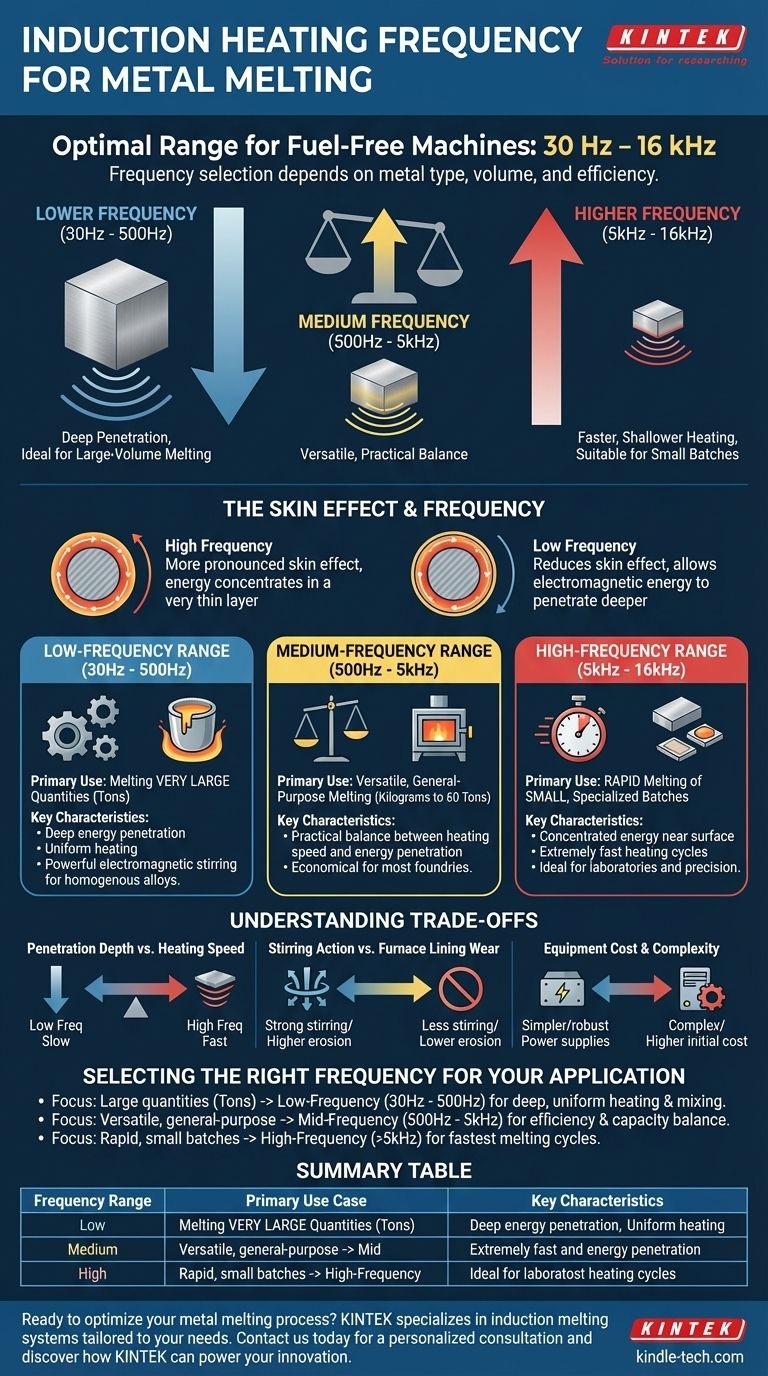

For machines designed to melt metals, the induction heating frequency can range from as low as 30 Hz to as high as 16,000 Hz (16 kHz). The specific frequency used is not arbitrary; it is carefully selected based on the type of metal, the volume being melted, and the desired efficiency of the process.

The core principle is an inverse relationship: lower frequencies penetrate deeper into the metal, making them ideal for large-volume melting, while higher frequencies provide faster, shallower heating suitable for smaller batches.

How Induction Frequency Affects Metal Melting

The choice of frequency is the most critical parameter in designing an induction melting system. It directly dictates how energy is transferred from the induction coil to the metal charge. This is governed by a principle known as the "skin effect."

The Skin Effect in Induction Heating

The skin effect describes how alternating electrical current tends to concentrate on the surface of a conductor.

A higher frequency creates a more pronounced skin effect, concentrating the heating energy in a very thin layer on the metal's surface.

A lower frequency reduces this effect, allowing the electromagnetic energy to penetrate much deeper into the metal.

Low-Frequency Range (30Hz - 500Hz)

This range is defined by its deep energy penetration. It is the standard for melting very large quantities of metal, often many tons at a time.

The deep energy transfer ensures the entire mass of the metal is heated uniformly. Furthermore, low frequencies create a powerful electromagnetic stirring action within the molten bath, which is crucial for creating homogenous alloys.

Medium-Frequency Range (500Hz - 5kHz)

Often called the "intermediate" range, this is the most versatile and common frequency band for induction furnaces. It is capable of efficiently smelting quantities from a few kilograms up to 60 tons.

This range provides a practical balance between heating speed and energy penetration, making it an economic choice for a wide variety of foundries and metal processing plants.

High-Frequency Range (5kHz - 16kHz)

High frequencies are used for applications requiring very rapid melting of smaller batches. The energy is concentrated near the surface, leading to extremely fast heating cycles.

This makes it ideal for specialized applications, laboratory settings, or processes where melting small, precise amounts of metal quickly is the primary goal.

Understanding the Trade-offs

Selecting a frequency is a matter of balancing competing technical requirements. Understanding these trade-offs is key to designing an efficient and effective system.

Penetration Depth vs. Heating Speed

The fundamental trade-off is between heating depth and speed. Deeper penetration from low frequencies is essential for large melts but is a slower process. Faster heating from high frequencies is efficient for small loads but would fail to heat the core of a large charge.

Stirring Action vs. Furnace Lining Wear

A strong stirring action, characteristic of low frequencies, is excellent for mixing alloys. However, this vigorous movement of molten metal can also accelerate the erosion of the furnace's refractory lining, increasing maintenance costs.

Equipment Cost and Complexity

Generally, power supplies for lower-frequency applications (especially those operating near mains frequency like 50/60Hz) can be simpler and more robust. High-frequency power supplies often rely on more complex solid-state electronics, which can influence the initial capital cost of the system.

Selecting the Right Frequency for Your Application

Your choice must be guided by the scale and goal of your melting operation.

- If your primary focus is melting large quantities (tons) of metal: A low-frequency system (30Hz - 500Hz) is necessary to ensure deep, uniform heating and proper alloy mixing.

- If your primary focus is versatile, general-purpose melting: The mid-frequency range (500Hz - 5kHz) offers the best overall balance of efficiency, speed, and capacity for most foundries.

- If your primary focus is rapidly melting small, specialized batches: A high-frequency furnace (above 5kHz) will provide the fastest possible melting cycles for smaller loads.

Ultimately, matching the induction frequency to the mass of the metal is the key to an efficient and controllable melting process.

Summary Table:

| Frequency Range | Primary Use Case | Key Characteristics |

|---|---|---|

| Low (30Hz - 500Hz) | Melting large quantities (tons) | Deep energy penetration, strong stirring action, uniform heating |

| Medium (500Hz - 5kHz) | Versatile, general-purpose melting | Balanced penetration and speed, efficient for most foundries |

| High (5kHz - 16kHz) | Rapid melting of small, specialized batches | Fast surface heating, ideal for labs and precise applications |

Ready to optimize your metal melting process? The right induction heating frequency is critical for efficiency, cost-effectiveness, and product quality. At KINTEK, we specialize in providing advanced lab equipment and consumables, including induction melting systems tailored to your specific needs—whether you're processing large batches or require precision for smaller loads. Our experts will help you select the ideal system to enhance your laboratory's capabilities. Contact us today for a personalized consultation and discover how KINTEK can power your innovation.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What are the advantages of an electric induction furnace? Achieve Superior Metal Melting Quality & Efficiency

- What is the process of induction furnace in steel manufacturing? Efficient, Clean Melting for Specialty Steel

- What is the temperature for induction hardening? Achieve Precise Hardness Without Compromising Part Integrity

- What is an induction heater for forging metal? A High-Speed, Flameless Heating Solution

- What is the construction of an induction furnace? A Guide to Core Components & Melting Principles

- What is the advantage of electric induction furnace compared to direct current EAF during cool start up operation? Faster, More Efficient Melting

- How to calculate induction heating power? A Guide to Accurate System Sizing

- What is the efficiency of an induction furnace? Achieve 75-95% Energy Savings with Direct Heating