In materials analysis, the X-ray Fluorescence (XRF) pressed pellet method is a fundamental technique for preparing solid samples. The process involves grinding a sample into a fine powder, mixing it with a binding agent, and then using a hydraulic press to compress this mixture into a dense, solid disc suitable for analysis.

The pressed pellet method is a fast and cost-effective way to prepare samples for XRF, but its accuracy can be limited by physical and mineralogical effects that are better managed by the alternative fusion method.

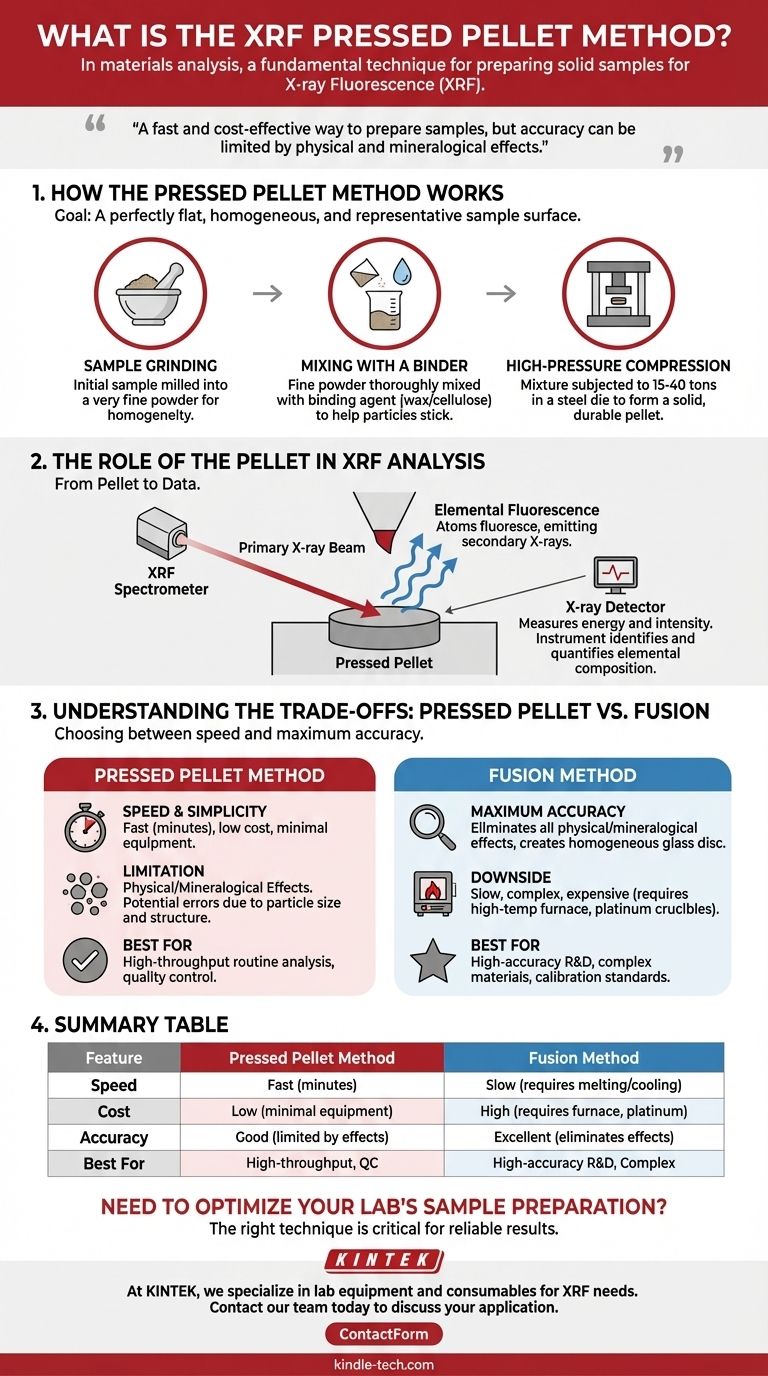

How the Pressed Pellet Method Works

The goal of any XRF sample preparation is to present a perfectly flat, homogeneous, and representative sample surface to the analyzer's X-ray beam. The pressed pellet method achieves this through a straightforward mechanical process.

Step 1: Sample Grinding

The initial sample is first milled or ground into a very fine powder. This step is critical for ensuring the sample is as homogeneous as possible, which improves the reproducibility of the analysis.

Step 2: Mixing with a Binder

This fine powder is then thoroughly mixed with a binding agent, such as a wax or cellulose-based powder. The binder has a simple but essential job: it acts as a glue to help the sample particles stick together under pressure.

Step 3: High-Pressure Compression

The powder-binder mixture is poured into a cylindrical steel die. The die is then placed in a hydraulic press, where it is subjected to immense pressure, typically between 15 and 40 tons, to form a solid, durable pellet.

The Role of the Pellet in XRF Analysis

Once prepared, the pellet provides an ideal physical form for the XRF instrument to analyze. The quality of the pellet directly impacts the quality of the final analytical result.

From Pellet to Data

The prepared pellet is placed inside the XRF spectrometer. The instrument emits a primary X-ray beam that strikes the flat surface of the pellet.

Elemental Fluorescence

This energy causes the atoms of each element within the sample to fluoresce, emitting their own characteristic secondary X-rays.

Detection and Calculation

An X-ray detector inside the analyzer measures the energy and intensity of these secondary X-rays. By processing this data, the instrument can accurately identify and quantify the elemental composition of the original sample.

Understanding the Trade-offs: Pressed Pellet vs. Fusion

The pressed pellet method is one of two primary ways to prepare solid samples for XRF. The other is the fusion method, and choosing between them depends entirely on your analytical requirements.

The Case for Pressed Pellets: Speed and Simplicity

The main advantage of the pressed pellet technique is its speed and low cost. It requires minimal equipment and can be performed quickly, making it ideal for high-throughput environments like quality control labs where rapid results are essential.

The Limitation: Physical Effects

The accuracy of the pressed pellet method can be compromised by "particle size effects" and "mineralogical effects." Different-sized particles or elements bound in different mineral structures can fluoresce unevenly, introducing potential errors into the final measurement.

The Fusion Alternative: Maximum Accuracy

The fusion method overcomes these limitations. It involves dissolving the sample powder at high temperature in a molten salt (a flux) and then cooling the mixture into a perfectly homogeneous glass disc. This process completely eliminates all particle size and mineralogical effects.

The Downside of Fusion: Cost and Complexity

While more accurate, fusion is a slower, more complex, and more expensive process. It requires specialized high-temperature furnaces and expensive platinum crucibles, making it better suited for research, methods development, and applications demanding the highest possible accuracy.

Choosing the Right Method for Your Goal

Selecting the correct sample preparation technique is crucial for generating reliable data. Your choice should be a direct reflection of your analytical needs for speed, accuracy, and cost.

- If your primary focus is rapid, routine analysis for process control: The pressed pellet method is the superior choice for its speed and cost-effectiveness.

- If your primary focus is high-accuracy analysis, creating calibration standards, or analyzing geologically complex materials: The fusion method is required to eliminate physical effects and achieve the most precise results.

Ultimately, understanding the strengths and limitations of each technique empowers you to produce the most dependable data for your specific application.

Summary Table:

| Feature | Pressed Pellet Method | Fusion Method |

|---|---|---|

| Speed | Fast (minutes) | Slow (requires melting/cooling) |

| Cost | Low (minimal equipment) | High (requires furnace, platinum crucibles) |

| Accuracy | Good, but limited by particle/mineral effects | Excellent (eliminates physical/mineralogical effects) |

| Best For | High-throughput routine analysis, quality control | High-accuracy R&D, complex materials, calibration standards |

Need to optimize your lab's sample preparation? The right technique is critical for reliable results. At KINTEK, we specialize in lab equipment and consumables for all your XRF needs. Whether you require robust hydraulic presses for pellet preparation or are exploring fusion for maximum accuracy, our experts can help you select the ideal solution for your laboratory's throughput and accuracy goals.

Contact our team today to discuss your application and ensure your analyses are built on a solid foundation.

Visual Guide

Related Products

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- What is XRF in quantitative analysis? Achieve Precise Elemental Concentration Measurements

- How do you make XRF pellets? A 4-Step Guide to Flawless Sample Preparation

- What is the function of the filter press? Achieve Efficient Solid-Liquid Separation & Sludge Dewatering

- How pressed powder pellets are prepared? Master the Foundation for Reliable Analytical Data

- What role does a laboratory hydraulic press and specialized mold play in zirconium alloys? Ensuring High-Performance Green Body Production

- How do you make KBr pellets? Master the Art of Creating Clear FTIR Discs for Accurate Analysis

- What materials are being analyzed by XRF? Discover Its Versatility for Elemental Analysis

- Can you use a hydraulic press for forging? Power, Precision, and Deep Deformation