In essence, a vertical ball mill operates by using a central, high-speed agitator to stir grinding media (typically ceramic or steel balls) within a stationary chamber. This forceful agitation creates a vortex of moving media, which grinds the material through intense, continuous shearing and compressive forces. Unlike traditional mills that rely on gravity, this method actively imparts energy directly into the grinding process.

The critical distinction is that a vertical ball mill is a type of stirred or agitated media mill. Its principle is not based on the tumbling and cascading action seen in horizontal mills, but on a powered shaft creating a high-energy grinding field for more efficient fine grinding.

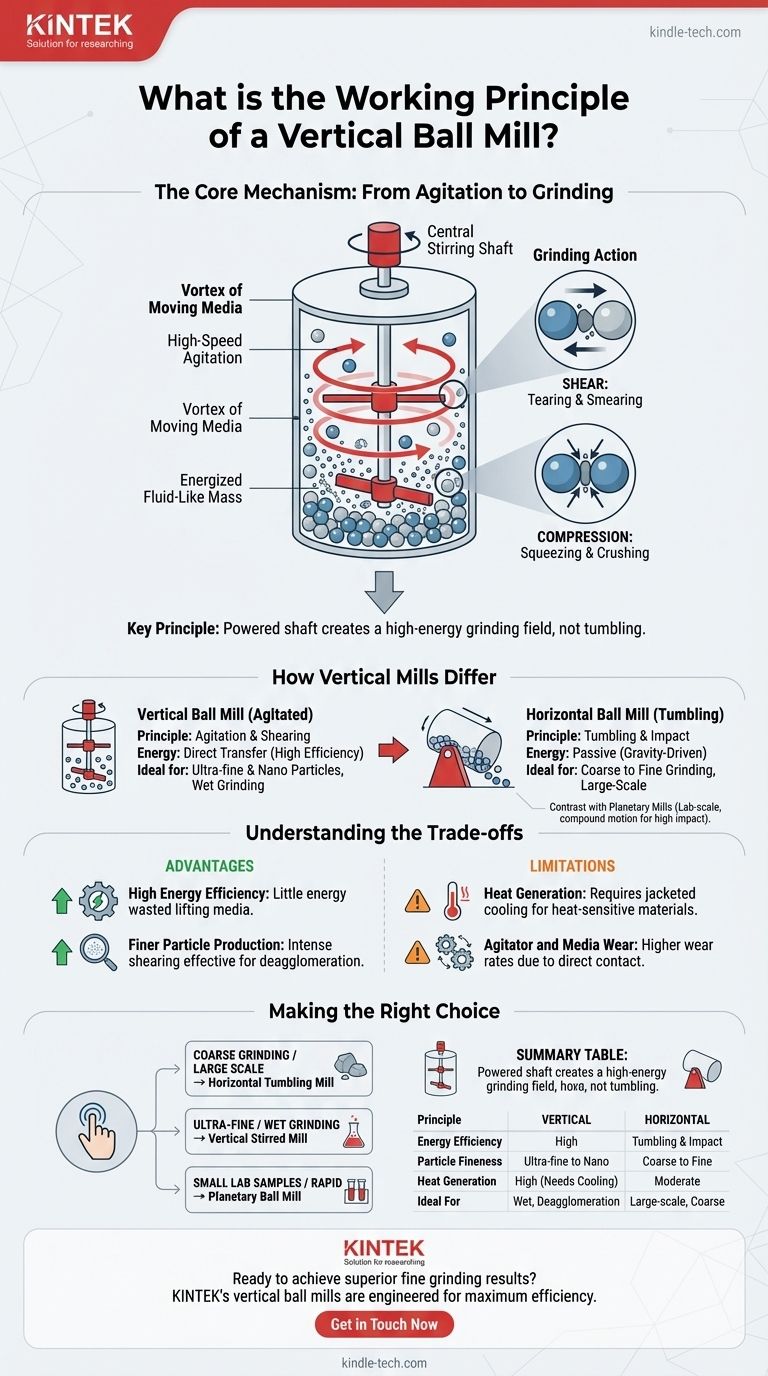

The Core Mechanism: From Agitation to Grinding

The working principle of a vertical ball mill, often called an attritor mill, is a direct and forceful process. Each component plays a precise role in converting rotational energy into grinding power.

The Central Stirring Shaft

At the heart of the mill is a vertical shaft equipped with arms or discs. This agitator extends down into the grinding chamber, which is filled with the grinding media and the material to be processed. The chamber itself does not rotate.

Creating the Grinding Vortex

When the shaft rotates, its arms transfer kinetic energy directly to the grinding balls. This forces the media into a rapid, swirling motion, or vortex. The entire charge of media becomes an energized, fluid-like mass.

The Grinding Action: Shearing and Compression

The grinding effect is achieved through the intense interactions between the moving balls. As material gets caught between the rapidly moving media, it is subjected to two primary forces:

- Shear: The balls move past each other at different velocities, creating a powerful tearing and smearing action.

- Compression: Material is continuously squeezed and crushed in the countless pinch points between the balls.

This constant, high-frequency grinding is fundamentally different from the random, heavy impacts of a tumbling mill.

How Vertical Mills Differ from Other Designs

Understanding what a vertical mill is not helps clarify its unique principle. The term "ball mill" is often used broadly, but the mechanisms vary significantly between designs.

Contrast with Horizontal (Tumbling) Mills

A traditional horizontal ball mill is a rotating cylinder. As it turns, the grinding balls are lifted up the side of the cylinder and then cascade and tumble back down, crushing the material through impact and attrition. This process is passive and driven by gravity and rotation speed.

Contrast with Planetary Mills

A planetary ball mill is a high-energy lab-scale device. Grinding jars are mounted on a large "sun wheel" and rotate on their own axis in the opposite direction of the wheel. This compound motion creates extremely high impact forces, but it is typically used for small sample batches, not the larger-scale production of a vertical mill.

Understanding the Trade-offs

The agitated media principle provides distinct advantages but also introduces specific operational considerations.

Advantage: High Energy Efficiency

Because energy is transferred directly from the agitator to the media, very little is wasted lifting the entire media charge against gravity. This makes vertical mills highly efficient, especially for producing very fine or nano-sized particles.

Advantage: Finer Particle Production

The intense shearing action is exceptionally effective at deagglomeration and reducing materials to a much finer size than is typically achievable in a conventional tumbling mill.

Limitation: Heat Generation

The high energy input generates significant heat within the grinding chamber. For heat-sensitive materials, this requires the use of a jacketed cooling tank and careful temperature control to prevent product degradation.

Limitation: Agitator and Media Wear

The direct, high-intensity contact between the agitator arms and the media results in higher wear rates compared to a tumbling mill. This is a key maintenance and operational cost factor to consider.

Making the Right Choice for Your Application

Selecting the correct milling technology depends entirely on your material properties and desired final particle size.

- If your primary focus is coarse grinding or large-scale primary reduction: A horizontal tumbling mill is often the more robust and cost-effective choice.

- If your primary focus is achieving ultra-fine particles or efficient wet grinding: A vertical stirred mill is the superior technology due to its high-energy shearing action.

- If your primary focus is rapid, high-energy grinding of small lab samples: A planetary ball mill provides the necessary impact energy in a compact format.

Understanding the core principle—agitation versus tumbling—is the key to selecting the milling technology that will most effectively achieve your desired particle size.

Summary Table:

| Feature | Vertical Ball Mill | Horizontal Ball Mill |

|---|---|---|

| Principle | Agitation & Shearing | Tumbling & Impact |

| Energy Efficiency | High (Direct energy transfer) | Lower |

| Particle Fineness | Ultra-fine to Nano | Coarse to Fine |

| Heat Generation | High (Requires cooling) | Moderate |

| Ideal For | Wet grinding, deagglomeration | Large-scale, coarse grinding |

Ready to achieve superior fine grinding results for your laboratory?

KINTEK's vertical ball mills are engineered for maximum efficiency and precise particle size control. Whether you're working on advanced materials, pharmaceuticals, or ceramics, our equipment delivers the intense shearing action you need.

Contact our experts today to find the perfect milling solution for your specific application. Let's optimize your process together!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What affects ball mill efficiency? Optimize Grinding Speed, Media, and Material for Peak Performance

- What is the primary function of the grinding process in LiCoO2/LSPS mixtures? Optimize Solid-State Battery Conductivity

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the preventive maintenance of ball mill? Ensure Maximum Uptime and Reliability