The most common precursor for synthesizing high-quality, large-area graphene via chemical vapor deposition (CVD) is methane (CH4). This simple hydrocarbon gas serves as the carbon source, breaking down at high temperatures to supply the carbon atoms that assemble into the graphene lattice on a catalyst surface.

While methane is the essential carbon source, successful graphene synthesis depends on a precise interplay between the precursor, a metal catalyst, carrier gases, and a highly controlled environment. The precursor is just one piece of a more complex system.

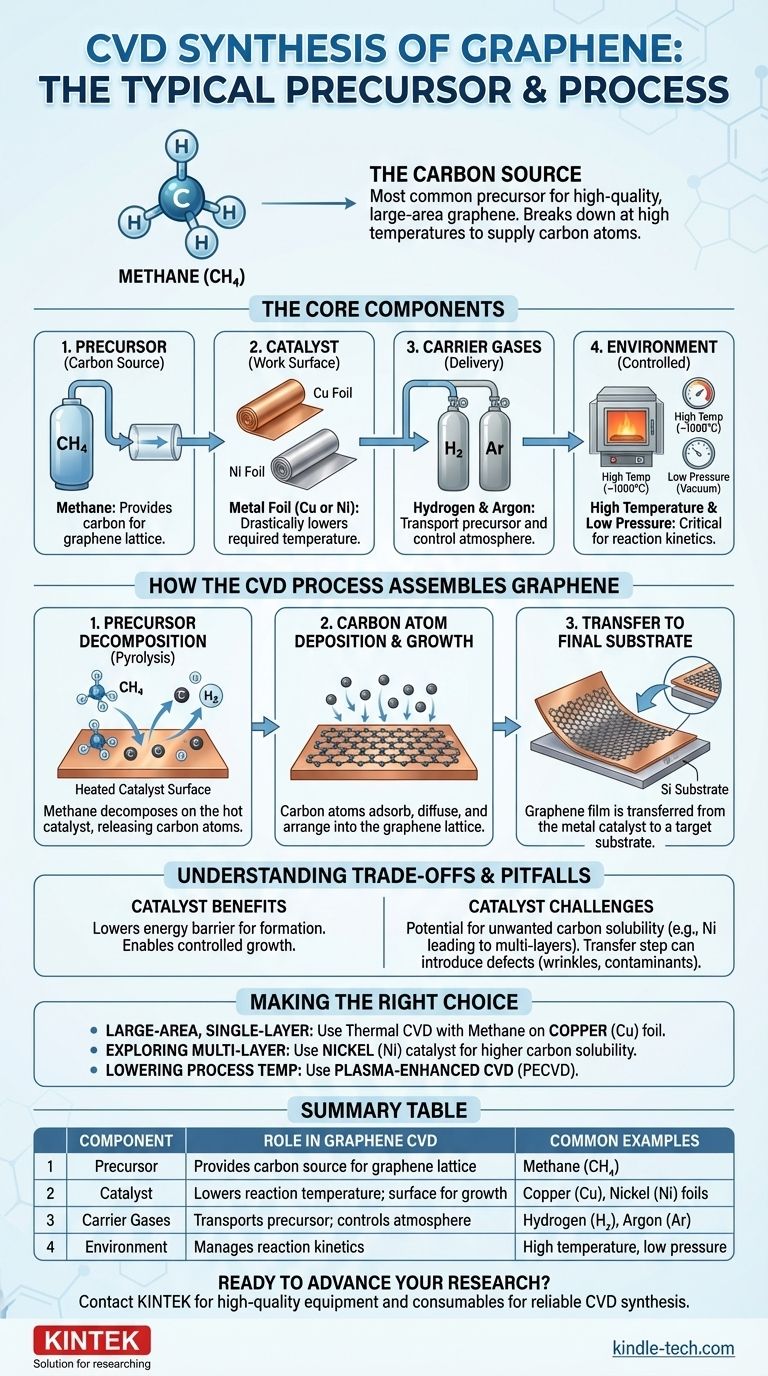

The Core Components of Graphene CVD

To understand the role of the precursor, you must first understand the complete system. Graphene CVD is a "bottom-up" assembly process requiring several key elements to work in harmony.

The Carbon Source (Precursor)

The precursor is the raw material that provides the carbon. Methane is favored for its simplicity and the ability to control the reaction, leading to high-quality, single-layer graphene.

The Catalyst (The Work Surface)

A catalyst is essential. It provides a surface for the reaction to occur and drastically lowers the required temperature from an impractical 2500°C to a more manageable range.

Common catalysts are metal foils, most notably copper (Cu) or nickel (Ni).

The Carrier Gases (The Delivery System)

Gases like hydrogen (H2) and argon (Ar) are used as carriers. They transport the methane precursor into the reaction chamber and help maintain the proper atmospheric pressure and environment for growth.

The Environment (Temperature and Pressure)

The entire process takes place in a furnace under high temperatures and very low pressures. This controlled environment is critical for managing the reaction kinetics and ensuring the quality of the final graphene film.

How the CVD Process Assembles Graphene

The synthesis of graphene via CVD is a multi-step process governed by transport kinetics and surface chemistry.

Step 1: Precursor Decomposition (Pyrolysis)

The methane gas precursor is introduced into the hot furnace. When it comes into contact with the heated catalyst surface (e.g., copper foil), it undergoes pyrolysis, or thermal decomposition.

This process must occur on the catalyst's surface (a heterogeneous reaction) to be effective. If methane breaks down in the gas phase away from the surface, it forms unwanted carbon soot that degrades the quality of the graphene film.

Step 2: Carbon Atom Deposition and Growth

Once freed from the methane molecules, individual carbon atoms adsorb onto the hot catalyst surface. These atoms then diffuse across the surface and arrange themselves into the characteristic hexagonal lattice structure of graphene.

Step 3: Transfer to a Final Substrate

After the growth is complete and the system has cooled, the graphene film exists as a single atomic layer on top of the metal foil. To be used in applications, it must be carefully transferred from the metal catalyst to a target substrate, such as silicon or glass.

Understanding the Trade-offs and Pitfalls

While CVD is a powerful method for producing large-area graphene, it is not without its challenges. The components that make it work also introduce potential complications.

The Necessity of a Catalyst

The primary reason for using a catalyst is to lower the immense energy barrier required for graphene formation. Without a catalyst, the reaction rate is highly sensitive to temperature, making the process almost impossible to control.

The Downsides of Catalysts

Introducing a metal catalyst can lead to its own issues. Different metals have different carbon solubilities. Nickel, for example, can dissolve carbon atoms, which can lead to uncontrolled deposition and the formation of multiple graphene layers during the cooling phase.

The Post-Growth Transfer Challenge

The final transfer step is a significant source of defects. Moving a film that is only one atom thick without introducing wrinkles, tears, or contaminants is a major engineering challenge that can impact the final quality of the graphene.

Making the Right Choice for Your Goal

The specific parameters of the CVD process are chosen based on the desired outcome for the graphene film.

- If your primary focus is large-area, single-layer films: Thermal CVD using methane on a copper (Cu) foil is the most common and well-established method.

- If your primary focus is exploring multi-layer growth: Using a nickel (Ni) catalyst can be advantageous due to its higher carbon solubility, though it requires more precise control over the cooling process.

- If your primary focus is lowering the process temperature: Plasma-Enhanced CVD (PECVD) is an alternative that uses plasma to help decompose the precursor gas, reducing the need for extremely high furnace temperatures.

Ultimately, mastering graphene synthesis is about understanding how these individual components—precursor, catalyst, and environment—collectively determine the final material's quality.

Summary Table:

| Component | Role in Graphene CVD | Common Examples |

|---|---|---|

| Precursor | Provides carbon source for graphene lattice | Methane (CH₄) |

| Catalyst | Lowers reaction temperature; surface for growth | Copper (Cu), Nickel (Ni) foils |

| Carrier Gases | Transports precursor; controls atmosphere | Hydrogen (H₂), Argon (Ar) |

| Environment | Manages reaction kinetics | High temperature, low pressure |

Ready to advance your materials research with high-quality graphene? The precise control of precursors, catalysts, and process parameters is critical for success. KINTEK specializes in providing the lab equipment and consumables needed for reliable CVD synthesis. Whether you are developing new electronic materials or advanced coatings, our expertise can help you achieve consistent, high-quality results. Contact our experts today to discuss how we can support your specific laboratory needs.

Visual Guide

Related Products

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Large Vertical Graphite Vacuum Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What are the environmental issues with diamond mining? Uncover the True Ecological and Human Cost

- Will CVD diamond change color? Discover the Science of Permanent, Stable Color

- What are some ethical issues with diamond mining? Uncover the Hidden Costs of Your Gemstone

- What are the raw materials for CVD diamonds? A seed, a gas, and the science of crystal growth.

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods