In manufacturing, sintering is a thermal process that transforms a powdered material into a solid, coherent mass using heat and often pressure. The defining characteristic is that the material is heated to a high temperature below its melting point, causing the individual particles to fuse and bond together at their contact points. A clear example is in steel production, where powdered iron ore is heated into solid lumps suitable for a blast furnace, all without ever melting the iron itself.

The core principle of sintering is simple: you can create a strong, solid object from a powder by applying just enough heat for the particles to weld themselves together, enabling the production of complex parts from materials that might be difficult to cast or machine.

How Sintering Fundamentally Works

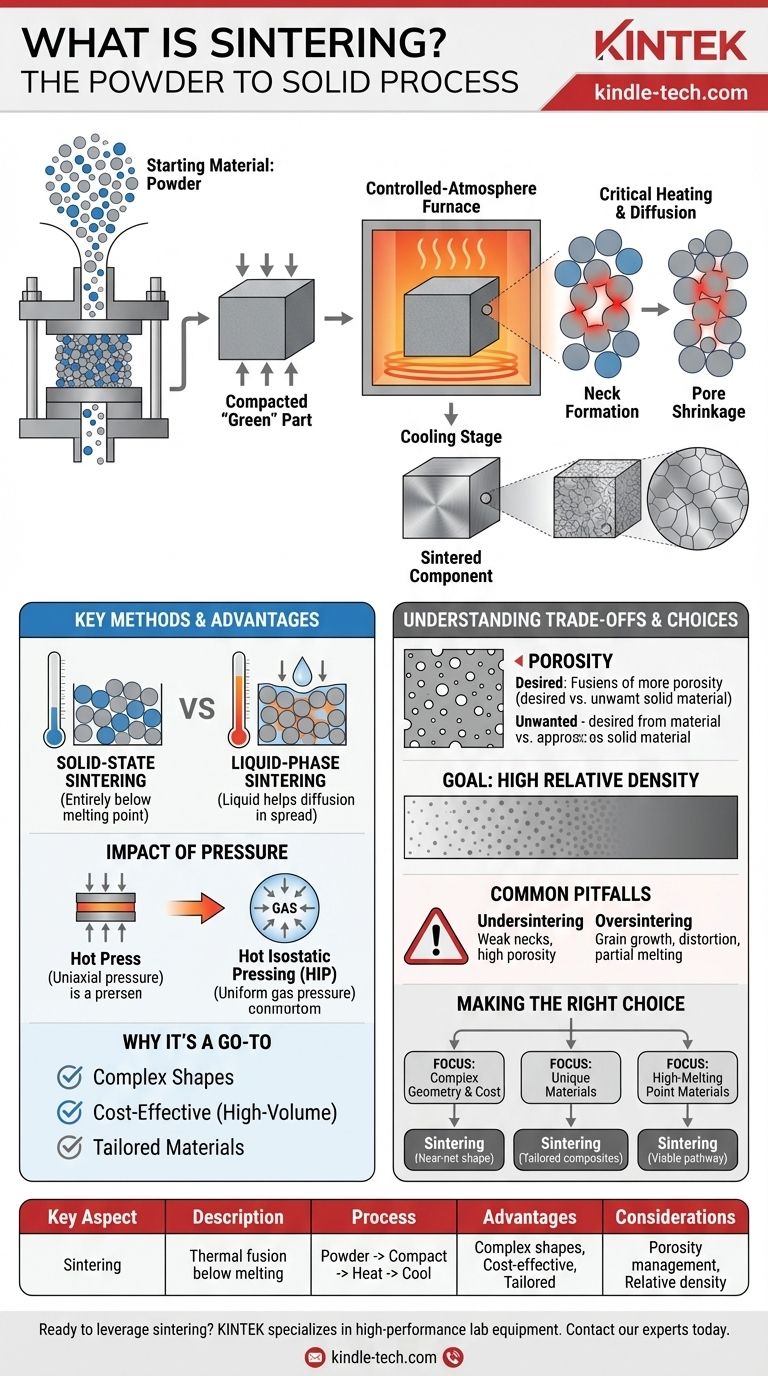

To understand why sintering is so widely used, it’s essential to break down the core stages of the process. Each step contributes to the final properties of the component.

The Starting Material: Powder

The process begins with a base material in powdered form. This could be a metal like iron or tungsten, a ceramic, or a plastic. The size, shape, and purity of these powder particles are critical variables that influence the final product's density and strength.

Compaction and the "Green" Part

The powder is typically poured into a die or mold and compacted under high pressure. This initial step forms the powder into a desired shape, creating what is known as a "green" compact. This part is fragile but has enough mechanical strength to be handled and moved to the next stage.

The Critical Heating Stage

The green part is placed into a controlled-atmosphere furnace (like a mesh belt or walking-beam furnace). As the temperature rises, atomic diffusion accelerates. Atoms from adjacent particles migrate across the boundaries, causing the particles to fuse together and form "necks" at their points of contact.

This neck formation is the heart of the sintering process. As it continues, the voids (or pores) between particles shrink, and the overall part becomes denser and stronger.

Cooling and Final Properties

After being held at the sintering temperature for a specific time, the component is cooled in a controlled manner. This locks in the newly formed microstructure, resulting in a solid part with specific mechanical properties, such as hardness and strength.

Key Sintering Methods and Advantages

Sintering is not a single technique but a family of processes, each with unique capabilities. The method chosen depends on the material and the desired outcome.

Solid-State vs. Liquid-Phase Sintering

In solid-state sintering, the entire material remains below its melting point. In liquid-phase sintering, a mixture of powders is used, and the temperature is raised high enough to melt one of the components. This liquid phase helps accelerate the diffusion and densification process, often resulting in stronger parts.

The Impact of Pressure

Some advanced methods apply external pressure during the heating cycle to achieve superior results.

- Hot Press Sintering simultaneously applies heat and uniaxial pressure.

- Hot Isostatic Pressing (HIP) applies heat and uniform gas pressure from all directions, which is extremely effective at eliminating internal porosity.

Why It's a Go-To Method

The advantages of sintering are significant. It allows for the creation of complex shapes with intricate designs that would be costly or impossible to machine. It is also highly cost-effective for high-volume production and offers remarkable versatility in creating tailored material compositions by blending different powders.

Understanding the Trade-offs

While powerful, the sintered method requires careful control to avoid defects. Understanding its inherent characteristics is key to leveraging it successfully.

The Role of Porosity

Porosity, or the presence of small voids, is a natural feature of sintered parts. In some applications, like self-lubricating bearings or filters, this is a desired feature. However, in structural components, high porosity can reduce strength.

The Goal: Achieving High Relative Density

For most applications, the goal is to achieve a high relative density—meaning the part's density is as close as possible to that of the solid, non-powdered material. This minimizes porosity and maximizes mechanical properties like strength and hardness.

Common Pitfalls to Avoid

- Undersintering: Insufficient time or temperature results in weak neck formation and high porosity, leading to a brittle, underperforming part.

- Oversintering: Excessive time or temperature can cause grain growth, distortion, or even partial melting (known as "sweating"), which degrades the component's properties and dimensional accuracy.

Making the Right Choice for Your Goal

Sintering is a versatile manufacturing process, but its suitability depends entirely on your project's priorities.

- If your primary focus is complex geometry at a low cost: Sintering is an excellent choice for producing large quantities of net-shape or near-net-shape parts, minimizing the need for secondary machining.

- If your primary focus is creating unique materials: Sintering allows you to precisely blend different metals, ceramics, or carbides to create composites with custom-engineered properties.

- If your primary focus is processing high-melting-point materials: Sintering is one of the few viable methods for materials like tungsten or cemented carbides, which are extremely difficult to process via traditional melting and casting.

Ultimately, the sintered method provides a powerful and versatile pathway to engineer high-performance components from the ground up, starting from simple powder.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Thermal treatment of powder below its melting point to fuse particles. |

| Main Stages | Powder Compaction → Heating (Neck Formation) → Controlled Cooling |

| Primary Methods | Solid-State Sintering, Liquid-Phase Sintering, Hot Pressing, Hot Isostatic Pressing (HIP) |

| Key Advantages | Complex shapes, cost-effective mass production, tailored material compositions |

| Key Considerations | Porosity management, achieving high relative density, avoiding under/over-sintering |

Ready to leverage sintering for your laboratory or production needs? KINTEK specializes in high-performance lab equipment, including furnaces essential for precise sintering processes. Whether you are developing new materials or manufacturing complex components, our solutions help you achieve superior results. Contact our experts today to discuss how we can support your project with the right equipment and consumables.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- Why are hydraulic presses dangerous to operate? Uncover the Silent, Deceptive Risks

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- How much psi can a hydraulic press make? From 2,000 PSI to over 50,000 PSI Explained

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing