In injection molding, the top half of the mold is most commonly referred to as the cavity. This section is typically concave and forms the external, often cosmetic, surface of the final product—the side that users will see and touch. It works in tandem with the bottom half, known as the core, to create the finished part.

The fundamental concept to grasp is that an injection mold is a two-part system. The cavity (A-Side) forms the part's exterior cosmetic surface, while the core (B-Side) forms its interior and structural features.

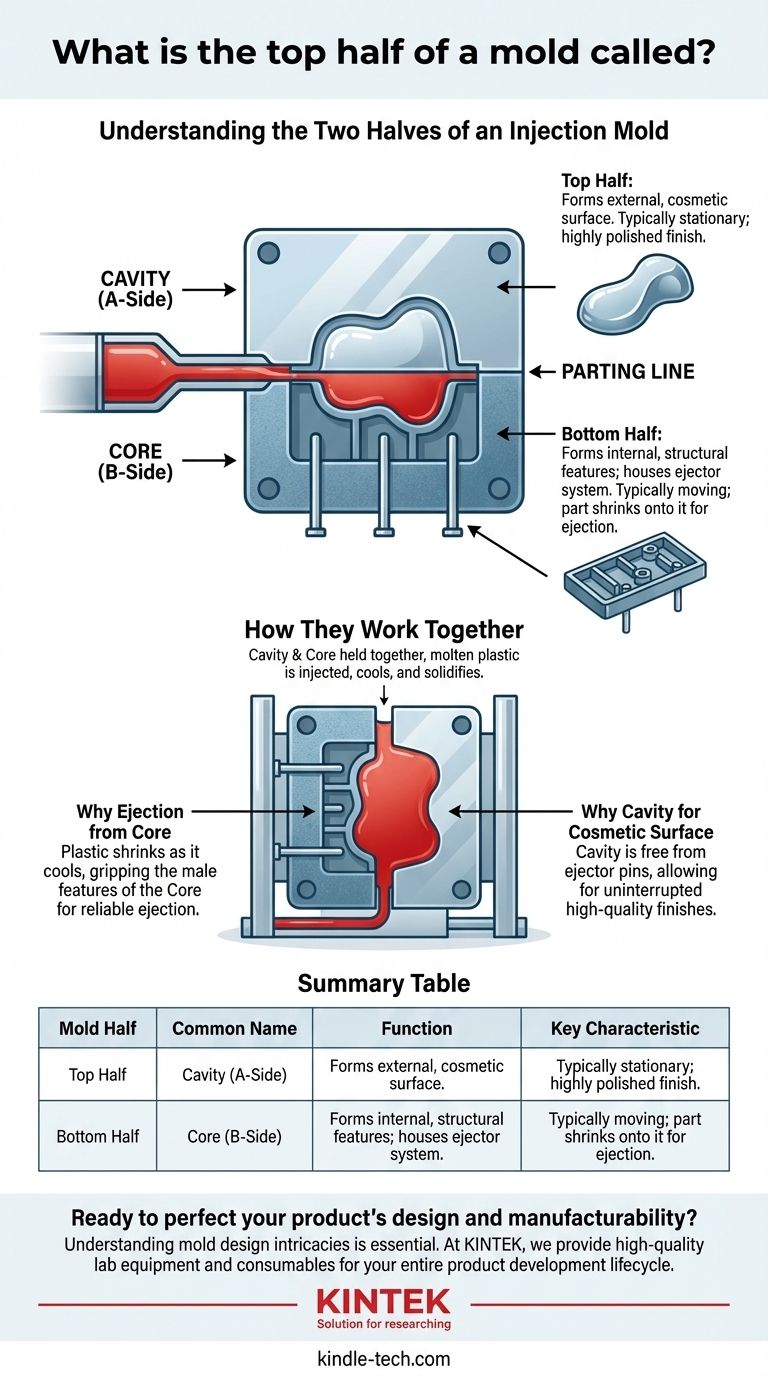

The Two Halves of an Injection Mold

Every injection mold is built around a fundamental split between two halves. This design allows the mold to open and securely eject the plastic part after it has cooled and solidified.

The Cavity (The "A-Side")

The cavity is the half of the mold that is typically stationary and fixed to the injection molding machine. It's often called the "A-Side" of the tool.

This section is carefully machined and polished to create the final aesthetic of the product. Because it forms the "show surface," its finish (whether glossy, matte, or textured) is critical to the part's quality.

The Core (The "B-Side")

The opposing half of the mold is the core. It is typically attached to the moving side of the molding press and is often called the "B-Side."

The core is generally convex, fitting into the cavity. It forms the internal, non-cosmetic features of the part, such as ribs, bosses, and support structures. This side also contains the ejector system (pins, sleeves, etc.) that pushes the part out once the mold opens.

How They Work Together

When the mold is closed, the two halves are held together under immense pressure. The edge where the cavity and core meet is called the parting line.

Molten plastic is then injected into the empty space—the impression—formed between the cavity and the core. The plastic fills this space, cools, and solidifies, taking on the precise shape of the combined mold halves.

Understanding the Design Implications

The division between the cavity and core is not arbitrary; it is a critical engineering decision that impacts the part's quality, functionality, and manufacturability.

Why the Part Ejects from the Core

As plastic cools, it shrinks. This natural shrinkage causes the part to grip tightly onto the male features of the core.

This is an intentional design element. By ensuring the part sticks to the core (the B-Side), the ejector pins housed there have a solid surface to push against, guaranteeing a clean and consistent ejection cycle after the mold opens.

Why the Cavity Forms the Cosmetic Surface

The cavity is responsible for the product's final look and feel. It is free from the complex mechanisms like ejector pins that can leave small marks on the plastic surface.

This separation of duties allows designers to specify a high-quality finish for the cavity side without worrying about interruptions from the mechanical elements required to get the part out of the tool.

Making the Right Choice for Your Goal

Understanding this terminology is the first step toward effective communication with designers, engineers, and manufacturers.

- If your primary focus is the final appearance of a product: Concentrate on the design and finish of the cavity (A-Side), as it dictates the cosmetic quality.

- If your primary focus is structural integrity or part ejection: Your analysis should center on the core (B-Side), which forms internal features and houses the ejection system.

- If your primary focus is minimizing visible seams: You must carefully consider the location of the parting line where the cavity and core meet.

Mastering the distinction between the cavity and the core empowers you to make more informed decisions throughout the product development process.

Summary Table:

| Mold Half | Common Name | Function | Key Characteristic |

|---|---|---|---|

| Top Half | Cavity (A-Side) | Forms the external, cosmetic surface of the part. | Typically stationary; highly polished finish. |

| Bottom Half | Core (B-Side) | Forms the internal, structural features; houses the ejector system. | Typically moving; part shrinks onto it for ejection. |

Ready to perfect your product's design and manufacturability?

Understanding the intricacies of mold design, like the critical roles of the cavity and core, is essential for a successful outcome. At KINTEK, we specialize in providing the high-quality lab equipment and consumables that support the entire product development lifecycle—from prototyping to production.

Whether you're refining a cosmetic surface or optimizing part ejection, having the right tools makes all the difference. Contact our experts today to discuss how KINTEK's solutions can enhance your lab's capabilities and bring your injection molding projects to life with precision and efficiency.

Visual Guide

Related Products

- High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Custom PTFE Teflon Parts Manufacturer for PTFE Stirring Bar Recovery Rod

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What are the key functions of high-temperature graphite molds? Optimize Vacuum Hot Pressing for W-50%Cu Composites

- What is a 3 plate mold structure? Achieve Automatic Degating and Design Flexibility

- What are the primary functions of a stainless steel mold in CSP? Enhancing CaF2 Ceramic Densification

- What is the difference between two-plate and three-plate injection molds? Choose the Right Tool for Your Plastic Part

- What is the function of graphite molds during hot pressing of Tantalum Carbide? Optimize Your TaC Ceramic Densification

- What is press molding in ceramics? Achieve Unmatched Precision & Strength for Your Components

- What is the significance of applying different pressure levels during the assembly of all-solid-state batteries in molds?

- What are the primary functions of a graphite mold? Optimize Vacuum Hot Pressing for Cu-Zn Composites