. |

| Main Challenge | High capital costs and the need for strict process control and product purification. |

Ready to transform your waste management strategy with advanced pyrolysis technology?

KINTEK specializes in providing robust laboratory equipment and consumables to support your research and development in pyrolysis processes. Whether you are testing feedstock viability, optimizing output yields, or analyzing the quality of bio-oil and bio-char, our precise and reliable tools are designed to meet the rigorous demands of your lab.

Contact our experts today via our contact form to discover how KINTEK's solutions can help you achieve efficient and effective waste-to-resource conversion.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs