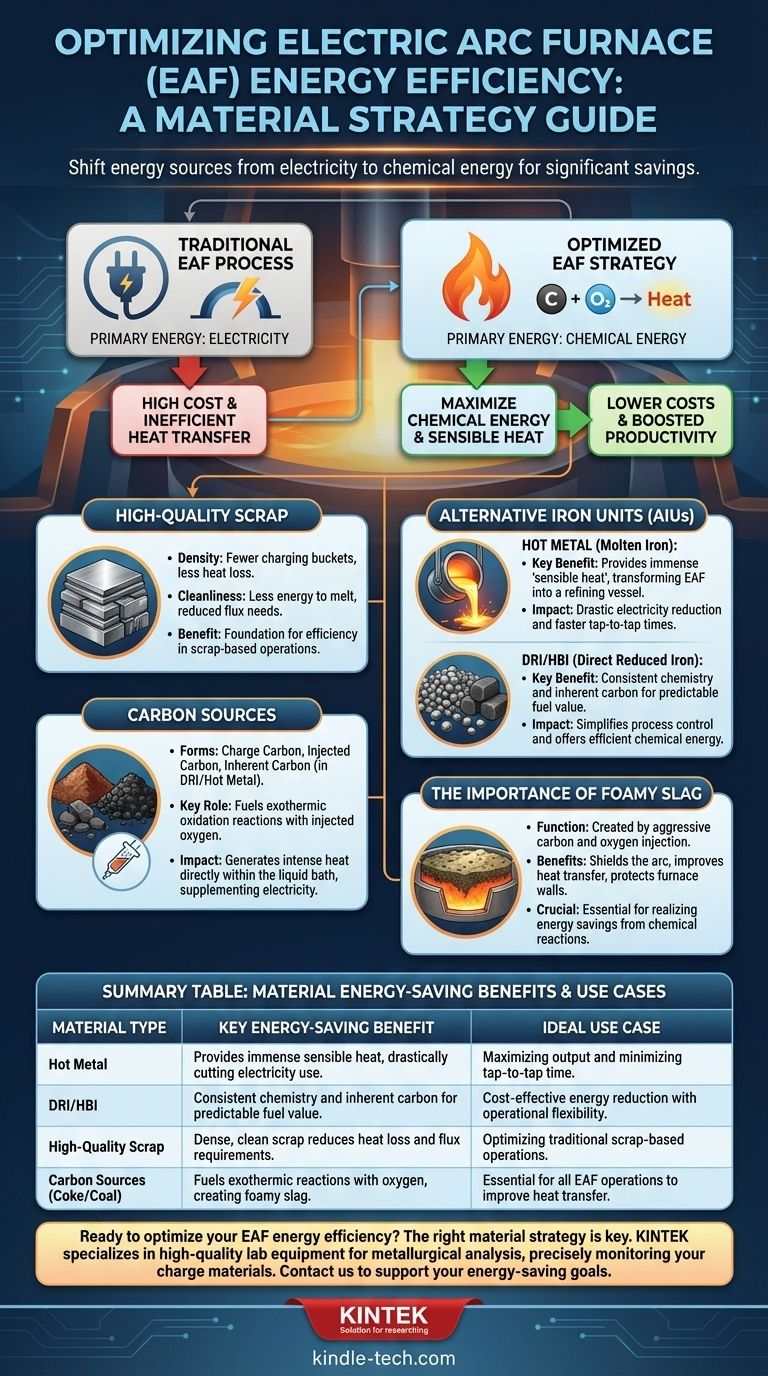

At its core, the most effective way to save energy in an electric arc furnace (EAF) is not by using a single type of material, but by strategically shifting the energy source away from electricity. This is achieved by maximizing the use of materials that provide chemical energy, such as carbon, and alternative iron units with high sensible heat, like hot metal, or fuel value, like Direct Reduced Iron (DRI).

The fundamental strategy for EAF energy saving is to substitute expensive electrical energy with more efficient and cost-effective chemical energy. Your choice of charge materials is the primary lever you have to control this substitution.

The Dual Role of Energy: Electrical vs. Chemical

To understand material selection, you must first understand the two types of energy at play in a modern EAF. The goal is to optimize the balance between them.

The Limits of Electrical Energy

The "arc" in Electric Arc Furnace refers to the massive electrical current that melts the metallic charge. This is the primary energy source in traditional designs.

However, relying solely on electricity has drawbacks. It is often the most expensive component of steelmaking cost, and transferring heat from the arc to the entire steel bath can be inefficient, especially without a proper slag cover.

Unlocking Chemical Energy

Modern EAFs supplement electrical input with chemical energy derived from exothermic (heat-releasing) reactions inside the furnace. This is the key to significant energy savings.

The most important reaction is the oxidation of carbon. By injecting oxygen (O₂) to react with carbon (C) from the charge materials, you generate intense heat directly within the liquid bath, significantly reducing the required electrical input.

Key Materials for Maximizing Energy Efficiency

Your material choice directly impacts your ability to leverage chemical energy and improve overall thermal efficiency.

1. High-Quality Scrap

The quality of your steel scrap is the foundation.

- Density: Using dense, heavy-melt scrap allows for a smaller number of charging buckets. This reduces the time the furnace roof is open, minimizing heat loss and improving productivity.

- Cleanliness: Clean scrap, free from dirt, oil, and non-metallics, requires less energy to melt and reduces the need for fluxes to manage unwanted slag, saving both energy and material costs.

2. Alternative Iron Units (AIUs)

AIUs are sources of iron other than scrap and are critical for high-efficiency operations.

Hot Metal: The Ultimate Energy Saver

Charging liquid hot metal (molten iron from a blast furnace or other smelter) provides the single largest energy-saving opportunity.

The material is already molten, bringing immense "sensible heat" into the furnace. This transforms the EAF from a melting unit into a refining vessel, drastically cutting electricity consumption and tap-to-tap times.

DRI/HBI: Consistent Chemistry and Fuel Value

Direct Reduced Iron (DRI) and its compacted form, Hot Briquetted Iron (HBI), are excellent energy-saving materials.

They have a known, consistent chemical composition, which simplifies process control. Crucially, they contain a controlled amount of carbon that acts as a predictable and highly efficient fuel source when combined with oxygen injection.

3. Carbon Sources

Carbon is not just an element in steel; it is a primary fuel in the EAF. It can be introduced in several forms:

- Charge Carbon: Added with the scrap charge, typically as coke or coal.

- Injected Carbon: Blown into the furnace to react with oxygen and create a foamy slag.

- Inherent Carbon: The carbon present in hot metal or DRI/HBI.

Mastering carbon injection is essential for creating a foamy slag, which shields the arc, improves heat transfer to the bath, and protects the furnace walls from radiation, all of which contribute to energy savings.

Understanding the Trade-offs and Practical Realities

While these materials offer significant energy savings, their use is governed by practical and economic constraints.

Cost and Availability

High-quality, dense scrap commands a premium price. The use of hot metal is only feasible for integrated steel plants with an operating blast furnace. DRI and HBI have their own production costs and are subject to global market pricing and availability.

Operational Complexity

An EAF designed to charge hot metal or continuously feed DRI is operationally different and more complex than a simple scrap-charging furnace. It requires specialized equipment, logistics, and operator skill.

The Importance of Foamy Slag

Aggressively using carbon and oxygen for chemical energy without maintaining a good, foamy slag is counterproductive. An unstable or thin slag leads to poor heat transfer, excessive refractory wear, and lower metallic yield, negating any potential energy savings.

Making the Right Choice for Your Goal

The optimal material mix depends entirely on your plant's configuration, location, and strategic objectives.

- If your primary focus is maximizing output and minimizing tap-to-tap time: A high percentage of hot metal in the charge is the unparalleled choice, effectively turning your EAF into a high-speed steel converter.

- If your primary focus is cost-effective energy reduction with operational flexibility: Incorporating a mix of DRI/HBI and high-quality scrap, paired with proficient carbon and oxygen injection, is the most balanced and widely adopted approach.

- If your primary focus is optimizing a traditional scrap-based operation: Prioritizing the procurement of dense, clean scrap and mastering a foamy slag practice is the most critical path to saving energy.

Ultimately, saving energy in an EAF is achieved by viewing your charge materials not just as metal inputs, but as key components of a comprehensive energy strategy.

Summary Table:

| Material Type | Key Energy-Saving Benefit | Ideal Use Case |

|---|---|---|

| Hot Metal | Provides immense sensible heat, drastically cutting electricity use | Maximizing output and minimizing tap-to-tap time |

| DRI/HBI | Consistent chemistry and inherent carbon for predictable fuel value | Cost-effective energy reduction with operational flexibility |

| High-Quality Scrap | Dense, clean scrap reduces heat loss and flux requirements | Optimizing traditional scrap-based operations |

| Carbon Sources (Coke/Coal) | Fuels exothermic reactions with oxygen, creating foamy slag | Essential for all EAF operations to improve heat transfer |

Ready to optimize your EAF energy efficiency? The right material strategy is key to reducing costs and boosting productivity. KINTEK specializes in providing high-quality lab equipment and consumables for metallurgical analysis, helping you precisely monitor and control your EAF charge materials. Contact us today to discuss how our solutions can support your energy-saving goals. Get in touch with our experts to enhance your steelmaking process.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation