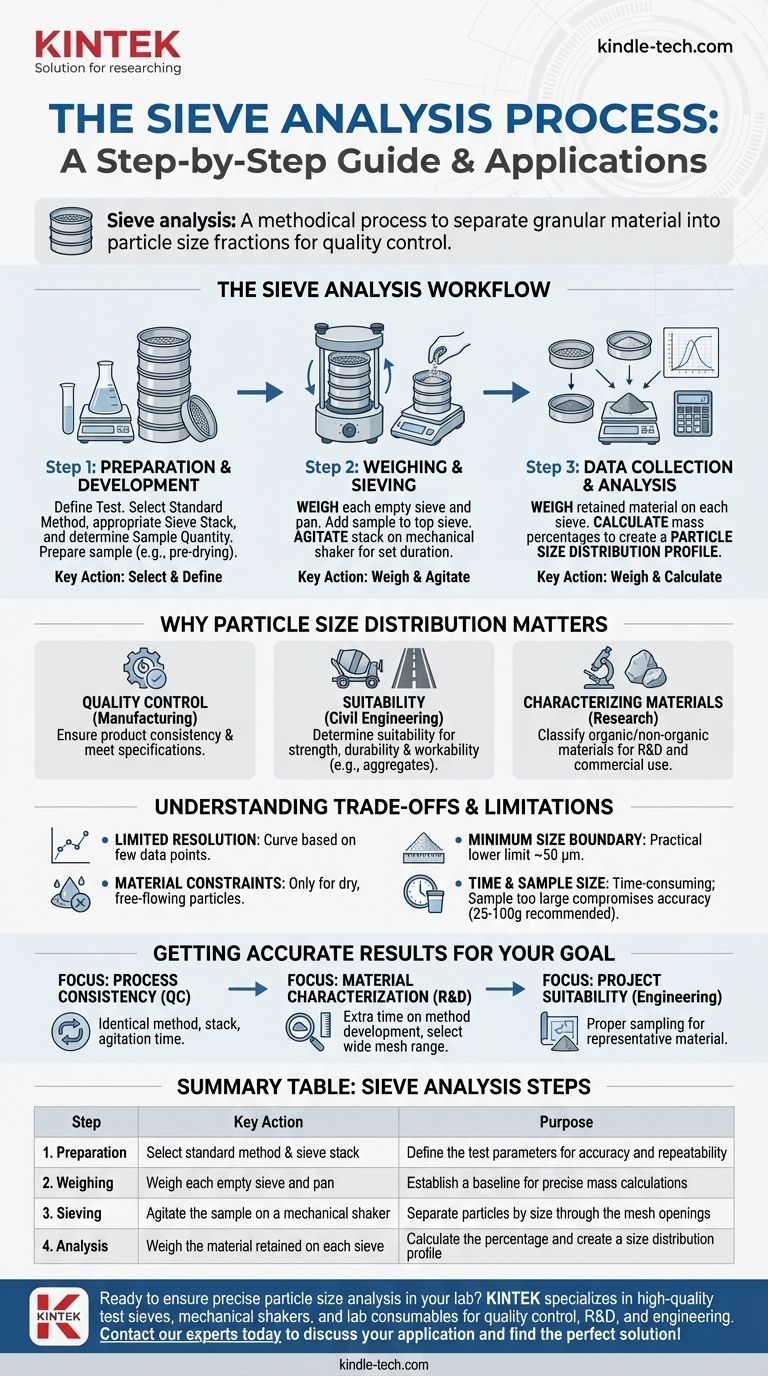

At its core, sieve analysis is a methodical process for separating a granular material into different particle size fractions. The procedure involves preparing a representative sample, weighing a stack of sieves with progressively smaller mesh openings, adding the sample to the top sieve, agitating the stack, and then weighing the material retained on each individual sieve to determine the particle size distribution.

Sieve analysis is a foundational quality control technique used to determine the particle size distribution of granular materials. Its reliability, however, is not in the shaking itself, but in the meticulous adherence to a standardized procedure from sample preparation to final data analysis.

Why Particle Size Distribution Matters

Sieve analysis provides critical data that informs decisions across various industries. It's not just about sorting particles; it's about ensuring materials meet precise specifications for performance and safety.

Quality Control in Manufacturing

For manufacturers of powdered or granular products, consistency is key. Sieve analysis serves as a direct quality control check, providing insight into the particle size range throughout a production line and ensuring the final product meets customer requirements.

Suitability in Civil Engineering

The properties of materials like concrete and asphalt are directly tied to the size and grading of the aggregates used. Sieve analysis determines if sand or crushed rock is suitable for a specific mix, impacting the strength, durability, and workability of the final structure.

Characterizing Raw Materials

This technique is used to classify a wide range of organic and non-organic materials. This includes sand, clay, granite, coal, soil, and even grains and seeds, providing a fundamental physical property for research, development, and commercial use.

The Sieve Analysis Workflow: A Step-by-Step Guide

A successful analysis depends on a precise and repeatable workflow. Each step builds upon the last, and errors in the early stages will compromise the final results.

Step 1: Preparation and Method Development

Before any material is measured, the test itself must be defined. This involves selecting a suitable standard method based on the material being tested.

You must then select the appropriate stack of test sieves, ensuring the mesh sizes cover the expected particle range. The required sample quantity is also determined, and the sample itself is prepared through processes like pre-drying or conditioning.

Step 2: Weighing and Sieving

Accuracy begins with precise measurements. The first action is to weigh each empty sieve and the bottom pan, carefully recording each weight.

The prepared material sample is then added to the top sieve of the assembled stack. The entire stack is then agitated, either manually or, more commonly, with a mechanical sieve shaker for a set duration to ensure particles have an opportunity to pass through the apertures.

Step 3: Data Collection and Analysis

After agitation is complete, the stack is disassembled. Each sieve is weighed again, this time with the fraction of material it retained.

By subtracting the empty sieve weight from the final weight, you determine the mass of particles on each sieve. This data is used to calculate the percentage of material retained at each size level, creating a particle size distribution profile.

Understanding the Trade-offs and Limitations

While widely used, sieve analysis is not without its constraints. Understanding these is crucial for interpreting results correctly.

Limited Resolution

A standard sieve stack typically contains a maximum of eight sieves. This means the resulting particle size distribution curve is based on just a few data points, which may not capture the full detail of a material's grading.

Material Constraints

The method is fundamentally based on gravity and agitation, meaning it only works with dry, free-flowing particles. Materials that are wet, sticky, or clump together will not produce an accurate result.

Minimum Size Boundary

There is a practical lower limit to the particle size that can be effectively measured. For standard woven-wire sieves, this is typically around 50 micrometers (µm). Finer particles require different analysis techniques.

Time and Sample Size

The process can be time-consuming, especially when including sample drying time. Furthermore, using a sample that is too large can compromise accuracy, as individual particles may not get a chance to reach the correct sieve screen. A sample of 25-100 grams is typically recommended.

Getting Accurate Results for Your Goal

The right approach to sieve analysis depends on your ultimate objective. Following the correct procedure is non-negotiable, but your focus may shift based on the desired outcome.

- If your primary focus is process consistency (QC): Ensure every test uses the identical standardized method, sieve stack, and agitation time to guarantee repeatable and comparable results.

- If your primary focus is material characterization (R&D): Spend extra time on method development, selecting a range of sieve mesh sizes that will best capture the unique distribution of your specific material.

- If your primary focus is project suitability (Engineering): Pay close attention to proper sampling and sample reduction techniques to ensure the material tested is truly representative of the entire source pile or batch.

Mastering this fundamental process empowers you to validate material quality and predict its performance with confidence.

Summary Table:

| Sieve Analysis Step | Key Action | Purpose |

|---|---|---|

| 1. Preparation | Select standard method & sieve stack | Define the test parameters for accuracy and repeatability |

| 2. Weighing | Weigh each empty sieve and pan | Establish a baseline for precise mass calculations |

| 3. Sieving | Agitate the sample on a mechanical shaker | Separate particles by size through the mesh openings |

| 4. Analysis | Weigh the material retained on each sieve | Calculate the percentage and create a size distribution profile |

Ready to ensure precise particle size analysis in your lab? The accuracy of your sieve analysis depends on reliable equipment and consistent methodology. KINTEK specializes in high-quality test sieves, mechanical sieve shakers, and lab consumables designed for durability and precise results. Whether your focus is quality control, R&D, or engineering, our products help you achieve the material characterization you need.

Contact our experts today to discuss your specific application and find the perfect sieve analysis solution for your laboratory.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What type of materials can be separated using the method of sieving? A Guide to Efficient Particle Size Separation

- What are standard sieves in pharmaceutical? Precision Instruments for Particle Size Control

- Why must standard test sieves be used to screen silicon nitride ceramic powder? Ensure Uniformity and Strength

- Why must Al2O3/ZrO2 ceramic powders undergo treatment with a standard sieve? Ensuring High-Density Sintering Results

- What are the 4 methods of determining particle size? Choose the Right Technique for Your Lab

- How is a test sieve calibrated? Ensure Accurate Particle Size Analysis with Proper Verification

- Are different sieves used to separate different mixtures? Choose the Right Sieve for Your Mixture

- How are sieve sizes determined? Understanding ASTM & ISO Standards for Accurate Particle Analysis