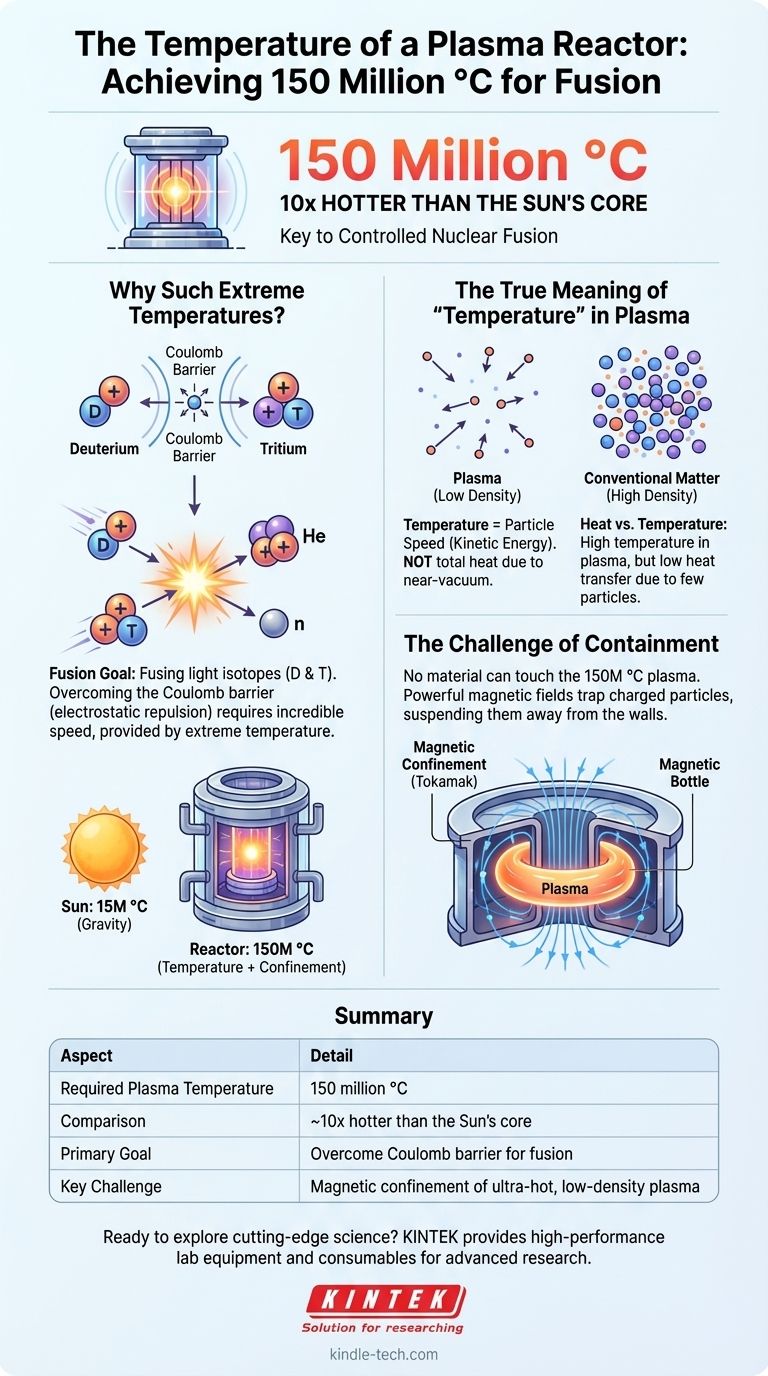

In a fusion reactor like ITER, the plasma must reach an astonishing temperature of 150 million degrees Celsius. This extreme condition, which is approximately ten times hotter than the core of the Sun, is the fundamental requirement to initiate and sustain a controlled nuclear fusion reaction on Earth.

The immense temperature inside a plasma reactor is not about creating conventional "heat," but about giving atomic nuclei enough kinetic energy to overcome their powerful natural repulsion and fuse together, releasing massive amounts of energy.

Why Such Extreme Temperatures are Necessary

To understand the purpose of a plasma reactor, we must first understand its goal: forcing atomic nuclei to fuse. This process, the same one that powers our sun, is governed by fundamental forces that must be overcome.

The Goal: Nuclear Fusion

The primary objective is to fuse light atomic nuclei, typically isotopes of hydrogen like deuterium and tritium. When these nuclei combine, they form a heavier nucleus (helium) and release a tremendous amount of energy.

Overcoming the Coulomb Barrier

Atomic nuclei are positively charged and therefore strongly repel each other. This electrostatic force, known as the Coulomb barrier, prevents them from getting close enough for the short-range strong nuclear force to take over and bind them together.

To overcome this repulsion, the particles must be moving at incredible speeds. In a plasma, temperature is a direct measure of the average kinetic energy, or speed, of its particles. The 150 million °C target provides the necessary velocity to force the nuclei together.

Replicating a Star on Earth

The Sun achieves fusion with a core temperature of "only" 15 million °C because its immense gravitational pressure squeezes particles together. Lacking that stellar-level gravity, Earth-based reactors must compensate by using much higher temperatures to achieve the required rate of fusion reactions.

The True Meaning of "Temperature" in a Plasma

The concept of 150 million degrees can be misleading if viewed through the lens of everyday experience. The nature of temperature in the ultra-low-density environment of a reactor is fundamentally different.

Temperature as Particle Speed

The extreme temperature refers to the speed of individual particles, not the total thermal energy of the system. Each deuterium and tritium ion is moving at an enormous velocity, carrying immense kinetic energy.

The Critical Role of Low Density

A fusion plasma is a near-vacuum. While the particles are incredibly energetic, there are relatively few of them within the reactor volume. The plasma is billions of times less dense than the air we breathe.

Heat vs. Temperature: A Key Distinction

This leads to a critical distinction. If you could place an object inside the plasma, it wouldn't be instantly vaporized as one might think. The temperature is high, but the low density means the total amount of heat transferred upon contact would be small because so few particles would actually hit the object at any given moment.

The Challenge of Containment

Clearly, no physical material can come into contact with a substance at 150 million degrees. This presents one of the greatest engineering challenges in modern science.

No Material Can Withstand This

Any solid material that touched the plasma core would not only be destroyed but would also instantly cool and contaminate the plasma, extinguishing the fusion reaction.

The Solution: Magnetic Confinement

Reactors like ITER, known as tokamaks, solve this by using powerful magnetic fields. These fields create a "magnetic bottle," trapping the charged plasma particles and suspending them in the center of the vacuum vessel, safely away from the metal walls.

Key Insights for Understanding Plasma Reactors

Your perspective on this extreme temperature depends on your primary interest in the technology.

- If your primary focus is the physics: The temperature is simply the tool used to generate the particle velocity required to overcome the fundamental electrostatic repulsion between nuclei.

- If your primary focus is the engineering: The challenge is not just achieving the temperature, but designing a magnetic "cage" strong and stable enough to contain this super-energetic, low-density state of matter.

Ultimately, achieving and controlling a 150 million degree plasma is the monumental task of harnessing the power of a star within a machine on Earth.

Summary Table:

| Aspect | Detail |

|---|---|

| Required Plasma Temperature | 150 million °C |

| Comparison | ~10x hotter than the Sun's core |

| Primary Goal | Overcome Coulomb barrier for nuclear fusion |

| Key Challenge | Magnetic confinement of ultra-hot, low-density plasma |

Ready to explore the cutting-edge science behind plasma reactors? The extreme conditions required for fusion demand unparalleled precision in equipment and instrumentation. At KINTEK, we specialize in providing high-performance lab equipment and consumables that support advanced research and development. Whether you're working on materials testing for containment systems or developing diagnostics for high-temperature environments, our solutions are designed to meet the rigorous demands of your laboratory. Let's discuss how we can support your groundbreaking work—contact our experts today to learn more.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Laboratory High Pressure Vacuum Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation