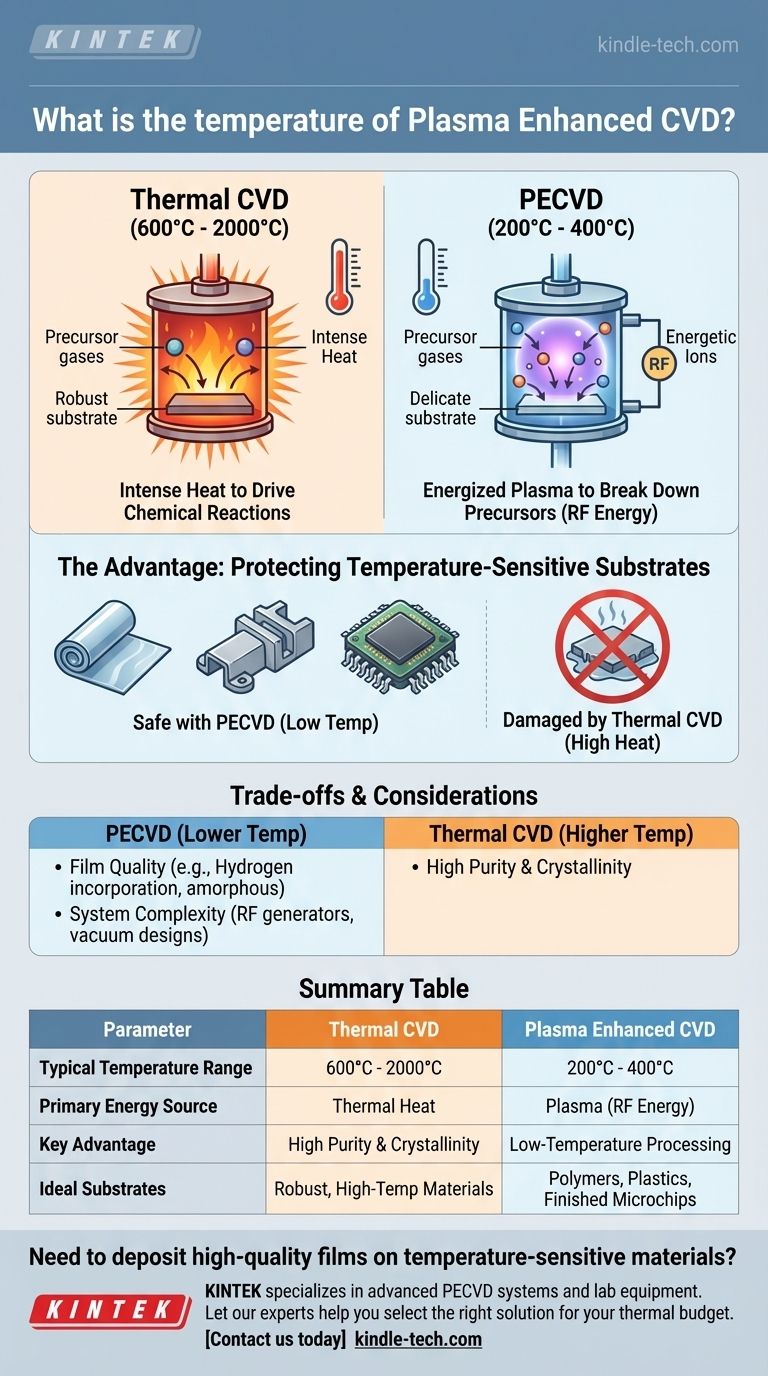

To be clear, Plasma Enhanced Chemical Vapor Deposition (PECVD) operates at significantly lower temperatures than conventional thermal CVD processes. While thermal CVD requires temperatures from 600°C to over 1100°C, PECVD typically operates in a much cooler range, often between 200°C and 400°C.

The core difference is the energy source. Instead of relying on extreme heat to drive chemical reactions, PECVD uses an energized plasma to break down precursor gases, enabling high-quality film deposition on substrates that could not withstand high temperatures.

The Fundamental Difference: Thermal vs. Plasma Energy

Understanding the role of energy is key to grasping why PECVD is a distinct and valuable process. Both methods aim to deposit a solid film from a gas, but they achieve it in fundamentally different ways.

How Thermal CVD Works

Traditional Chemical Vapor Deposition (CVD) is a thermally-driven process. It requires very high temperatures, often in the range of 800°C to 2000°C.

This intense heat provides the necessary activation energy to cause the precursor gases to react or decompose on the substrate surface, forming the desired thin film.

How PECVD Works

PECVD replaces the need for extreme thermal energy with energy from a plasma.

An electric field (typically Radio Frequency, or RF) is used to ionize the precursor gases, creating a highly reactive plasma. The energetic electrons and ions in the plasma provide the energy to break chemical bonds and drive the deposition reaction. This allows the substrate to remain at a much lower temperature.

The Advantage of Lower Temperature Deposition

The ability to operate at reduced temperatures is the primary advantage of the PECVD technique and opens up a wide range of applications that are impossible for thermal CVD.

Protecting Temperature-Sensitive Substrates

The most significant benefit is the ability to deposit films on materials with low melting or degradation points.

This includes polymers, plastics, and fully-fabricated semiconductor devices that contain metallic interconnects or other structures that would be damaged or destroyed by the high heat of thermal CVD.

Expanding Material Possibilities

PECVD is frequently used for depositing critical films in modern electronics and materials science.

Common applications include depositing silicon nitride (SiN) or silicon dioxide (SiO₂) for electrical insulation on microchips, creating silicon carbide (SiC) films, and growing vertically aligned carbon nanotubes.

Understanding the Trade-offs

While powerful, the PECVD process involves trade-offs that must be considered for any specific application. Choosing a deposition method is not just about temperature.

Film Quality and Composition

Because the deposition occurs at lower temperatures, PECVD films can sometimes have different properties than their high-temperature counterparts.

For example, films may have a higher concentration of incorporated hydrogen from precursor gases, which can affect optical or electrical properties. They may also be less dense or have an amorphous structure rather than a crystalline one.

System Complexity

A PECVD system is inherently more complex than a simple thermal CVD reactor.

It requires additional hardware, including RF power generators, matching networks to control the plasma, and more sophisticated vacuum chamber designs. This can increase both the cost and the complexity of operation and maintenance.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on the requirements of your substrate and the desired properties of the final film.

- If your primary focus is the highest possible film purity and crystallinity on a robust substrate: Thermal CVD is often the superior choice, as the high temperature promotes ideal chemical reactions and film structure.

- If your primary focus is depositing a film on a temperature-sensitive substrate like a polymer or a completed microchip: PECVD is the essential and enabling technology.

- If your primary focus is balancing processing speed with moderate temperature constraints: PECVD frequently offers higher deposition rates than other low-temperature methods, making it a practical choice for manufacturing.

Ultimately, matching the process to the material's thermal budget is the most critical decision in thin-film deposition.

Summary Table:

| Parameter | Thermal CVD | Plasma Enhanced CVD (PECVD) |

|---|---|---|

| Typical Temperature Range | 600°C - 2000°C | 200°C - 400°C |

| Primary Energy Source | Thermal Heat | Plasma (RF Energy) |

| Key Advantage | High Purity & Crystallinity | Low-Temperature Processing |

| Ideal Substrates | Robust, High-Temp Materials | Polymers, Plastics, Finished Microchips |

Need to deposit high-quality films on temperature-sensitive materials? KINTEK specializes in advanced PECVD systems and lab equipment, enabling precise thin-film deposition for semiconductor, polymer, and materials science applications. Let our experts help you select the right solution for your thermal budget and performance goals. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth