In essence, a burnout oven is a specialized, high-temperature furnace designed for one primary purpose: to completely eliminate a pattern model from a refractory mold, creating a perfect, hollow cavity for casting. This procedure, known as the burnout cycle, is the critical intermediate step in investment casting, a process used in industries ranging from jewelry and dentistry to aerospace and art. It ensures the pattern vanishes without a trace, leaving a clean mold ready for molten material.

The function of a burnout oven goes far beyond simple melting. It executes a precise, multi-stage thermal program to remove the pattern, cure the mold, and prepare it for casting—all while preventing cracks and eliminating residue that would ruin the final product.

The Role of Burnout in Investment Casting

Investment casting is a process for creating complex metal parts with high detail. The burnout oven is the heart of this process, transforming a pattern-filled mold into a ready-to-use vessel.

The Initial State: The Investment Flask

The process begins with a master pattern, often made of wax or a special 3D-printable "castable" resin. This pattern is encased in a plaster-like slurry called investment. Once hardened, this forms a solid block (the "flask") with the pattern trapped inside.

The Burnout Cycle: More Than Just Heat

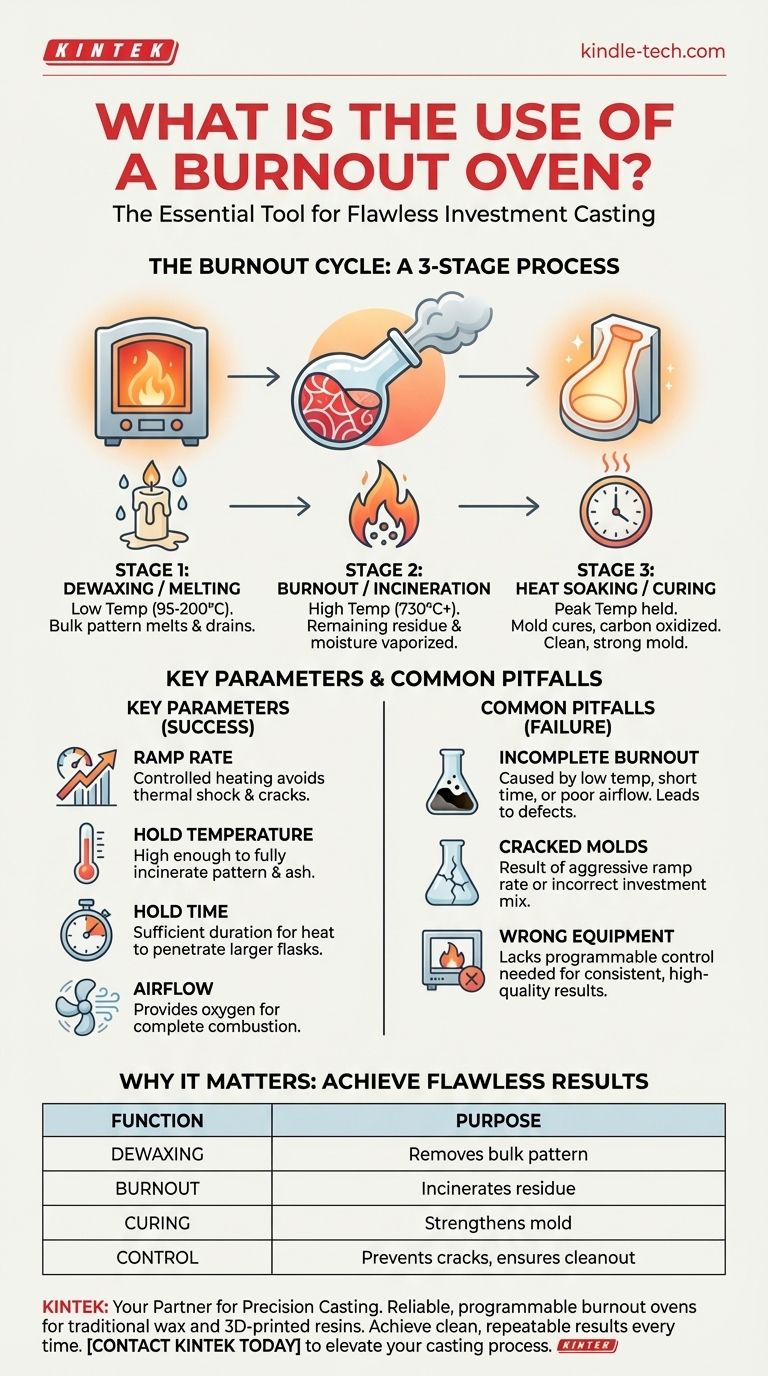

The flask is placed upside down in the burnout oven to begin a carefully controlled heating schedule. This isn't just about cranking up the heat; it's a multi-stage process.

- Dewaxing/Melting: At lower temperatures (around 200-400°F / 95-200°C), the bulk of the wax pattern melts and drains out of the flask.

- Burnout/Incineration: As the temperature ramps up significantly (often to 1350°F / 730°C or higher), any remaining wax or resin residue is completely incinerated. This stage also burns away any residual moisture from the investment itself.

- Heat Soaking/Curing: The oven holds the flask at this peak temperature for several hours. This "heat soaking" ensures the heat fully penetrates the mold, all carbon residue is oxidized and removed, and the investment material is properly cured and strengthened.

Why a Clean Burnout is Essential

The goal is to create a perfect negative space inside the mold. Any ash, carbon residue, or moisture left behind will cause casting defects like porosity, rough surfaces, or incomplete filling when the molten metal is introduced.

Key Parameters of a Successful Burnout

A modern burnout oven allows for precise control over the heating cycle. Each parameter is critical for a successful outcome.

Ramp Rate

The ramp rate is the speed at which the oven's temperature increases. If the temperature rises too quickly, the rapid expansion of the wax pattern and escaping steam can cause thermal shock, cracking the investment mold and ruining the cast before it even starts.

Hold Temperature

The peak temperature must be high enough to completely incinerate the pattern material. Traditional waxes burn out cleanly around 1350°F (730°C). However, many modern 3D-printed resins require different, often higher, temperatures and more complex schedules to prevent ash residue.

Hold Time

This is the duration the oven remains at its peak temperature. The hold time depends on the size and thickness of the flask. A larger flask requires a longer hold time to ensure heat penetrates to its core and fully eliminates all residue.

Airflow and Ventilation

Complete incineration requires oxygen. A proper burnout oven facilitates airflow to supply fresh oxygen to the chamber and vent the fumes produced by the burning pattern. Insufficient airflow is a primary cause of incomplete burnout, as it starves the chemical reaction.

Understanding the Common Pitfalls

Deviating from the correct burnout process is the most frequent source of failed casts. Understanding these pitfalls is key to troubleshooting.

Incomplete Burnout

This is the most common failure. It is caused by a temperature that is too low, a hold time that is too short, or poor ventilation. The result is carbon residue in the mold cavity, leading to a porous, contaminated, or rough-surfaced final part.

Cracked Investment Molds

Cracks are almost always a result of heating the flask too quickly (an aggressive ramp rate). The pattern expands faster than the investment can accommodate, fracturing the mold. It can also be caused by an incorrect water-to-powder ratio when mixing the investment.

Choosing the Wrong Equipment

While a basic kiln can generate heat, a true burnout oven offers programmable control. The ability to set specific ramp rates, hold temperatures, and hold times is not a luxury—it is essential for achieving the repeatable, high-quality results demanded by professional jewelry, dental, and industrial applications.

Making the Right Choice for Your Goal

Your burnout strategy must align with your pattern material and desired outcome.

- If your primary focus is traditional wax casting: A standard, single-plateau burnout schedule with a peak temperature around 1350°F (730°C) is your reliable baseline.

- If your primary focus is casting 3D-printed resins: You must follow the specific, often multi-stage, burnout schedule recommended by the resin manufacturer, as resins expand differently and require more careful management to burn out cleanly.

- If you are experiencing casting defects: First, re-evaluate your burnout cycle. Ensure your hold time is sufficient for your flask size and that the oven has adequate airflow, as incomplete burnout is the most common cause of failure.

Ultimately, mastering the burnout oven is mastering the foundation upon which every successful cast is built.

Summary Table:

| Key Burnout Oven Function | Purpose |

|---|---|

| Dewaxing/Melting | Removes bulk pattern material (wax/resin) |

| Burnout/Incineration | Incinerates residue at high temperatures |

| Heat Soaking/Curing | Cures and strengthens the investment mold |

| Precise Temperature Control | Prevents mold cracks and ensures complete burnout |

| Adequate Airflow | Provides oxygen for complete incineration of residues |

Achieve flawless casting results with the right equipment.

A properly executed burnout cycle is the foundation of a successful cast, eliminating defects like porosity and rough surfaces. KINTEK specializes in lab equipment and consumables, providing reliable, programmable burnout ovens designed for the precise needs of jewelers, dental technicians, and industrial casting professionals.

Let us help you master this critical step. Our expertise ensures you get the right oven for your specific pattern materials—whether traditional wax or modern 3D-printed resins—guaranteeing clean, repeatable results every time.

Contact KINTEK today to discuss your burnout oven requirements and elevate your casting process.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What temperature is porcelain fired at? A Guide to Precise Dental Firing Cycles

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- Why are porcelain fired under vacuum? To Eliminate Porosity for Superior Strength & Translucency

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API