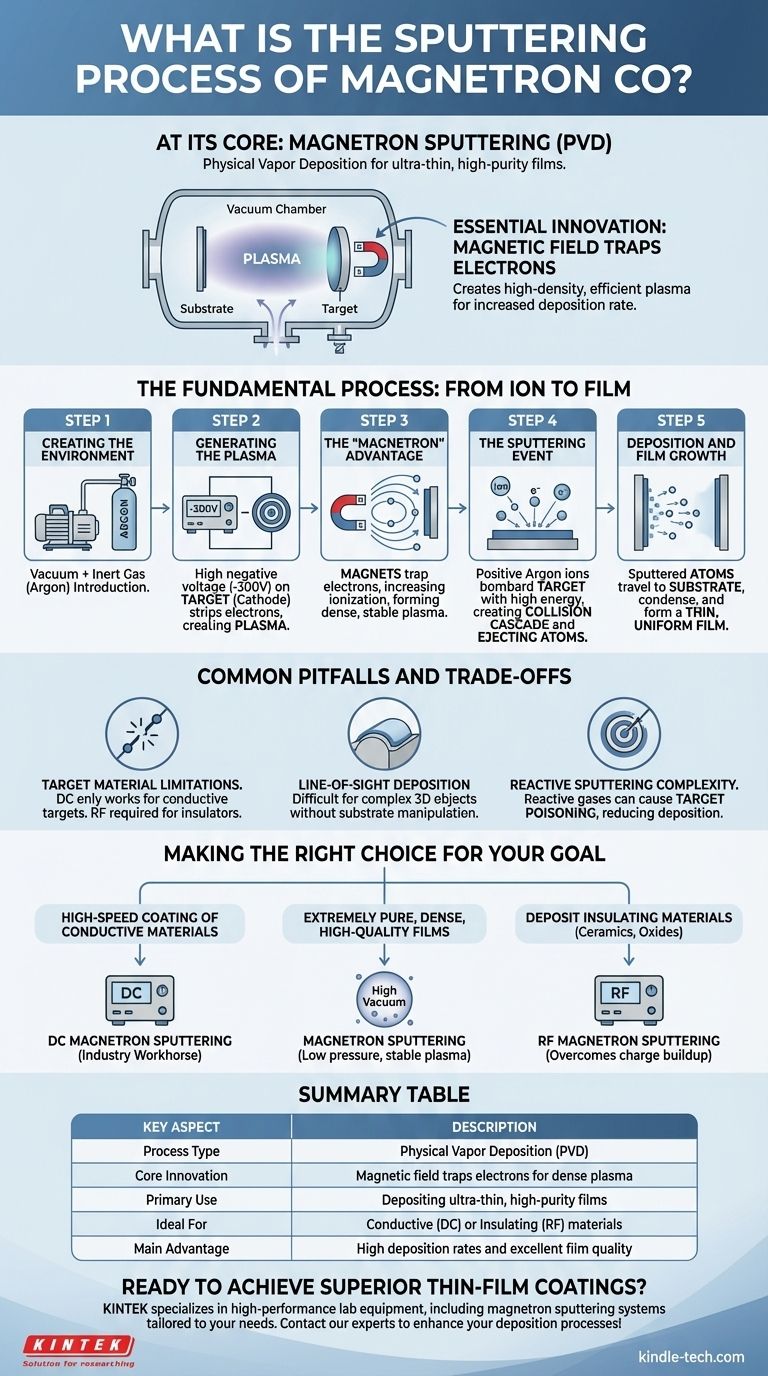

At its core, magnetron sputtering is a physical vapor deposition (PVD) technique used to create ultra-thin films of material. It operates in a vacuum by creating a magnetically-confined plasma of ionized gas. These ions are accelerated into a source material, known as the target, with enough force to knock off, or "sputter," individual atoms, which then travel and condense onto a substrate to form the desired coating.

The essential innovation of magnetron sputtering is not the sputtering itself, but the use of a magnetic field to trap electrons near the target. This creates a highly dense and efficient plasma, dramatically increasing the rate of deposition and improving the quality of the film compared to older methods.

The Fundamental Process: From Ion to Film

To understand how magnetron sputtering works, it's best to break it down into a sequence of critical steps that take place inside a vacuum chamber.

Step 1: Creating the Environment

The entire process must occur in a vacuum. This is done to remove atmospheric gases that could contaminate the film or interfere with the movement of sputtered atoms.

Once a vacuum is established, a small, controlled amount of an inert gas, typically argon, is introduced into the chamber. This gas will become the source of the bombarding ions.

Step 2: Generating the Plasma

A high negative voltage, often around -300V, is applied to the target material, which acts as a cathode. This strong negative charge begins to strip electrons from the argon gas atoms, creating positively charged argon ions and free electrons. This mix of ions and electrons is the plasma.

Step 3: The "Magnetron" Advantage

This is the key to the process. Powerful magnets are placed behind the target. This magnetic field traps the free electrons, forcing them to move in a spiral path close to the face of the target.

Without this magnetic trap, electrons would fly off and be lost. By trapping them, the probability of them colliding with and ionizing more argon atoms increases exponentially. This creates a very dense, stable plasma concentrated directly in front of the target where it is most effective.

Step 4: The Sputtering Event

The strong negative charge on the target aggressively attracts the newly formed positive argon ions. They accelerate and bombard the target surface with significant kinetic energy.

This impact sets off a collision cascade within the target's atomic structure. When this cascade of energy reaches the surface, it can overcome the material's binding energy, ejecting individual atoms of the target material into the vacuum chamber.

Step 5: Deposition and Film Growth

The sputtered atoms from the target travel through the vacuum chamber. When they reach the substrate (the object being coated), they condense on its surface.

Over time, this process builds a thin, uniform, and highly pure film, one atomic layer at a time.

Common Pitfalls and Trade-offs

While powerful, magnetron sputtering is not a universal solution. Understanding its limitations is critical for successful application.

Target Material Limitations

The most common method, DC magnetron sputtering, works exceptionally well for electrically conductive target materials. However, if the target is an insulator, the positive charge from the bombarding ions will build up on its surface, neutralizing the negative bias and stopping the process. This requires using alternative power sources, such as Radio Frequency (RF).

Line-of-Sight Deposition

Sputtering is fundamentally a line-of-sight process. The sputtered atoms travel in a relatively straight line from the target to the substrate. This can make it very difficult to achieve a uniform coating on complex, three-dimensional objects without sophisticated substrate rotation and manipulation.

Reactive Sputtering Complexity

To create compound films (like titanium nitride or aluminum oxide), a reactive gas (like nitrogen or oxygen) is added to the chamber. This process can be difficult to control, as the reactive gas can form an insulating layer on the target itself, a phenomenon known as target poisoning, which can drastically reduce deposition rates.

Making the Right Choice for Your Goal

The method is highly adaptable, but your objective determines the best approach.

- If your primary focus is high-speed coating of conductive materials: Standard DC magnetron sputtering is the industry workhorse, offering excellent deposition rates and process stability.

- If your primary focus is creating extremely pure, dense, and high-quality films: The low-pressure operation and stable, high-density plasma of magnetron sputtering are ideal for minimizing impurities and controlling film structure.

- If your goal is to deposit insulating materials like ceramics or oxides: You must use a variation like RF magnetron sputtering, which overcomes the charge buildup issue inherent in DC systems.

By understanding these core principles, you can effectively leverage a process that builds advanced materials one atom at a time.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Innovation | Magnetic field traps electrons to create a dense plasma |

| Primary Use | Depositing ultra-thin, high-purity films on substrates |

| Ideal For | Conductive materials (DC) or insulating materials (RF) |

| Main Advantage | High deposition rates and excellent film quality |

Ready to achieve superior thin-film coatings for your research or production?

KINTEK specializes in high-performance lab equipment, including magnetron sputtering systems tailored to your specific material and application needs. Whether you're working with conductive metals or insulating ceramics, our expertise ensures you get the precise, high-quality results your laboratory demands.

Contact our experts today to discuss how our solutions can enhance your deposition processes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition