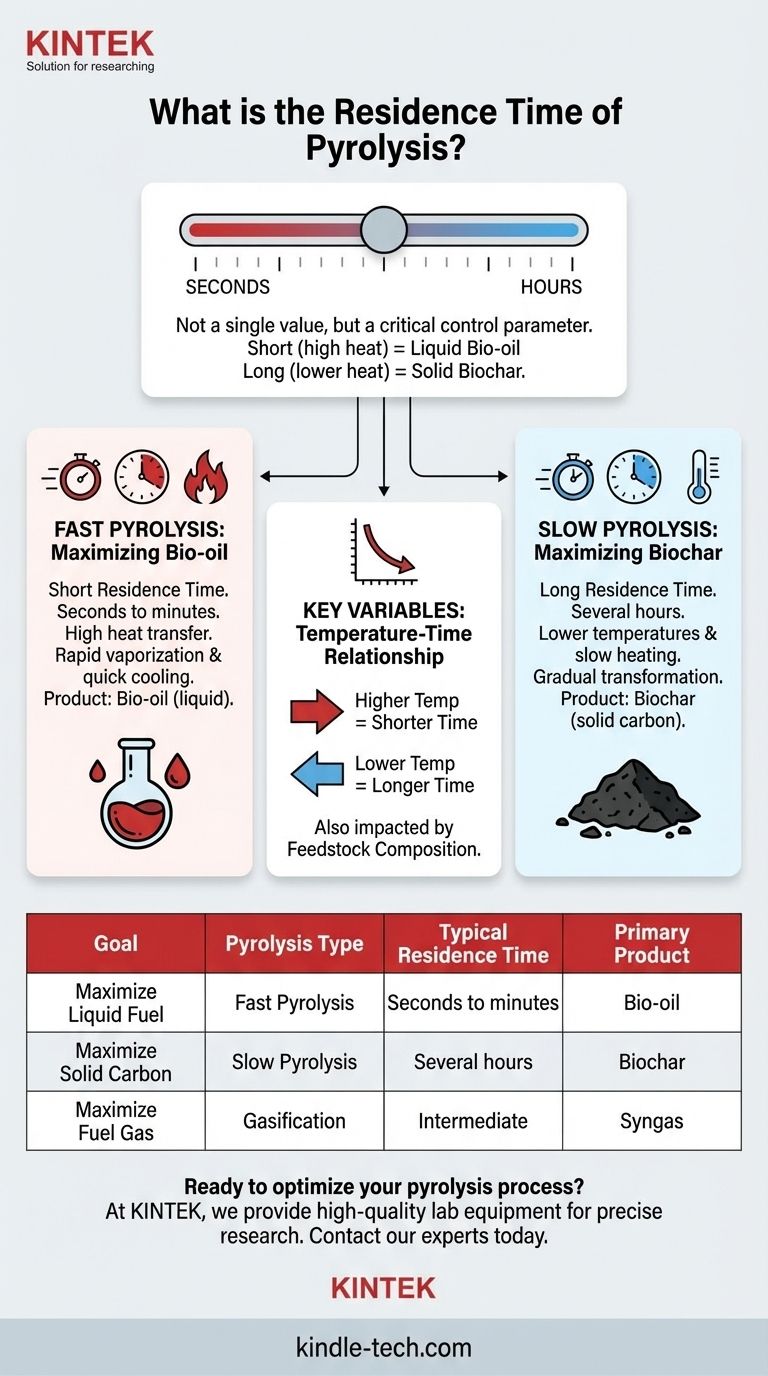

Pyrolysis residence time is not a single value but a critical control parameter that spans a vast range. Depending on the objective, the time a material spends in the reactor can be as short as a few seconds or as long as several hours. This duration, combined with temperature, directly dictates the primary end product of the process.

The core principle to understand is that residence time is a lever. A short residence time at high heat is designed to maximize liquid bio-oil, while a long residence time at lower heat is used to maximize solid biochar.

The Two Ends of the Pyrolysis Spectrum

The duration of pyrolysis is fundamentally tied to the desired chemical outcome. The process can be broadly categorized into two main types—fast and slow—each defined by its distinct residence time and temperature profile.

Fast Pyrolysis: Maximizing Bio-oil

In fast pyrolysis, the goal is to rapidly break down biomass into vapors and then quickly cool those vapors to condense them into a liquid, known as bio-oil.

This requires a very short residence time, typically from a few seconds to a few minutes. To achieve this, high heat transfer rates and high temperatures are used to ensure the material vaporizes before its chemical components can break down further into non-condensable gases or solid char.

Slow Pyrolysis: Maximizing Biochar

In slow pyrolysis, the objective is to maximize the yield of the solid carbon-rich product, biochar. This process is also known as carbonization.

This is achieved with a very long residence time, often lasting for several hours. The process uses lower temperatures and slow heating rates, allowing the biomass to gradually transform, driving off volatile components and leaving behind a stable, solid carbon structure.

Understanding the Key Variables

Residence time does not operate in a vacuum. It is part of a triangle of critical variables—time, temperature, and feedstock—that you must balance to control the outcome.

The Temperature-Time Relationship

Temperature and residence time are inversely related. Higher temperatures accelerate chemical reactions, meaning the desired conversion can be achieved in a much shorter time.

Conversely, lower temperatures slow down these reactions, requiring a longer residence time to allow the process to complete. Attempting fast pyrolysis at low temperatures would result in incomplete conversion, while performing slow pyrolysis at high temperatures would degrade the desired biochar into gas.

Impact on Product Yield

The choice between a short or long residence time is a direct trade-off between producing liquid fuel or solid carbon.

A short residence time interrupts the reaction pathway at the intermediate stage, capturing the condensable vapors as bio-oil. Extending the residence time allows these vapors to undergo secondary cracking, breaking down into lighter, non-condensable gases (syngas) and re-polymerizing into solid char.

Feedstock Considerations

The type of biomass being processed also influences the ideal residence time. Materials with different compositions of cellulose, hemicellulose, and lignin will break down at different rates, requiring slight adjustments to the time and temperature to optimize for a specific product.

Making the Right Choice for Your Goal

Selecting the correct residence time is entirely dependent on your primary objective. Use the end product to guide your process decision.

- If your primary focus is producing liquid biofuel (bio-oil): You must use fast pyrolysis, targeting a residence time measured in seconds to a few minutes.

- If your primary focus is creating a solid soil amendment or carbon sequestration product (biochar): You must use slow pyrolysis, with a residence time measured in hours.

- If your primary focus is generating fuel gas (syngas): You would typically use intermediate residence times at very high temperatures, a process more closely aligned with gasification.

Ultimately, mastering residence time is about understanding it as a tool to deliberately steer the chemical outcome of pyrolysis.

Summary Table:

| Goal | Pyrolysis Type | Typical Residence Time | Primary Product |

|---|---|---|---|

| Maximize Liquid Fuel | Fast Pyrolysis | Seconds to a few minutes | Bio-oil |

| Maximize Solid Carbon | Slow Pyrolysis | Several hours | Biochar |

| Maximize Fuel Gas | Gasification | Intermediate | Syngas |

Ready to optimize your pyrolysis process? At KINTEK, we specialize in providing high-quality lab equipment and consumables for precise pyrolysis research and development. Whether you're producing bio-oil, biochar, or syngas, our reactors and analytical tools help you accurately control residence time and temperature for maximum yield. Contact our experts today to discuss how we can support your laboratory's biomass conversion goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process