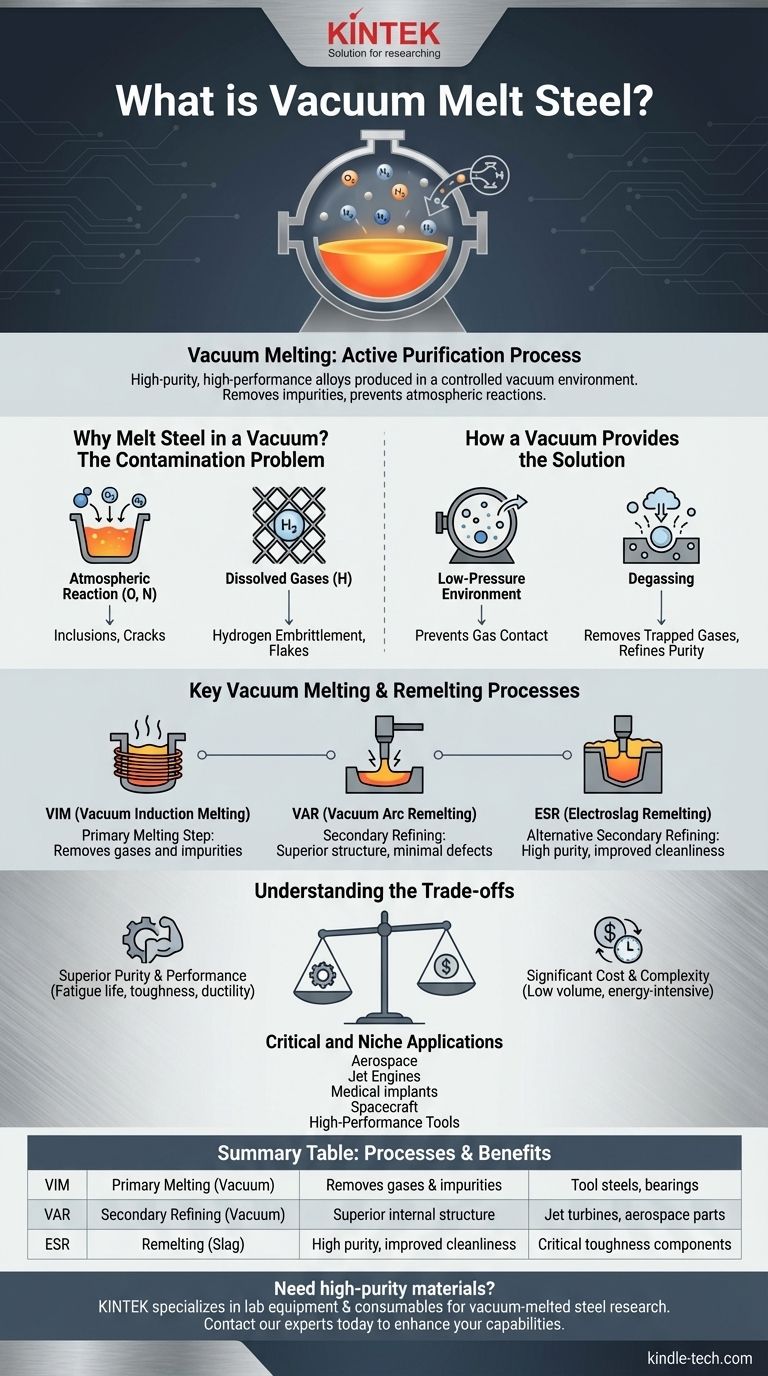

At its core, vacuum melt steel is a category of high-purity, high-performance alloys produced by melting the raw materials inside a vacuum chamber. This controlled environment prevents the molten metal from reacting with atmospheric gases like oxygen and nitrogen, while also pulling out dissolved impurities like hydrogen. The result is a fundamentally "cleaner" steel with superior strength, toughness, and fatigue resistance compared to conventionally produced alloys.

The purpose of vacuum melting is not merely to heat the steel, but to actively purify it. By removing the surrounding atmosphere, you eliminate the root cause of many microscopic defects, producing a material with exceptional and consistent properties demanded by the most critical applications.

Why Melt Steel in a Vacuum? The Problem of Contamination

Standard steelmaking involves melting metal in the open atmosphere or under a protective slag. While effective for most applications, this exposure introduces contaminants that limit the steel's ultimate performance potential.

The Impact of the Atmosphere

When steel is molten, it is highly reactive. Oxygen and nitrogen from the air readily dissolve into the liquid metal, forming microscopic, non-metallic inclusions like oxides and nitrides. These inclusions act as internal stress points, creating initiation sites for cracks and fractures, which reduces the material's toughness and fatigue life.

The Problem of Dissolved Gases

Gases, particularly hydrogen, can become trapped within the steel's atomic structure during the melting process. As the steel cools and solidifies, this trapped hydrogen can lead to a dangerous phenomenon known as hydrogen embrittlement or create internal defects called flakes, severely compromising the material's integrity.

How a Vacuum Provides the Solution

Melting inside a vacuum chamber directly addresses both issues. The low-pressure environment prevents atmospheric gases from ever contacting the molten steel. Furthermore, the vacuum actively pulls dissolved gases (like hydrogen) and other elements with high vapor pressure (like lead or tin) out of the melt, a process known as degassing. This refines the steel to a level of purity that is impossible to achieve with conventional methods.

Key Vacuum Melting and Remelting Processes

The term "vacuum melt" can refer to several distinct but related processes, often used in combination to achieve the highest levels of quality.

Vacuum Induction Melting (VIM)

VIM is typically the primary melting step. High-quality raw materials are placed in a crucible inside a vacuum chamber and melted using an electromagnetic induction furnace. This process produces a very clean initial ingot, which is often sufficient for many high-performance applications.

Vacuum Arc Remelting (VAR)

For the most demanding applications, a VIM ingot undergoes a secondary refining step called VAR. The VIM ingot is used as a giant electrode in a second vacuum chamber. An electric arc is struck at the bottom of the electrode, causing it to progressively melt drop by drop into a water-cooled copper mold below. This process provides an exceptional level of control over solidification, resulting in an even cleaner steel with a superior internal structure and minimal defects. Steels produced this way are often called "double-melted."

Electroslag Remelting (ESR)

Though not a vacuum process, ESR is another common secondary refining method used to produce clean steels. It involves remelting an ingot through a highly reactive molten slag. The slag purifies the steel as it melts through it. While different from VAR, it achieves a similar goal of producing high-purity material and is often considered a competitor to VAR for certain applications.

Understanding the Trade-offs

Choosing a vacuum-melted material is a decision driven by balancing extreme performance requirements against significant cost implications.

The Advantage: Unmatched Purity and Performance

The key benefit is a dramatic improvement in mechanical properties. Vacuum-melted steels exhibit superior fatigue life, impact toughness, and ductility. Their "cleanliness" (the near absence of inclusions) ensures these properties are consistent throughout the material, making performance highly predictable and reliable.

The Disadvantage: Significant Cost and Complexity

Vacuum melting is an expensive, low-volume, and energy-intensive process. The specialized equipment, longer processing times, and stringent quality control measures add substantially to the final cost of the material compared to air-melted steel.

The Result: Critical and Niche Applications

Due to the high cost, vacuum-melted steels are reserved for applications where failure is not an option. This includes aircraft landing gear, turbine discs and blades in jet engines, medical implants, bearings in spacecraft, and ultra-high-performance tool and die steels.

When to Specify Vacuum Melt Steel

Your material choice should be dictated entirely by the performance requirements and operating environment of the final component.

- If your primary focus is extreme reliability and fatigue life: Specify a double-melt (VIM/VAR) steel for mission-critical components like aerospace structural parts or high-RPM engine components.

- If your primary focus is high-performance tooling or bearings: A VIM or ESR steel offers a significant boost in toughness and wear resistance, leading to longer service life and more predictable performance.

- If your primary focus is general structural or commercial use: Conventional air-melted steel provides the necessary performance at a fraction of the cost and is the appropriate choice for the vast majority of applications.

By understanding that vacuum melting is a purification process, you can make an informed decision, ensuring you invest in higher-cost materials only when the application truly demands it.

Summary Table:

| Process | Key Feature | Primary Benefit | Common Applications |

|---|---|---|---|

| VIM (Vacuum Induction Melting) | Primary melting under vacuum | Removes gases and impurities | High-performance tool steels, bearings |

| VAR (Vacuum Arc Remelting) | Secondary refining of VIM ingot | Superior internal structure, minimal defects | Jet engine turbines, aerospace structural parts |

| ESR (Electroslag Remelting) | Remelting through reactive slag | High purity, improved cleanliness | Critical components requiring toughness and reliability |

Need high-purity materials for your most demanding applications? KINTEK specializes in providing the advanced lab equipment and consumables essential for researching and producing vacuum-melted steels. Whether you're developing next-generation aerospace components or medical implants, our solutions support the precision and reliability your work requires. Contact our experts today to discuss how we can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Cold Mounting Machine for Sample Preparation

People Also Ask

- What are the two methods of induction heating? Coreless vs. Channel Furnaces Explained

- How do specialized industrial-grade small melting furnaces address challenges in precision jewelry casting? Expert Guide

- What type of lining is needed for induction furnace? Choose the Right Refractory for Your Metal

- What is the basic principle of induction heating? Fast, Precise, and Contactless Heating Explained

- What is the principle of vacuum arc melting? A Deep Dive into High-Purity Metal Refining

- How can I reduce the power consumption of my induction furnace? Slash Energy Costs with a Holistic Approach

- What is an Inductotherm furnace? Harnessing Electromagnetic Power for Fast, Pure Melting

- What is a direct core type induction furnace? Unmatched Efficiency for High-Volume Metal Melting