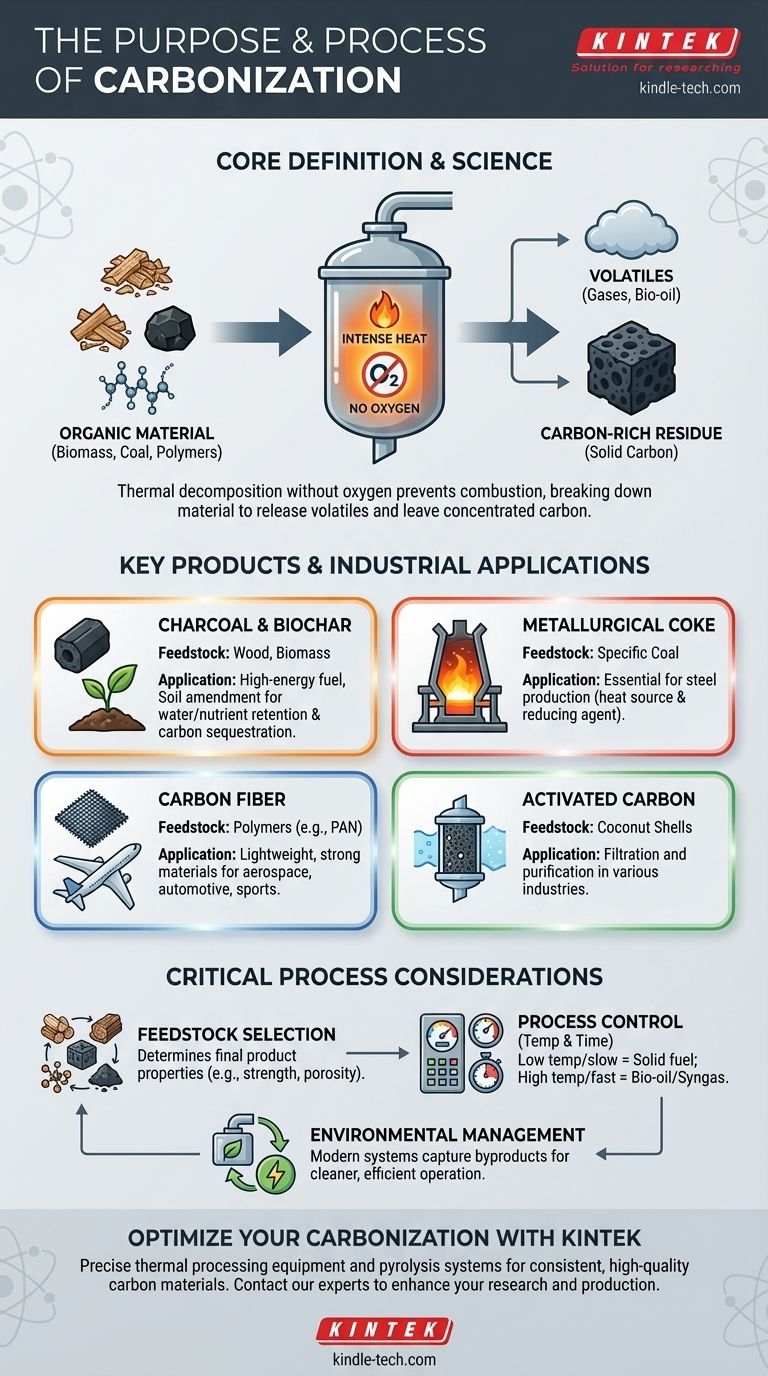

At its core, carbonization is a process of thermal decomposition used to convert organic substances into carbon or a carbon-rich residue. This is achieved by heating the material to a high temperature in the complete or near-total absence of oxygen. This crucial lack of oxygen prevents the material from combusting (burning), forcing its chemical structure to break down and release volatile compounds, leaving behind a solid, concentrated form of carbon.

The fundamental purpose of carbonization is not to destroy a material with heat, but to transform it. By carefully controlling high temperatures without oxygen, we can create valuable, carbon-rich products like charcoal, coke, and carbon fiber from less-refined organic matter.

The Science of Transformation: How Carbonization Works

Carbonization is a controlled chemical reaction, not a simple act of burning. The process hinges on two critical factors: intense heat and an oxygen-starved environment.

The Role of High Temperature

Heat provides the necessary energy to break the complex chemical bonds within organic materials like wood, coal, or polymers. As temperatures rise, these materials become unstable.

The Critical Absence of Oxygen

If oxygen were present, the material would simply burn, a process called combustion, releasing its energy as heat and light and producing ash. By removing oxygen, we prevent combustion and force a different chemical pathway.

The Chemical Transformation

Without oxygen to react with, the heating process drives off volatile components like water, methane, hydrogen, and various oils (often called tar or bio-oil). What remains is a solid, porous, and highly concentrated carbon material. The specific properties of this final product are determined by the starting material and the process conditions.

Key Products and Their Industrial Purpose

The true purpose of carbonization is realized in its valuable end products, which are foundational to numerous industries.

Charcoal and Biochar

When wood or other biomass is carbonized, the result is charcoal. This has been used for centuries as a high-energy, low-smoke fuel.

When the goal is agricultural, the product is called biochar. This porous material is added to soil to dramatically improve water retention, nutrient availability, and microbial health, while also sequestering carbon from the atmosphere.

Metallurgical Coke

Carbonizing specific types of coal produces metallurgical coke, a material that is absolutely essential for primary steel production. In a blast furnace, coke serves two purposes: it provides the intense heat needed to melt iron ore and acts as a chemical reducing agent, removing oxygen from the ore to produce pure liquid iron.

Carbon Fiber

In high-technology applications, polymers like polyacrylonitrile (PAN) are carbonized to create carbon fiber. This process meticulously removes all non-carbon elements, leaving behind long, perfectly aligned chains of carbon atoms. The result is a material that is exceptionally strong, stiff, and lightweight, making it vital for the aerospace, automotive, and high-performance sports industries.

Understanding the Trade-offs and Considerations

Achieving the desired outcome from carbonization requires a deep understanding of its variables and limitations. The process is precise, and small changes can lead to vastly different products.

Feedstock Determines the Outcome

The starting material, or feedstock, is the single most important factor. Carbonizing coconut shells produces excellent activated carbon for filters, while carbonizing specific coals is the only way to produce the strong coke needed for steelmaking. The final product is always a reflection of its origin.

Process Control is Crucial

The final temperature, the rate of heating, and the time spent at that temperature are critical control parameters.

- Slow, lower-temperature carbonization (torrefaction) yields a product that retains more mass and is suitable for solid fuel.

- Fast, higher-temperature carbonization (fast pyrolysis) maximizes the production of liquid and gaseous byproducts (bio-oil and syngas), which can be used as biofuels.

Environmental Impact and Management

Carbonization releases volatile gases. If not properly managed, these can include methane and carbon monoxide, which are greenhouse gases or pollutants. Modern industrial carbonization plants, however, often capture these byproducts. The syngas can be burned to power the process itself, creating a more efficient and cleaner system.

Making the Right Choice for Your Goal

The application of carbonization should be dictated by your specific objective. The process is a tool, and its value lies in creating a specific product.

- If your primary focus is sustainable agriculture or carbon sequestration: Your goal is to produce biochar from waste biomass using controlled pyrolysis to maximize solid yield and soil benefits.

- If your primary focus is heavy industry and steel production: You must use high-grade coking coal to produce metallurgical coke with the specific strength and chemical properties required for a blast furnace.

- If your primary focus is creating advanced lightweight materials: You will be carbonizing polymer precursors under highly controlled tension and atmospheric conditions to manufacture high-performance carbon fiber.

- If your primary focus is renewable energy: You can use fast pyrolysis on biomass to maximize the output of bio-oil and syngas, which can then be used to generate electricity or heat.

By precisely controlling heat in an oxygen-free environment, carbonization transforms common organic materials into highly specialized and valuable forms of carbon.

Summary Table:

| Product | Feedstock | Key Application |

|---|---|---|

| Charcoal/Biochar | Wood, Biomass | Fuel, Soil Amendment |

| Metallurgical Coke | Specific Coal | Steel Production |

| Carbon Fiber | Polymers (e.g., PAN) | Aerospace, Automotive |

| Activated Carbon | Coconut Shells | Filtration, Purification |

Need precise thermal processing equipment for your carbonization projects? KINTEK specializes in high-performance lab furnaces and pyrolysis systems that deliver the exact temperature control and oxygen-free environments required to produce consistent, high-quality carbon materials. Whether you're developing biochar for agriculture, coke for metallurgy, or carbon fiber for advanced composites, our expertise in lab equipment can help you optimize your process. Contact our experts today to discuss how KINTEK's solutions can enhance your research and production outcomes.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- What is the graphite furnace technique? Achieve Extreme Temperatures for Advanced Materials

- What is the role of an industrial graphitization furnace in SiC/MoSi2 coatings? Enhance Substrate Protection

- What is a carbonization furnace? Transform Waste Biomass into Valuable Charcoal Efficiently

- What is the temperature of atomic absorption in graphite furnace? Mastering the Multi-Stage Heating Program

- What is the process of isostatic graphite? A Guide to High-Performance, Uniform Material Creation

- Why is a graphite furnace rather than a flame often used for atomization? Superior Sensitivity for Trace Analysis

- What is isostatic graphite? The Ultimate Material for High-Tech and High-Temperature Applications

- How do you carbonize charcoal? Master the 3-Step Pyrolysis Process for High-Purity Carbon