VAR material is not a specific type of metal, but rather a designation for a standard alloy that has undergone a high-purity refining process called Vacuum Arc Remelting. This secondary melting process is designed to remove imperfections, such as dissolved gases and non-metallic inclusions, from an existing alloy. The result is an exceptionally clean and uniform material with superior mechanical properties compared to its standard, non-remelted counterpart.

The core takeaway is that Vacuum Arc Remelting (VAR) is a purification process, not a material type. It is used to create an ultra-clean version of a known alloy (like steel, titanium, or nickel-based superalloys) for critical applications where material reliability and fatigue resistance are paramount.

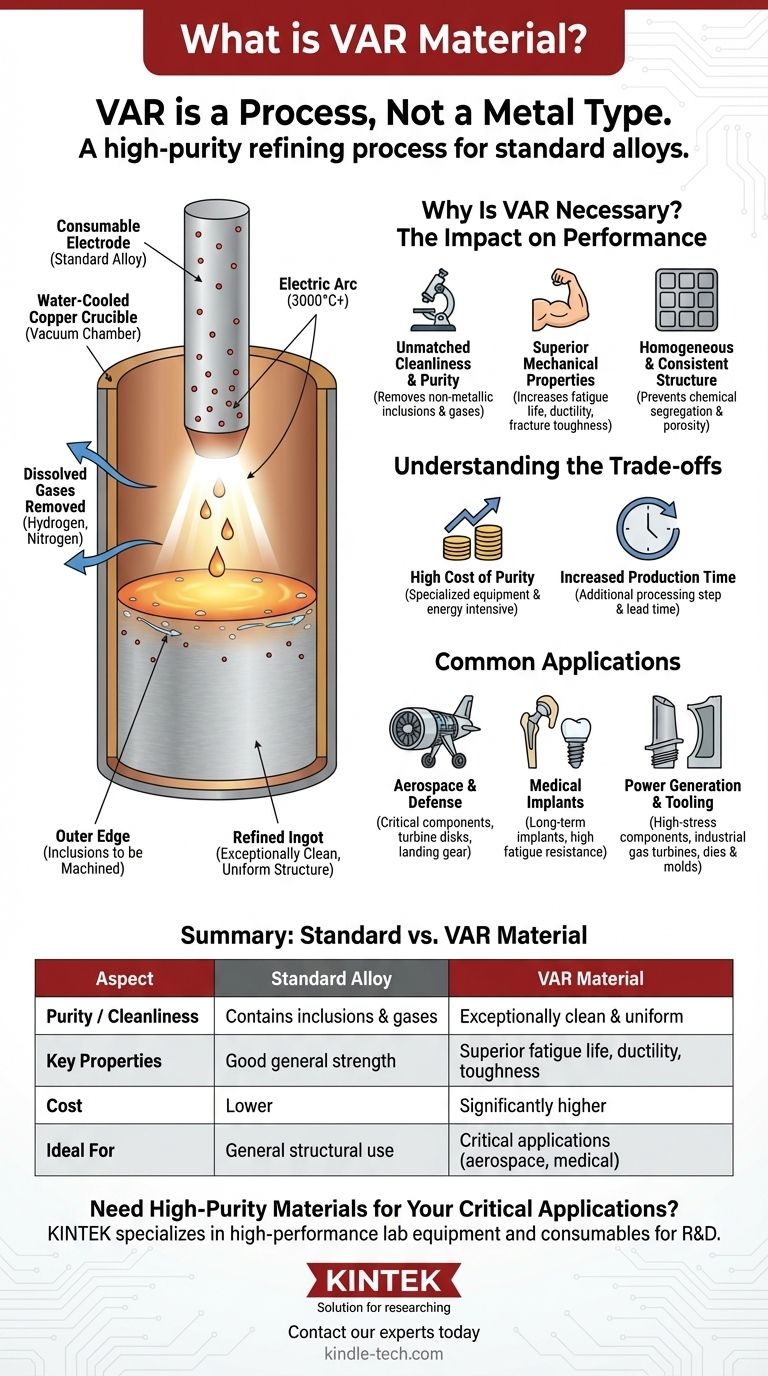

What is Vacuum Arc Remelting (VAR)?

The VAR process refines a solid metal electrode into a new, highly purified ingot. It is a crucial step for manufacturing high-performance materials used in demanding industries.

The Starting Point: A Consumable Electrode

The process begins with a solid cylinder of the alloy to be refined, known as a consumable electrode. This electrode is typically produced through a primary melting method, such as Vacuum Induction Melting (VIM).

The Process: Remelting Under Vacuum

The electrode is placed inside a water-cooled copper crucible within a vacuum chamber. An electric arc is initiated between the bottom of the electrode and a small amount of starter material in the crucible.

The intense heat from the arc (often exceeding 3,000°C) progressively melts the tip of the electrode. As the molten metal drips down, the vacuum environment pulls out dissolved gases like hydrogen and nitrogen.

The Result: A Refined Ingot

The molten metal collects and solidifies in the water-cooled crucible. During this controlled re-solidification, lighter impurities (inclusions) float to the top of the molten pool.

This action pushes imperfections to the outer edge of the new ingot, which can be machined away later. The final product is a chemically homogeneous ingot with a refined grain structure and exceptionally low levels of impurities.

Why Is VAR Necessary? The Impact on Performance

Using a VAR-processed material is a deliberate choice driven by the need for enhanced reliability and specific mechanical properties that standard alloys cannot provide.

Unmatched Cleanliness and Purity

The primary benefit of VAR is achieving "clean" metal. The process significantly reduces or eliminates non-metallic inclusions (like oxides and nitrides) and dissolved gases.

These microscopic imperfections are often the initiation points for cracks and material failure, especially under cyclic loading (fatigue).

Superior Mechanical Properties

By removing these defects, VAR dramatically improves a material's performance. The most notable benefits are a significant increase in fatigue life, ductility, and fracture toughness.

This means the material can withstand more stress cycles and resist crack propagation far better than a conventional air-melted alloy.

A Homogeneous and Consistent Structure

The controlled, directional solidification in the VAR process prevents chemical segregation and eliminates the internal porosity (microscopic voids) common in conventional casting.

This results in a material that is incredibly consistent, ensuring that its mechanical properties are uniform from end to end. Predictability is a key advantage for engineers.

Understanding the Trade-offs

While VAR provides unparalleled material quality, its benefits come at a cost. It is an additional, resource-intensive step in the production chain.

The High Cost of Purity

The VAR process requires specialized equipment, significant electrical energy, and a controlled vacuum environment. This makes VAR materials substantially more expensive than their non-remelted equivalents.

The final cost is a direct reflection of the complexity and energy required to achieve such high levels of purity.

Increased Production Time

Adding a secondary remelting step to the manufacturing workflow naturally increases the overall lead time for the final material.

For applications with tight schedules, this factor must be considered in project planning. The VIM-VAR process, which combines two vacuum melting steps for the highest purity, further extends this timeline.

Common Applications: Where Failure is Not an Option

VAR materials are specified for components in industries where a material failure would have catastrophic consequences.

Aerospace and Defense

This is the largest market for VAR materials. They are used for fracture-critical components like turbine and compressor disks in jet engines, landing gear, and high-strength fasteners.

Medical Implants

The combination of high strength, fatigue resistance, and excellent biocompatibility makes VAR titanium and cobalt-chrome alloys ideal for long-term medical implants such as artificial hips, knees, and dental fixtures.

Power Generation and High-Stress Tooling

VAR superalloys are used for blades in industrial gas turbines. In manufacturing, VAR tool steels are used to create high-performance dies and molds that must withstand extreme pressure and temperature cycles.

Is VAR Material Right for Your Application?

Choosing to specify a VAR-processed material is a decision based on balancing performance requirements against cost.

- If your primary focus is extreme reliability and fatigue life (e.g., aerospace, medical implants): A VAR or VIM-VAR processed material is often a non-negotiable requirement to meet safety and performance standards.

- If your primary focus is general structural use with moderate stress: A standard air-melted alloy or a material refined by a less expensive process like Electroslag Remelting (ESR) may provide a much better cost-performance balance.

- If your primary focus is cost reduction: VAR is almost certainly overkill unless its use is mandated by regulation or you have identified a clear failure mode in a less pure material.

Ultimately, choosing a VAR material is an investment in certainty, ensuring the highest possible material integrity for the most demanding environments.

Summary Table:

| Aspect | Standard Alloy | VAR Material |

|---|---|---|

| Purity / Cleanliness | Contains inclusions & gases | Exceptionally clean & uniform |

| Key Properties | Good general strength | Superior fatigue life, ductility, toughness |

| Cost | Lower | Significantly higher |

| Ideal For | General structural use | Critical applications (aerospace, medical) |

Need High-Purity Materials for Your Critical Applications?

VAR-processed materials are essential for components where failure is not an option. KINTEK specializes in providing high-performance lab equipment and consumables, including materials for research and development in demanding fields.

Our expertise ensures you get the right materials for applications in aerospace, medical implants, and advanced manufacturing, guaranteeing the reliability and performance your projects demand.

Contact our experts today to discuss how our high-purity solutions can enhance your lab's capabilities and project success.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the primary role of a high-precision laboratory oven in the solvothermal synthesis of Cu-BTC? Drive MOF Quality

- What role do high-temperature industrial furnaces play in PGM recovery? Maximize Platinum Yield with Precision Heat

- What are the 3 phases of quenching process? Master the Cooling Stages for Perfect Hardness

- How does multi-stage vacuum distillation facilitate the removal of zinc and cadmium from crude magnesium?

- How does a vacuum diffusion bonding furnace contribute to titanium laminates? Precision for Near-Alpha Alloys

- What temperature is copper brazing in Celsius? Get the Right Heat for Strong Joints

- How does the discharge effect of a DC pulse power supply affect SPS nickel-based alloys? Achieve Rapid Densification

- What is the temperature range for brazing? Master the Critical Heat for Strong Joints