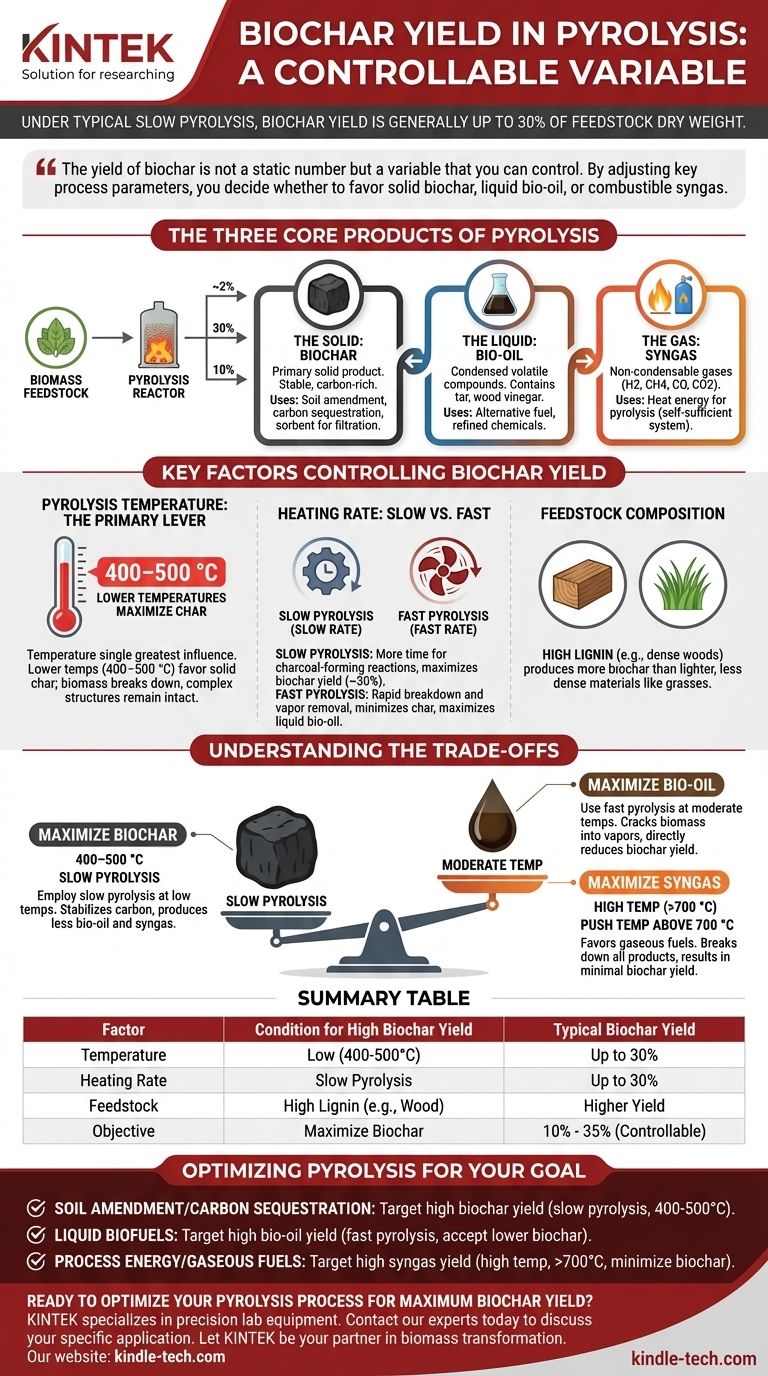

Under typical slow pyrolysis conditions, the yield of biochar is generally up to 30% of the initial feedstock's dry weight. This figure, however, is not a fixed constant. It is the outcome of a controlled thermal process where the final distribution of products—solid, liquid, and gas—is deliberately manipulated.

The yield of biochar is not a static number but a variable that you can control. By adjusting key process parameters, primarily temperature and heating rate, you are essentially deciding whether to favor the production of solid biochar, liquid bio-oil, or combustible syngas.

The Three Core Products of Pyrolysis

Pyrolysis is a process of thermal decomposition in the absence of oxygen. It doesn't destroy matter but rather transforms a single input (biomass) into three distinct and valuable outputs. Understanding this distribution is key to understanding yield.

The Solid: Biochar

This is the primary solid product, a stable, carbon-rich material similar to charcoal. Its uses range from agricultural soil amendment and carbon sequestration to acting as a sorbent for filtration.

The Liquid: Bio-oil

During the process, volatile compounds are released, cooled, and condensed into a liquid fraction. This is often called pyrolysis oil or bio-oil and can contain components like tar and wood vinegar. It can be used as an alternative fuel or refined into other chemicals.

The Gas: Syngas

This is the non-condensable gas fraction produced during pyrolysis. It contains a mixture of hydrogen, methane, carbon monoxide, and carbon dioxide. This gas is often captured and used to provide the heat energy needed to sustain the pyrolysis reaction itself, creating a self-sufficient system.

Key Factors Controlling Biochar Yield

You can shift the balance between these three products by adjusting the conditions under which pyrolysis occurs. The final biochar yield is a direct result of these choices.

Pyrolysis Temperature: The Primary Lever

Temperature has the single greatest influence on the final product. Different temperature ranges favor different outputs.

Lower temperatures, specifically in the 400–500 °C range, maximize the production of the solid char. At these temperatures, the biomass breaks down, but many of the complex carbon structures remain intact.

Heating Rate: Slow vs. Fast

The speed at which the biomass reaches its target temperature is critical.

A slow heating rate (slow pyrolysis) allows more time for charcoal-forming reactions to occur, maximizing the biochar yield. The "up to 30%" figure is typical for this method.

A fast heating rate (fast pyrolysis) is designed to rapidly break down the biomass and immediately remove the vapors before they can react further. This method minimizes char and maximizes the yield of liquid bio-oil.

Feedstock Composition

The type of biomass used as a feedstock matters. Materials with higher lignin content, such as dense woods, tend to produce more biochar than lighter, less dense materials like grasses. The initial composition dictates the raw ingredients available for conversion.

Understanding the Trade-offs

The core principle of pyrolysis is that you cannot maximize all three outputs simultaneously. Increasing the yield of one product inherently means decreasing the yield of the others.

To Maximize Biochar

You must employ slow pyrolysis at relatively low temperatures (400–500 °C). This stabilizes the carbon in its solid form but produces less bio-oil and syngas.

To Maximize Bio-oil

You must use fast pyrolysis at moderate temperatures. This process cracks the biomass into condensable vapors, but it comes at the direct expense of biochar yield, which can drop significantly.

To Maximize Syngas

Pushing the temperature above 700 °C favors the production of gaseous fuels. This process, often closer to gasification, breaks down not only the original biomass but also the intermediate liquid and solid products, resulting in a minimal biochar yield.

Optimizing Pyrolysis for Your Goal

Your ideal yield depends entirely on your primary objective. By understanding the levers, you can tune the process to meet your specific needs.

- If your primary focus is soil amendment or carbon sequestration: Target a high biochar yield by using slow pyrolysis at temperatures between 400°C and 500°C.

- If your primary focus is producing liquid biofuels: Target a high bio-oil yield using fast pyrolysis, accepting a lower biochar output as a necessary trade-off.

- If your primary focus is generating process energy or gaseous fuels: Target a high syngas yield by operating at high temperatures (above 700°C), which will minimize the solid product.

By treating pyrolysis as a controllable system rather than a fixed process, you can transform biomass into the specific output that holds the most value for your application.

Summary Table:

| Factor | Condition for High Biochar Yield | Typical Biochar Yield |

|---|---|---|

| Temperature | Low (400-500°C) | Up to 30% |

| Heating Rate | Slow Pyrolysis | Up to 30% |

| Feedstock | High Lignin (e.g., Wood) | Higher Yield |

| Objective | Maximize Biochar | 10% - 35% (Controllable) |

Ready to optimize your pyrolysis process for maximum biochar yield?

At KINTEK, we specialize in precision lab equipment for pyrolysis research and development. Whether your goal is high-quality biochar production, bio-oil refinement, or syngas optimization, our reactors and analytical tools provide the control and data you need to achieve your targets efficiently.

Let KINTEK be your partner in biomass transformation. Contact our experts today to discuss your specific application and discover the right equipment for your laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is the process description of pyrolysis? Unlock the Potential of Waste-to-Energy Conversion

- What are the uses of pyrolysis machine? Turn Waste into Fuel, Chemicals, and Soil Amendment

- What is the difference between fast and slow pyrolysis? Choosing the Right Biomass Conversion Process

- Does pyrolysis use a lot of energy? Achieve Net Energy Positive Waste Conversion

- What are the risks of pyrolysis? Key Challenges in Waste-to-Energy Conversion

- Does pyrolysis of plastic produce co2? Unpacking the Emissions of a Circular Technology

- What is the operating temperature of pyrolysis? Master the Key to Biochar, Bio-oil, and Syngas Production

- How does pyrolysis help the environment? Transform Waste into Renewable Energy and Carbon Sequestration