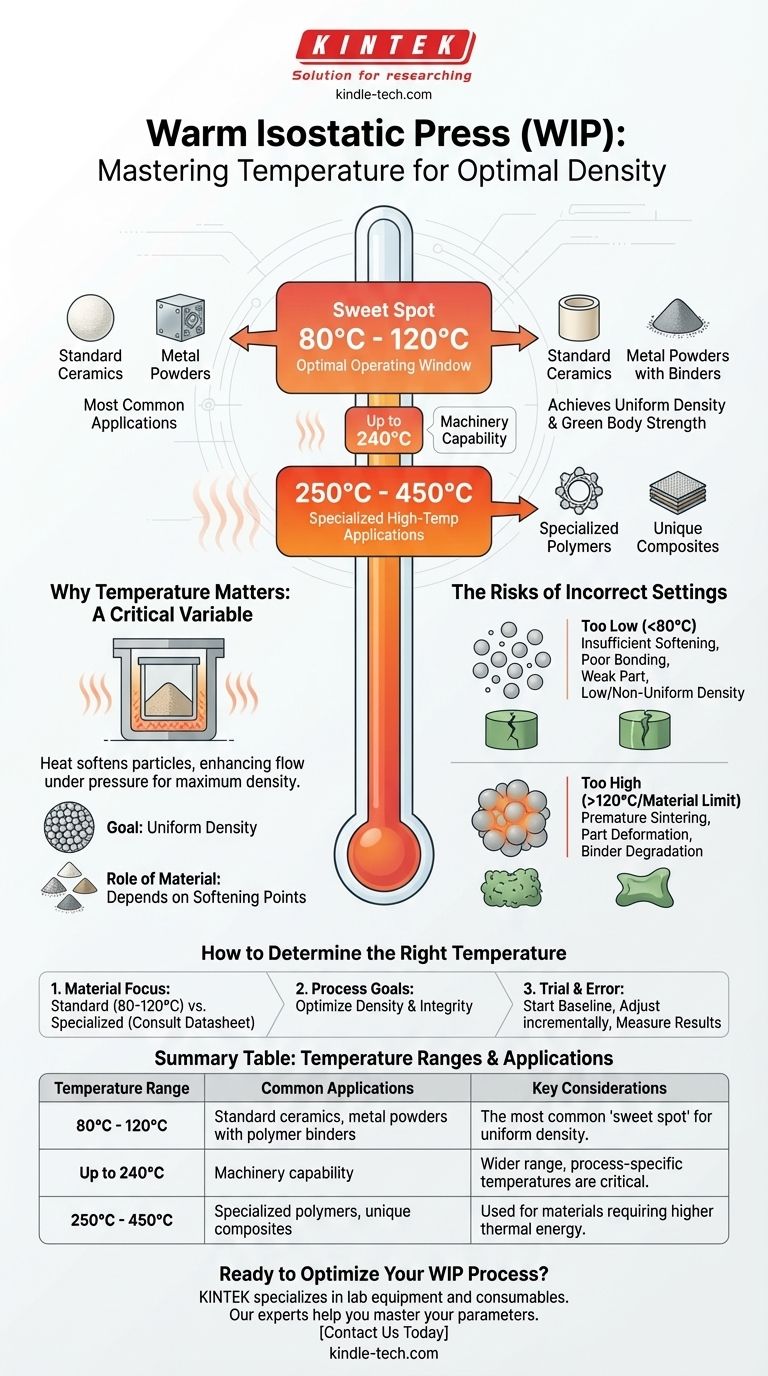

In short, the typical operating temperature for a warm isostatic press (WIP) is between 80°C and 120°C. While the machinery itself may be capable of a wider range, sometimes up to 240°C, this specific window is where most industrial processes achieve their desired results for densifying powder materials.

The core principle to understand is that temperature in a WIP is not a fixed setting but a critical process variable. It must be precisely matched to the specific powder material to achieve maximum density without causing unwanted sintering or part deformation.

Why Temperature is a Critical Variable

Warm Isostatic Pressing combines uniform pressure with elevated temperature to form a solid, dense part from a powder. The temperature component is essential for softening the powder particles just enough to facilitate this process.

The Goal: Uniform Density

The primary objective of WIP is to create a "green body"—an unfired part—with high and uniform density. Heat makes the powder particles more plastic, allowing them to deform and pack together more tightly under the immense, uniform pressure (often around 300 MPa).

This results in a stronger, more consistent part after the final sintering stage.

The Role of Material Characteristics

The ideal temperature is entirely dependent on the material being pressed. Different powders, and especially the binders mixed with them, have different softening points.

The goal is to operate above the material's glass transition temperature but well below its melting or sintering point. This allows the particles to flow without fundamentally changing their structure.

Understanding the Temperature Ranges

The specific temperature you use is a function of your material and process goals. It's crucial to distinguish between what the machine can do and what the process requires.

The Common Operating Window (80°C - 120°C)

This range is the sweet spot for a wide variety of materials, particularly ceramics or metal powders mixed with polymer binders. It's hot enough to soften the binder, which acts as a lubricant and helps the primary powder particles slide into a dense configuration.

Higher Temperature Applications (250°C - 450°C)

Some specialized processes, often involving polymers or other unique materials, may require these higher temperatures. These are less common but are used when the material's properties demand more thermal energy to achieve plasticity.

The Trade-offs of Incorrect Temperature Settings

Selecting the wrong temperature is one of the most common failure points in warm isostatic pressing, leading to wasted time and material.

The Consequence of Temperatures Too Low

If the temperature is insufficient, the powder particles or binder will not soften properly. The applied pressure will be less effective, resulting in low or non-uniform density, poor particle bonding, and a weak final part.

The Danger of Temperatures Too High

If the temperature is excessive, you risk several negative outcomes. The powder may begin to prematurely sinter, the part can deform under pressure, or the organic binders can degrade, compromising the integrity of the green body.

How to Determine the Right Temperature for Your Application

Choosing the correct temperature is a matter of matching the process to your material's specific thermal properties.

- If your primary focus is pressing standard ceramics or metals with a polymer binder: Begin your process development within the 80°C to 120°C range.

- If your primary focus is a specialized polymer or unique composite: You must consult the material's datasheet for its glass transition temperature and softening point to establish a safe and effective operating window.

- If your primary focus is process optimization: Start with a baseline temperature recommended for your material and make small, incremental adjustments while measuring the density and integrity of the resulting parts.

Ultimately, mastering temperature control is the key to unlocking the full potential and consistency of the warm isostatic pressing process.

Summary Table:

| Temperature Range | Common Applications | Key Considerations |

|---|---|---|

| 80°C - 120°C | Standard ceramics, metal powders with polymer binders | The most common 'sweet spot' for achieving uniform density. |

| Up to 240°C | Machinery capability | Wider range, but process-specific temperatures are critical. |

| 250°C - 450°C | Specialized polymers, unique composites | Used for materials requiring higher thermal energy for plasticity. |

Ready to optimize your Warm Isostatic Pressing process?

Choosing the correct temperature is critical for achieving maximum density and part integrity. KINTEK specializes in lab equipment and consumables, providing the expertise and reliable machinery you need to master your WIP parameters.

Our team can help you select the right press and consumables for your specific materials, ensuring consistent, high-quality results.

Contact our experts today to discuss your application and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What are the parameters of hot isostatic pressing? Master Temperature, Pressure & Time for Full Densification

- What is the hot isostatic pressing cycle? A Guide to HIP for Superior Material Integrity

- What is hot isostatic pressing treatment porosity? Achieve 100% Material Density for Critical Components

- What is the temperature and pressure for hot isostatic pressing? Achieve 100% Dense, High-Performance Materials

- What are the conditions for hot isostatic pressing? Unlock Maximum Material Density

- How does Hot Isostatic Press (HIP) enhance Si3N4 and h-BN ceramics? Achieving Full Density and Isotropy

- What is the purpose of using a high-vacuum diffusion pump system for pre-treating powder capsules in HIP? Avoid PPBs