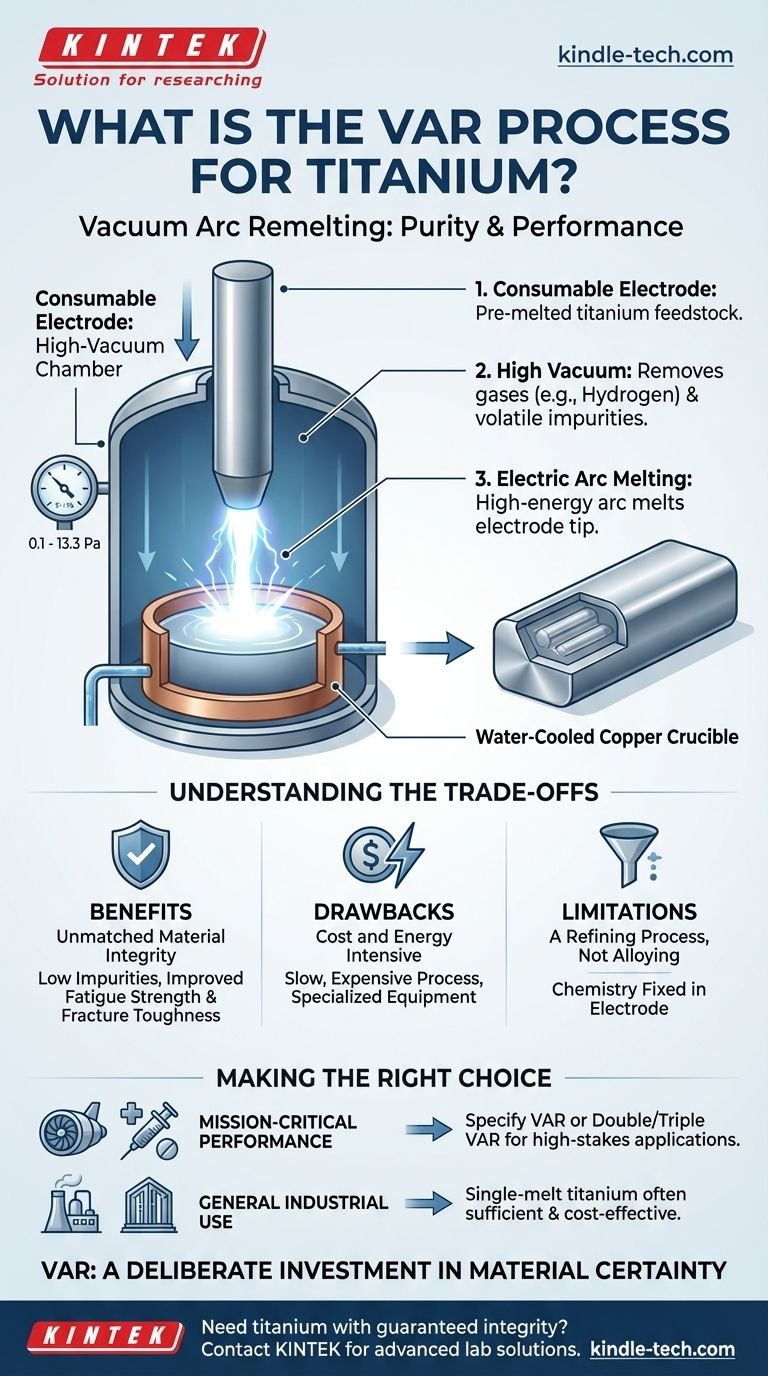

At its core, Vacuum Arc Remelting (VAR) is a secondary melting process used to produce highly pure, uniform titanium ingots. It functions by using a high-energy electric arc to remelt a previously formed titanium cylinder, known as a consumable electrode, all within a high-vacuum chamber. The molten metal then solidifies in a water-cooled copper mold, resulting in a refined final product with superior mechanical properties.

The true purpose of VAR is not simply to melt titanium, but to purify and homogenize it. By remelting under a vacuum, the process removes undesirable gases and volatile elements, while controlled solidification creates an exceptionally clean and consistent internal structure essential for high-performance applications.

How the VAR Process Achieves Purity

The effectiveness of VAR lies in its systematic approach to refining the metal. Each stage is designed to remove specific impurities and control the final structure of the ingot.

The Consumable Electrode

The process begins with a "consumable electrode." This is not raw material, but a large, compacted cylinder made of titanium sponge and any required alloying elements that has already been melted once. This electrode acts as the feedstock for the refining process.

The Role of the High Vacuum

The entire process takes place under a high vacuum (typically 0.1 to 13.3 Pascals). This vacuum environment is critical; as the metal melts, the lack of atmospheric pressure allows trapped gases like hydrogen and other volatile impurities to be pulled out of the liquid metal.

The Electric Arc and Controlled Melting

A DC power supply creates a powerful electric arc between the bottom of the electrode and a small amount of starter material in the crucible below. The intense heat from this arc, which can exceed the melting point of titanium, progressively melts the tip of the electrode.

Progressive Solidification

As the electrode melts, droplets of pure, molten titanium fall into a water-cooled copper crucible. Because the crucible walls are actively cooled, the molten metal begins to solidify immediately upon contact, forming a solid shell. The ingot builds up slowly as more metal melts, solidifying from the bottom up and outside in. This controlled cooling process helps create a fine, uniform grain structure and pushes any remaining non-metallic impurities toward the top of the ingot, which is later cropped off.

Understanding the Trade-offs

VAR is a powerful tool, but it is a specialized one. Understanding its benefits and drawbacks is key to knowing when to specify it.

The Benefit: Unmatched Material Integrity

VAR produces titanium with exceptionally low levels of dissolved gases (especially hydrogen) and non-metallic inclusions. This cleanliness dramatically improves the material's fatigue strength and fracture toughness, which is non-negotiable for critical components.

The Drawback: Cost and Energy

This is an energy-intensive, slow, and expensive process. The specialized equipment and precise control required add significant cost compared to primary melting methods. For this reason, VAR is reserved for applications where performance justifies the expense.

The Limitation: A Refining Process, Not an Alloying One

VAR is primarily designed to clean up and homogenize an existing alloy composition. The chemistry of the metal is largely fixed in the consumable electrode. It is not a practical method for making significant changes to an alloy's composition during the remelt itself.

Making the Right Choice for Your Goal

Deciding whether to specify a VAR-processed material depends entirely on the demands of your application and the consequences of material failure.

- If your primary focus is mission-critical performance: Specify VAR or even Double/Triple VAR for applications like rotating jet engine parts, critical airframe structures, or permanent medical implants where failure could be catastrophic.

- If your primary focus is general industrial use: A less expensive, single-melt titanium grade is often sufficient and more cost-effective for applications like chemical processing equipment, architectural elements, or non-structural components.

Ultimately, the VAR process represents a deliberate investment in material certainty, ensuring the highest possible integrity for the most demanding environments.

Summary Table:

| Process Stage | Key Function | Outcome |

|---|---|---|

| Consumable Electrode | Acts as feedstock | Provides pre-alloyed material for refining |

| High Vacuum Environment | Removes gases (e.g., hydrogen) | Significantly reduces dissolved impurities |

| Electric Arc Melting | Melts the electrode tip | Creates a controlled pool of molten metal |

| Progressive Solidification | Cools metal in water-cooled mold | Forms a fine, uniform grain structure |

Need titanium with guaranteed integrity for your critical components? The VAR process is essential for achieving the purity and homogeneity required in aerospace, medical, and other high-stakes industries. KINTEK specializes in providing the advanced lab equipment and consumables needed to support and analyze materials produced with these sophisticated melting techniques. Contact our experts today to discuss how we can help you meet your most demanding material specifications.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why is a high-precision furnace necessary for T91 steel heat treatment? Ensure 1050°C and 770°C Thermal Stability

- What is the purpose of using a vacuum oven for sulfide battery electrodes? Optimize Drying & Protect Material Integrity

- What is the temperature of the arc in an electric arc furnace? Harnessing Heat Hotter Than the Sun

- Which is better low pressure casting or vacuum permanent mold casting? Choosing the Right Process for Your Component

- What is the difference between vacuum cast and vacuum form? Choose the Right Process for Your Prototype

- What kind of energy does pyrolysis generate? Converting Waste into Valuable Fuels

- What is the application of quenching effect? Achieve Superior Hardness and Strength in Materials

- What is the function of high-temperature vacuum furnaces in EUROFER steel development for nuclear fusion reactors?