At its core, Physical Vapor Deposition (PVD) is an advanced coating process used to apply an extremely thin but highly durable film onto a material's surface. Conducted in a vacuum, PVD enhances an object's properties by improving its hardness, wear resistance, and corrosion resistance, or by applying a high-quality decorative finish.

PVD is not a single technique but a family of vacuum-based processes designed to engineer a material's surface properties on an atomic level. Its purpose is to grant a base material new characteristics—like superior strength or a specific color—without altering its underlying structure.

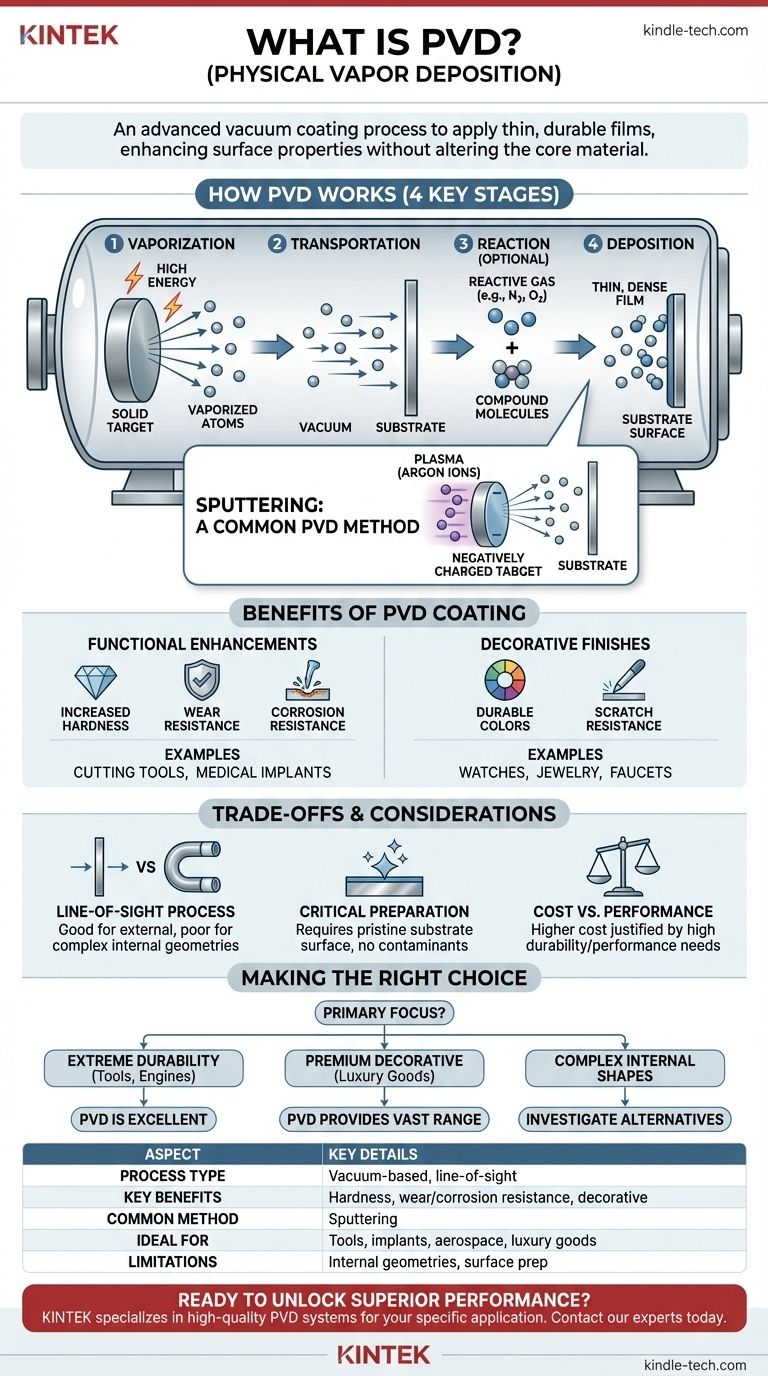

How PVD Fundamentally Works

Physical Vapor Deposition is a line-of-sight process that involves four key stages. The entire process takes place inside a high-vacuum chamber to ensure the purity and quality of the coating.

Stage 1: Vaporization

The process begins with a solid source material, known as the target. This target is bombarded with high energy, causing it to release individual atoms or molecules. This turns the solid material into a vapor.

Stage 2: Transportation

These vaporized atoms travel through the vacuum chamber from the target toward the object being coated, which is called the substrate. The vacuum is critical because it prevents these atoms from colliding with air or other particles, ensuring a clean path.

Stage 3: Reaction (Optional)

In some cases, a reactive gas like nitrogen or oxygen is introduced into the chamber. The vaporized atoms from the target react with this gas mid-flight to form a new compound, which will become the final coating. This is known as reactive PVD.

Stage 4: Deposition

The vaporized atoms (or newly formed compound molecules) land on the substrate and condense back into a solid state. They build up layer by layer, forming a thin, dense, and highly-adherent film on the object's surface.

Sputtering: A Common PVD Method

While there are several ways to vaporize the target material, one of the most common and economical methods is sputtering.

The Sputtering Mechanism

In sputtering, a high-voltage electrical field is used to create a plasma from an inert gas, typically argon. The positively charged argon ions are accelerated with immense force, striking the negatively charged target.

This high-energy bombardment physically knocks atoms off the target material, "sputtering" them into the vacuum chamber, where they then travel to the substrate for deposition.

Why Sputtering is Widely Used

Sputtering is valued for its versatility and control. It allows for the deposition of a vast range of materials—including metals, alloys, and ceramics—onto many different types of substrates, making it a standard technique in numerous industries.

The Practical Benefits of a PVD Coating

The purpose of undergoing this complex process is to achieve surface properties that the base material alone cannot provide. These benefits fall into two main categories.

Functional Enhancements

For industrial applications, PVD coatings are used to drastically improve performance. Key benefits include increased hardness, reduced friction, and superior oxidation and corrosion resistance. This is critical for cutting tools, medical implants, and aerospace components.

Decorative Finishes

For consumer goods like watches, jewelry, and faucets, PVD provides a decorative finish that is far more durable than traditional methods like electroplating. It offers a wide spectrum of colors that resist fading, tarnishing, and scratching.

Understanding the Trade-offs and Considerations

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

It's a Line-of-Sight Process

Because the vaporized atoms travel in a straight line, PVD is excellent for coating external surfaces. However, it cannot easily coat complex internal geometries or the inside of a long, narrow tube.

Substrate Preparation is Critical

The substrate surface must be perfectly clean for the PVD coating to adhere properly. Any contaminants, oils, or oxides will result in a failed or poor-quality coating. This preparation adds a significant step to the manufacturing process.

Cost Versus Performance

PVD is a more complex and generally more expensive process than painting or basic electroplating. Its value is justified when the performance requirements for durability, hardness, or corrosion resistance are high and cannot be met by other means.

Making the Right Choice for Your Goal

PVD is a powerful tool for surface engineering when applied to the right problem.

- If your primary focus is extreme durability: PVD is an excellent choice for creating wear-resistant surfaces on tools, engines, and other high-performance components.

- If your primary focus is a premium decorative finish: PVD provides a vast range of stable colors with a durability that far exceeds traditional plating for luxury goods and high-end hardware.

- If your primary focus is coating complex internal shapes: You should investigate alternative technologies, as the line-of-sight nature of PVD makes it unsuitable for these applications.

Ultimately, choosing PVD is a decision to invest in a material's surface to unlock a level of performance and longevity that the bulk material alone could never achieve.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process Type | Vacuum-based, line-of-sight coating |

| Key Benefits | Increased hardness, wear/corrosion resistance, durable decorative finishes |

| Common Method | Sputtering (using plasma to vaporize a target material) |

| Ideal For | Tools, medical implants, aerospace components, luxury goods, hardware |

| Limitations | Cannot easily coat complex internal geometries; requires pristine surface preparation |

Ready to unlock superior performance and longevity for your products?

The PVD process is a precise engineering solution, and having the right equipment is crucial for success. KINTEK specializes in high-quality lab equipment, including PVD systems, to help you achieve the perfect thin-film coating for your specific application—whether for industrial durability or premium decorative finishes.

Contact our experts today to discuss how KINTEK's solutions can meet your laboratory's coating needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications