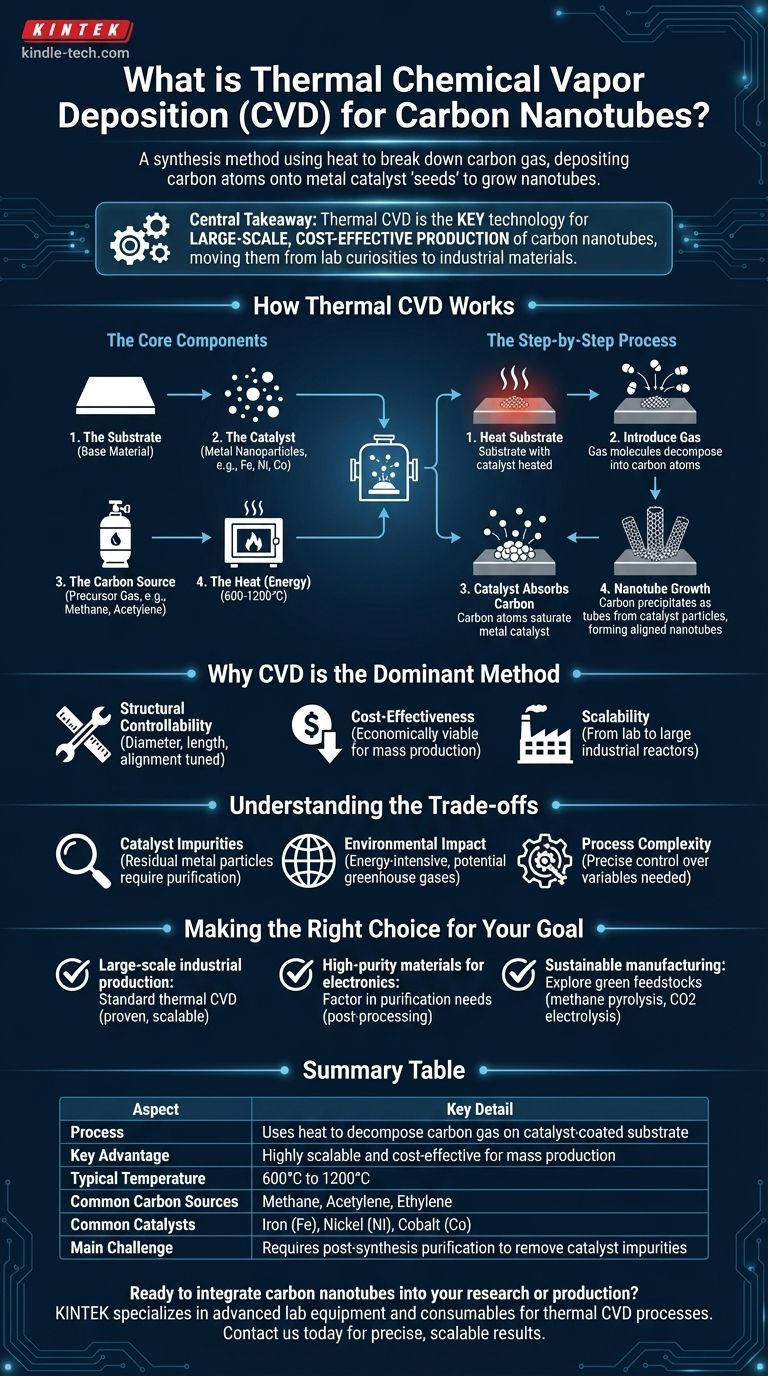

At its core, thermal chemical vapor deposition (CVD) for carbon nanotubes is a synthesis method that uses heat to break down a carbon-containing gas. These carbon atoms are then deposited onto a surface prepared with tiny metal catalyst particles, which serve as the "seeds" from which the nanotubes grow. It has become the dominant commercial process due to its scalability and control over the final product.

The central takeaway is that thermal CVD is not just one of many methods; it is the key technology that made the large-scale, cost-effective production of carbon nanotubes possible, moving them from laboratory curiosities to viable industrial materials.

How Thermal CVD Works

The elegance of the CVD process lies in its fundamental components and controlled sequence. It transforms a simple gas into a highly structured nanomaterial through a carefully managed chemical reaction.

The Core Components

The process relies on four key elements working in concert inside a reaction chamber or furnace.

- The Substrate: This is the base material upon which the nanotubes will be grown.

- The Catalyst: Typically a thin layer or nanoparticles of metal (like iron, nickel, or cobalt) are deposited onto the substrate. These particles are crucial for nucleating and guiding nanotube growth.

- The Carbon Source: A volatile, carbon-rich gas (a "precursor") is introduced into the chamber. Common examples include methane, acetylene, or ethylene.

- The Heat (Energy): A furnace heats the chamber to a high temperature (typically 600-1200°C). This thermal energy is what breaks down the precursor gas and drives the entire reaction.

The Step-by-Step Process

The growth of a carbon nanotube via thermal CVD follows a precise sequence.

First, the substrate with its catalyst coating is heated to the target reaction temperature inside the furnace.

Next, the carbon-containing gas is introduced. The high heat causes the gas molecules to decompose, releasing free carbon atoms into the chamber.

These carbon atoms are then absorbed by the nanoscale metal catalyst particles.

Finally, when a catalyst particle becomes supersaturated with carbon, the carbon begins to precipitate out in a highly organized, cylindrical structure—forming the carbon nanotube. This process continues as long as the gas supply and high temperature are maintained.

Why CVD is the Dominant Method

While older methods like arc discharge and laser ablation can produce high-quality nanotubes, they are difficult to scale. CVD surpassed them for several key reasons.

Structural Controllability

CVD offers a significant degree of control over the final nanotube structure. By carefully tuning parameters like temperature, gas pressure, and catalyst type, operators can influence the diameter, length, and even alignment of the nanotubes.

Cost-Effectiveness

Compared to the extreme energy requirements of laser ablation or arc discharge, CVD is a more economically viable process for mass production. This cost-effectiveness is a primary driver of its adoption in commercial applications.

Scalability

The fundamental process of CVD is highly scalable. It can be adapted from small laboratory setups to large industrial reactors capable of producing kilograms of material, a feat unachievable with earlier methods.

Understanding the Trade-offs

Despite its advantages, the CVD process is not without challenges. Understanding its limitations is critical for practical application.

Catalyst Impurities

Because the process relies on a metal catalyst, the final carbon nanotube product often contains residual metal particles. These impurities can negatively affect the material's properties and usually require a separate, often complex, purification step.

Environmental Impact

The synthesis process is the main source of potential ecotoxicity. It is an energy-intensive method that consumes significant power and can result in greenhouse gas emissions, depending on the precursor gas used.

Process Complexity

Achieving consistent, high-quality results requires precise control over numerous variables. Minor fluctuations in temperature, gas flow rates, or catalyst deposition can lead to variations in the final product, demanding sophisticated engineering and process monitoring.

Making the Right Choice for Your Goal

Selecting or refining a CVD process depends entirely on your end goal. The trade-offs between cost, purity, and environmental impact must be carefully weighed.

- If your primary focus is large-scale industrial production: Standard thermal CVD is the most proven, scalable, and cost-effective route for manufacturing carbon nanotubes in bulk.

- If your primary focus is high-purity materials for electronics: You must factor in the need for robust post-processing and purification techniques to remove metallic catalyst residues.

- If your primary focus is sustainable manufacturing: Explore emerging CVD variations that utilize green feedstocks, such as methane pyrolysis or the electrolysis of captured carbon dioxide, to reduce the environmental footprint.

Ultimately, mastering the CVD process is about understanding how to manipulate fundamental chemical and physical principles to build advanced materials from the atom up.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Uses heat to decompose a carbon gas on a catalyst-coated substrate. |

| Key Advantage | Highly scalable and cost-effective for mass production. |

| Typical Temperature | 600°C to 1200°C |

| Common Carbon Sources | Methane, Acetylene, Ethylene |

| Common Catalysts | Iron (Fe), Nickel (Ni), Cobalt (Co) |

| Main Challenge | Requires post-synthesis purification to remove catalyst impurities. |

Ready to integrate carbon nanotubes into your research or production?

The controlled synthesis of high-quality carbon nanotubes is critical for applications in electronics, composites, and energy storage. KINTEK specializes in providing the advanced lab equipment and consumables necessary for thermal CVD processes, helping you achieve precise, scalable results.

Our experts can help you select the right tools to optimize your nanotube growth, from substrates and catalysts to reactor systems. Contact us today to discuss your specific needs and how our solutions can accelerate your nanotechnology projects.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the core function of the CVD deposition furnace? Master Bulk ZnS Production with Precision Control

- What role does a high-purity carbon heating block play inside an AACVD reactor? Key to Precision Thin Film Growth

- What is CVD technique for thin film? Build Superior, High-Performance Coatings

- What coating methods are applied for metal cutting tools? PVD vs. CVD for Superior Tool Performance

- How does a hollow-type dielectric window compare to a planar quartz window? Boost Plasma CVD Uniformity

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the thinnest coating? Unlocking Unique Properties at the Atomic Scale

- What are the methods of chemical vapour deposition? A Guide to APCVD, LPCVD, and PECVD