In essence, vacuum retorting is a high-temperature process used to extract, purify, or cause chemical reactions in materials within a sealed vessel (a retort) from which the air has been removed. The vacuum environment is the critical element, as it prevents unwanted chemical reactions like oxidation and allows for the precise removal of volatile substances at lower temperatures than would be possible in open air.

The core purpose of vacuum retorting is not merely to heat a material, but to use the absence of air to gain precise control over its chemical transformation, enabling levels of purity and specific reactions that are otherwise unattainable.

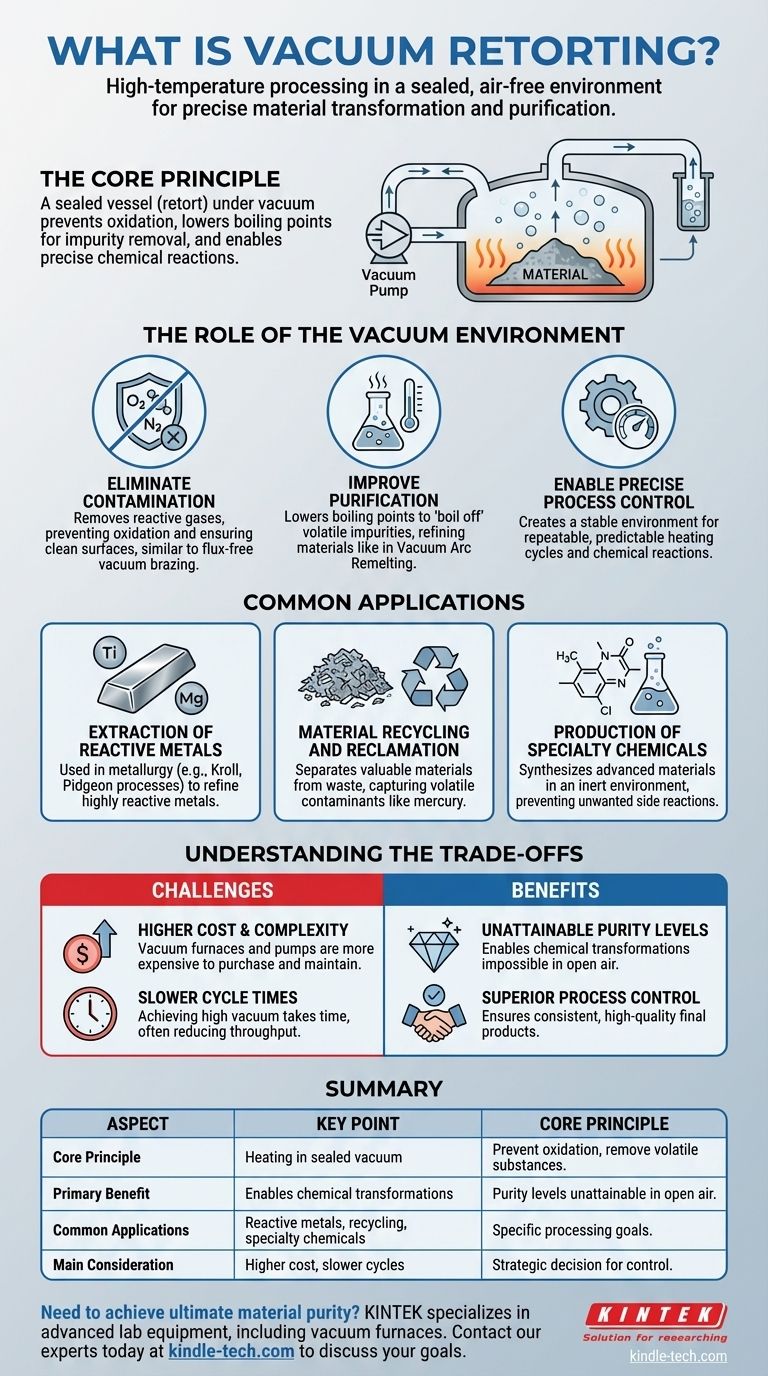

The Role of the Vacuum Environment

While distinct from processes like vacuum brazing or arc remelting, vacuum retorting shares the same fundamental advantages of operating in a controlled, air-free environment. The vacuum itself is a powerful tool for material processing.

To Eliminate Contamination

In any high-temperature process, the presence of air—specifically oxygen and nitrogen—can lead to unwanted chemical reactions.

A vacuum removes these reactive gases. This is crucial for preventing the formation of oxides on material surfaces, ensuring the end product is clean and has the desired chemical properties, much like the flux-free joints achieved in vacuum brazing.

To Improve Purification

A vacuum drastically lowers the boiling point of substances. This principle is leveraged to "boil off" volatile impurities or byproducts from a primary material at manageable temperatures.

This selective removal of unwanted elements is a form of purification. It is conceptually similar to how Vacuum Arc Remelting is used to improve the cleanliness of steels and superalloys by removing impurities under vacuum.

To Enable Precise Process Control

A vacuum creates an exceptionally stable and predictable environment. With atmospheric variables removed, operators gain precise control over the heating and cooling cycles and the chemical reactions taking place.

This level of control ensures that processes are repeatable and that the final product consistently meets tight specifications, minimizing variations and residual stress in the processed material.

Common Applications and Use Cases

Vacuum retorting is not a universal solution but is applied where material purity and chemical control are paramount.

Extraction of Reactive Metals

The process is often used in metallurgy to extract or refine highly reactive metals. For example, the Kroll process for producing titanium and the Pidgeon process for producing magnesium rely on principles of high-temperature vacuum reduction and distillation.

Material Recycling and Reclamation

Vacuum retorting is highly effective for separating valuable materials from waste or contaminated feedstocks. It can be used to remove and capture volatile contaminants like mercury from industrial sludge, leaving behind the cleaned, non-volatile material.

Production of Specialty Chemicals

When synthesizing advanced materials or chemicals, preventing side reactions with the atmosphere is critical. Vacuum retorting provides the inert environment needed to ensure the desired chemical pathway is followed exclusively.

Understanding the Trade-offs

While powerful, vacuum processing introduces specific challenges that must be considered.

Equipment Complexity and Cost

Vacuum furnaces, pumps, and control systems are significantly more complex and expensive to purchase and maintain than standard atmospheric furnaces.

Slower Cycle Times

Achieving and maintaining a high vacuum takes time. The process of pumping down the chamber before heating and backfilling it before cooling adds time to each cycle, often making it a batch process with lower throughput than continuous atmospheric methods.

Material Suitability

The process is not suitable for all materials. Substances with extremely high vapor pressures can overwhelm the vacuum system or be unintentionally removed from the primary material being processed.

Making the Right Choice for Your Goal

Selecting a thermal process requires aligning the method with the intended outcome.

- If your primary focus is high-purity refinement or chemical extraction: Vacuum retorting is a superior choice for removing volatile impurities and preventing oxidation.

- If your primary focus is joining high-precision components: A related process like vacuum brazing is specifically designed for creating clean, strong, and oxide-free joints.

- If your primary focus is simply changing a material's physical properties (e.g., hardening): A standard heat treatment in a controlled gas atmosphere may be a more cost-effective solution.

Ultimately, employing a vacuum is a strategic decision to gain absolute control over a material's chemical environment during thermal processing.

Summary Table:

| Aspect | Key Point |

|---|---|

| Core Principle | Heating materials in a sealed vacuum to prevent oxidation and remove volatile substances. |

| Primary Benefit | Enables chemical transformations and purity levels unattainable in open air. |

| Common Applications | Extraction of reactive metals, material recycling, production of specialty chemicals. |

| Main Consideration | Higher equipment cost and slower cycle times compared to atmospheric processes. |

Need to achieve ultimate material purity?

Vacuum retorting is the key to preventing contamination and enabling precise chemical reactions. KINTEK specializes in advanced lab equipment, including vacuum furnaces, to meet the demanding needs of laboratories in metallurgy, chemistry, and materials science.

Contact our experts today to discuss how our solutions can help you achieve your specific processing goals with reliability and precision.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What conditions does a vacuum sintering furnace provide for the diffusion bonding of titanium? Achieve Isotropic Purity

- What materials are vacuum hardened? Achieve Superior Surface Quality for High-Alloy Steels and Sensitive Metals

- Which method of heat transfer occur in a vacuum? Unlocking the Power of Thermal Radiation

- What is the primary function of a vacuum sintering furnace? Essential Role in High-Purity Ti2AlN Synthesis

- Is brazing flux different to soldering flux? A Guide to Choosing the Right Chemical for Your Joint

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance

- What are the three types of furnaces? Choose the Right Furnace for Your Needs

- What are the core advantages of using an SPS system for nickel-based alloys? Achieve Superior Densification with KINTEK