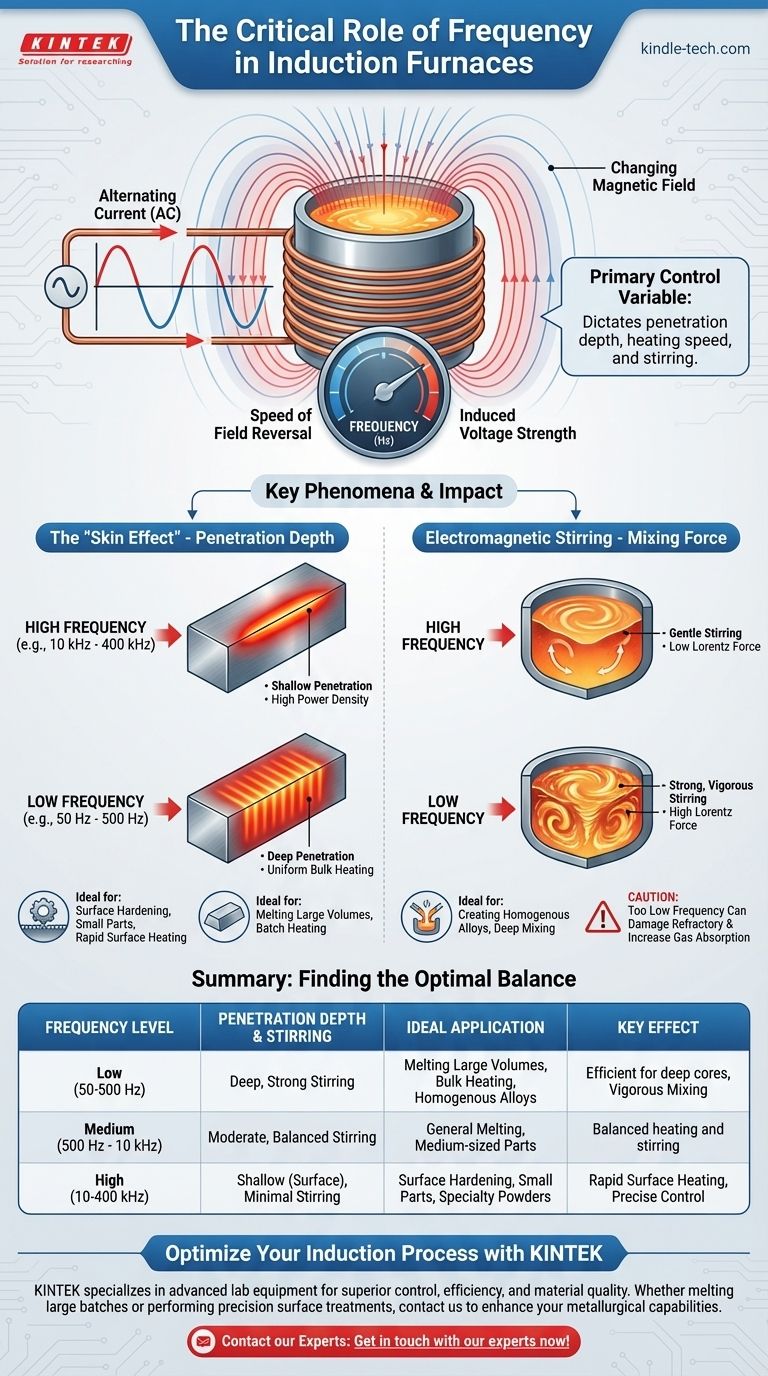

In induction heating, frequency is the primary control variable. It dictates how deeply the energy penetrates the metal, the speed of the heating process, and the degree to which the molten metal is stirred. While the alternating current itself creates the heat, the frequency of that current determines the precise nature and efficiency of the result.

Understanding the role of frequency is the key to mastering an induction furnace. It allows you to shift from simply melting metal to precisely controlling the metallurgical process, whether you need to heat the deep core of a large ingot or just the surface of a small part.

The Fundamental Principle: How Frequency Drives Induction

To understand the role of frequency, we must first look at the core mechanism of induction heating. It is a process that relies entirely on a constantly changing magnetic field.

Creating the Changing Magnetic Field

An induction furnace uses a copper coil through which a powerful alternating current (AC) is passed. This current, by its very nature, rapidly switches direction.

This oscillating current generates a powerful and rapidly fluctuating magnetic field inside the coil, where the metal to be melted (the "charge") is placed.

The Role of Frequency

The frequency is the speed at which this current and its magnetic field switch direction, measured in Hertz (Hz). A frequency of 60 Hz means the field reverses polarity 60 times per second.

Crucially, it is this change in the magnetic field that induces an electrical current within the conductive metal charge itself. According to Faraday's Law of Induction, a faster change creates a stronger induced voltage.

Inducing Heat Through Resistance

The induced electrical currents are known as eddy currents. As these currents swirl through the metal, they encounter the material's natural electrical resistance.

This resistance converts the electrical energy of the eddy currents directly into heat—a principle known as Joule heating. This is what melts the metal from the inside out.

The Critical Impact of Frequency Selection

The choice of frequency is not arbitrary; it has a direct and profound impact on how the metal heats. Two primary physical phenomena are at play: the skin effect and electromagnetic stirring.

The "Skin Effect": Controlling Penetration Depth

The most important consequence of frequency is the skin effect. This principle dictates that alternating currents tend to concentrate on the surface, or "skin," of a conductor.

Higher frequencies cause a more pronounced skin effect, forcing the eddy currents into a very thin layer at the surface. This is ideal for surface hardening or rapidly melting small-diameter parts.

Lower frequencies reduce the skin effect, allowing the magnetic field and the resulting eddy currents to penetrate much deeper into the metal. This is essential for efficiently melting large batches of material through to the core.

Power Density and Heating Speed

Because high frequencies concentrate energy on the surface, they create a very high power density in that small area. This allows for extremely rapid surface heating.

Conversely, lower frequencies distribute the energy more broadly throughout the charge's volume, resulting in a lower power density but more uniform bulk heating.

Electromagnetic Stirring

The powerful magnetic fields also exert a physical force (the Lorentz force) on the molten metal, causing it to move and circulate. This electromagnetic stirring is critical for creating homogenous alloys.

Lower frequencies produce stronger magnetic fields that penetrate deeper, resulting in a more vigorous and turbulent stirring action. Higher frequencies, concentrated at the surface, produce a much gentler stirring effect.

Understanding the Trade-offs

There is no single "best" frequency. The optimal choice always depends on a balance between the material, the size of the charge, and the desired outcome.

Efficiency vs. Application

Using a high frequency to melt a large billet of steel would be highly inefficient. You would only be heating the surface, with the core remaining cool for a long time.

Conversely, using a very low frequency on a small part would be equally inefficient, as the magnetic field might penetrate so deeply that much of its energy passes through the part without inducing sufficient current.

Stirring: A Double-Edged Sword

While stirring is vital for alloying, the powerful action from very low frequencies can be destructive. It can increase gas absorption into the melt or even accelerate the erosion of the furnace's refractory lining.

The frequency must be chosen to provide enough mixing for a homogenous final product without causing damage or introducing impurities.

Making the Right Choice for Your Goal

Selecting the correct frequency is a matter of matching the physics of induction to your specific metallurgical goal.

- If your primary focus is melting large volumes of scrap or ingots: Use a low frequency (e.g., 50 Hz to 500 Hz) to ensure deep energy penetration and thorough, uniform heating.

- If your primary focus is surface hardening or heat treating: Use a high frequency (e.g., 10 kHz to 400 kHz) to concentrate the energy precisely on the surface layer.

- If your primary focus is melting small parts or specialty powders: Use a medium-to-high frequency that matches the part size to ensure rapid and efficient energy transfer.

- If your primary focus is creating a perfectly homogenous alloy: Select a frequency low enough to induce strong stirring but high enough to avoid damaging the furnace lining.

By understanding frequency, you gain precise control over the entire induction heating and melting process.

Summary Table:

| Frequency Level | Penetration Depth | Ideal Application | Key Effect |

|---|---|---|---|

| Low (50-500 Hz) | Deep | Melting large volumes, bulk heating | Strong electromagnetic stirring |

| Medium (500 Hz - 10 kHz) | Moderate | General melting, medium-sized parts | Balanced heating and stirring |

| High (10-400 kHz) | Shallow (Surface) | Surface hardening, small parts | Rapid surface heating, minimal stirring |

Ready to optimize your induction melting process?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your specific metallurgical needs. Whether you're melting large batches or performing precision surface treatments, our expertise in induction furnace technology ensures you achieve superior control, efficiency, and material quality.

Contact us today to discuss how our solutions can enhance your laboratory's capabilities and deliver the precise results you need.

Get in touch with our experts now!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the purpose of induction furnace? Achieve Clean, Efficient Metal Melting

- What materials can be heated with induction? A Guide to Efficient Metal Heating

- What is the furnace used to melt gold? Discover the Clean, Fast Induction Method

- Does induction heating work on titanium? Mastering the Process for Aerospace & Medical Alloys

- What is the difference between high frequency and low frequency induction heating? Master the Skin Effect for Precision Results

- What are the three stages of the induction furnace lining sintering process? Master Your Furnace Longevity

- How do you melt copper with induction? A Guide to Fast, Clean, and Controlled Melting

- What is the range of induction heating? Understanding Coupling Distance and Skin Effect