In the context of injection molding, sintering is the critical final step that transforms a molded part made of powdered material into a solid, dense, and functional component. This is not used in traditional plastic injection molding but is the core of advanced processes like Metal Injection Molding (MIM) and Ceramic Injection Molding (CIM). Sintering uses high heat—below the material's melting point—to fuse the individual powder particles together, creating a solid mass with properties nearly identical to the bulk material.

Sintering is a thermal process that fundamentally changes the nature of a molded part. It converts a fragile object composed of powdered metal or ceramic held together by a binder into a strong, dense final product by fusing the particles together without ever melting the primary material.

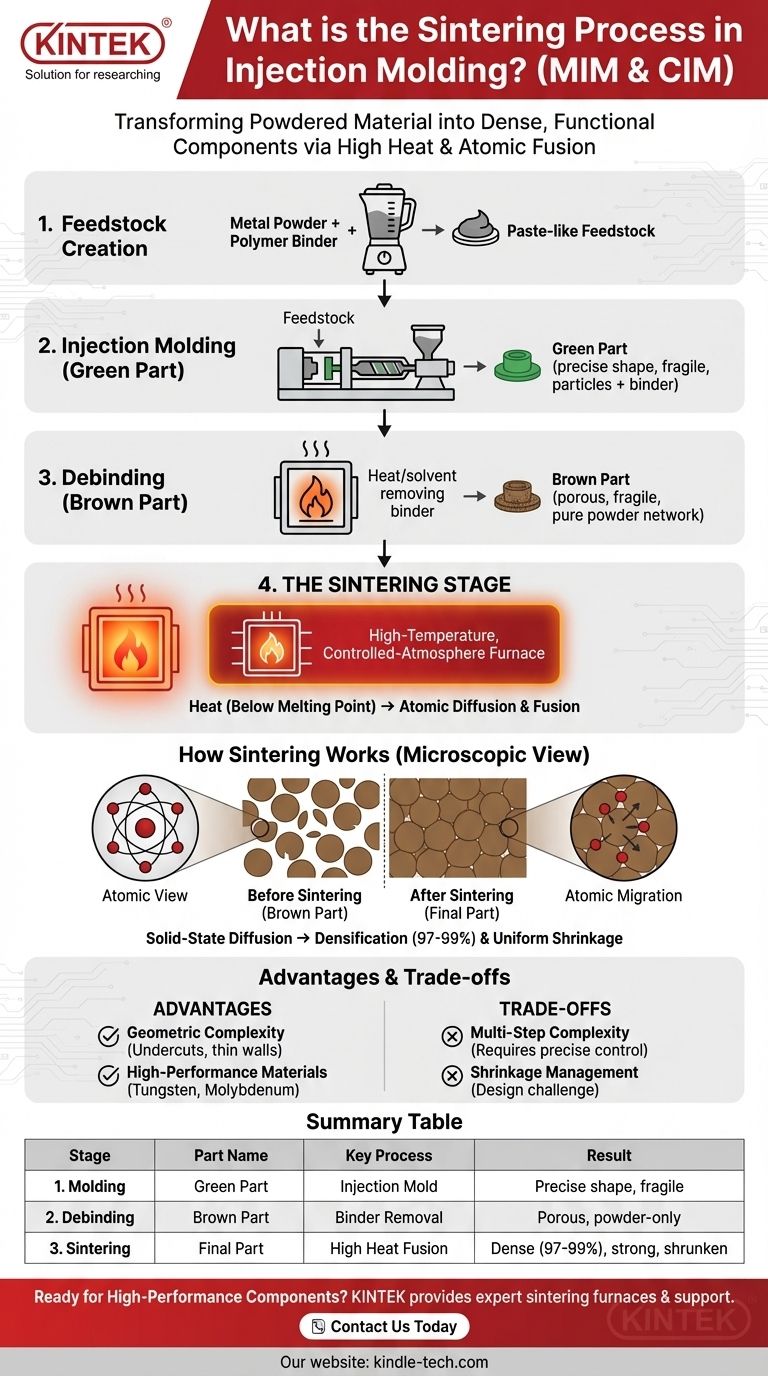

The Sintering-Based Injection Molding Process

To understand sintering's role, you must first understand the multi-stage process it belongs to, most commonly Metal Injection Molding (MIM). This process combines the geometric freedom of plastic injection molding with the material properties of metal.

Step 1: Creating the Feedstock

The process begins by blending extremely fine metal powder with a polymer binder. This creates a feedstock with a paste-like consistency that can be processed in an injection molding machine.

Step 2: Injection Molding the "Green Part"

This feedstock is heated and injected into a mold cavity, just like in conventional plastic injection molding. The resulting part, called a "green part," has the precise shape of the final component but is composed of metal particles held together by the binder.

Step 3: Removing the Binder (Debinding)

The green part is then subjected to a debinding process, often using solvents or heat. This removes the majority of the polymer binder. The part that remains, now called a "brown part," is fragile and porous, consisting of loosely connected metal particles.

Step 4: The Sintering Stage

This is the final, transformative step. The brown part is placed in a high-temperature, controlled-atmosphere furnace. The temperature is raised to just below the melting point of the metal.

How Sintering Works at a Microscopic Level

Sintering is not a simple melting process. It relies on a phenomenon called solid-state diffusion, which dramatically changes the part's internal structure and physical properties.

The Principle of Atomic Diffusion

The high heat provides thermal energy that excites the atoms within the metal particles. This energy allows atoms to migrate across the boundaries where individual particles touch.

As atoms move to fill the voids between particles, the particles fuse together. This process eliminates the porous spaces, creating a single, solid piece.

Densification and Shrinkage

As the voids disappear, the part becomes significantly denser, often achieving 97-99% of the solid material's theoretical density.

This densification is accompanied by a predictable and uniform shrinkage. This shrinkage must be precisely accounted for during the initial mold design to ensure the final part meets dimensional specifications.

Key Advantages and Trade-offs

Sintering-based processes like MIM are powerful but come with specific considerations that are crucial for any technical professional to understand.

Advantage: Geometric Complexity

MIM allows for the creation of small, highly complex metal parts with features like undercuts, thin walls, and intricate details that would be extremely difficult or costly to achieve with traditional CNC machining.

Advantage: High-Performance Materials

Sintering is one of the only viable methods for forming parts from materials with exceptionally high melting points, such as tungsten and molybdenum. These materials cannot be easily cast or machined.

Trade-off: Multi-Step Complexity

The MIM process involves multiple stages (blending, molding, debinding, sintering), each requiring precise control and specialized equipment. It is a more complex workflow than direct machining or casting.

Trade-off: Shrinkage Management

The significant and non-negotiable shrinkage during sintering is the single biggest design challenge. It demands a high level of process expertise and upfront engineering to create a mold that produces dimensionally accurate final parts.

Making the Right Choice for Your Project

Understanding this process allows you to identify where it offers a distinct manufacturing advantage.

- If your primary focus is high-volume production of small, complex metal parts: MIM is often more cost-effective than CNC machining by eliminating material waste and reducing cycle times.

- If your primary focus is working with refractory metals or hard-to-machine alloys: Sintering-based manufacturing is often the most practical or only available method.

- If your primary focus is achieving the properties of wrought metal with the design freedom of molding: The MIM process provides a unique capability to bridge this gap for suitable applications.

Ultimately, mastering the principles of sintering unlocks the ability to produce high-performance components with a level of geometric freedom that other metalworking processes cannot match.

Summary Table:

| Stage | Part Name | Key Process | Result |

|---|---|---|---|

| 1. Molding | Green Part | Powder/binder mix is injection molded | Precise shape, but fragile |

| 2. Debinding | Brown Part | Binder is removed (solvent/heat) | Porous, fragile part of pure powder |

| 3. Sintering | Final Part | High heat fuses particles via diffusion | Dense (97-99%), strong, shrunken part |

Ready to produce complex, high-performance metal or ceramic components?

The sintering process in Metal and Ceramic Injection Molding (MIM/CIM) is complex, but the results are unparalleled for creating dense, intricate parts. KINTEK specializes in providing the high-performance lab furnaces and expert support necessary for precise debinding and sintering cycles.

We help our customers in the MIM and CIM industries achieve consistent results and unlock new design possibilities. Contact us today to discuss how our sintering solutions can enhance your manufacturing capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the most important factor influencing the strength of the brazed joint? Master Joint Clearance for Maximum Strength

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints