For brazing aluminum, you must use a specialized aluminum-silicon (Al-Si) brazing rod, often designated as 4047 or a similar alloy. These rods have a lower melting point than the base aluminum you are joining. Crucially, successful brazing also requires a specific flux designed to chemically remove the stubborn aluminum oxide layer, which is the primary obstacle to creating a strong bond.

The challenge of joining aluminum isn't the metal itself, but the invisible, high-melting-point layer of aluminum oxide on its surface. Therefore, your success depends less on the specific rod brand and more on using the correct flux and maintaining precise temperature control to manage this oxide layer.

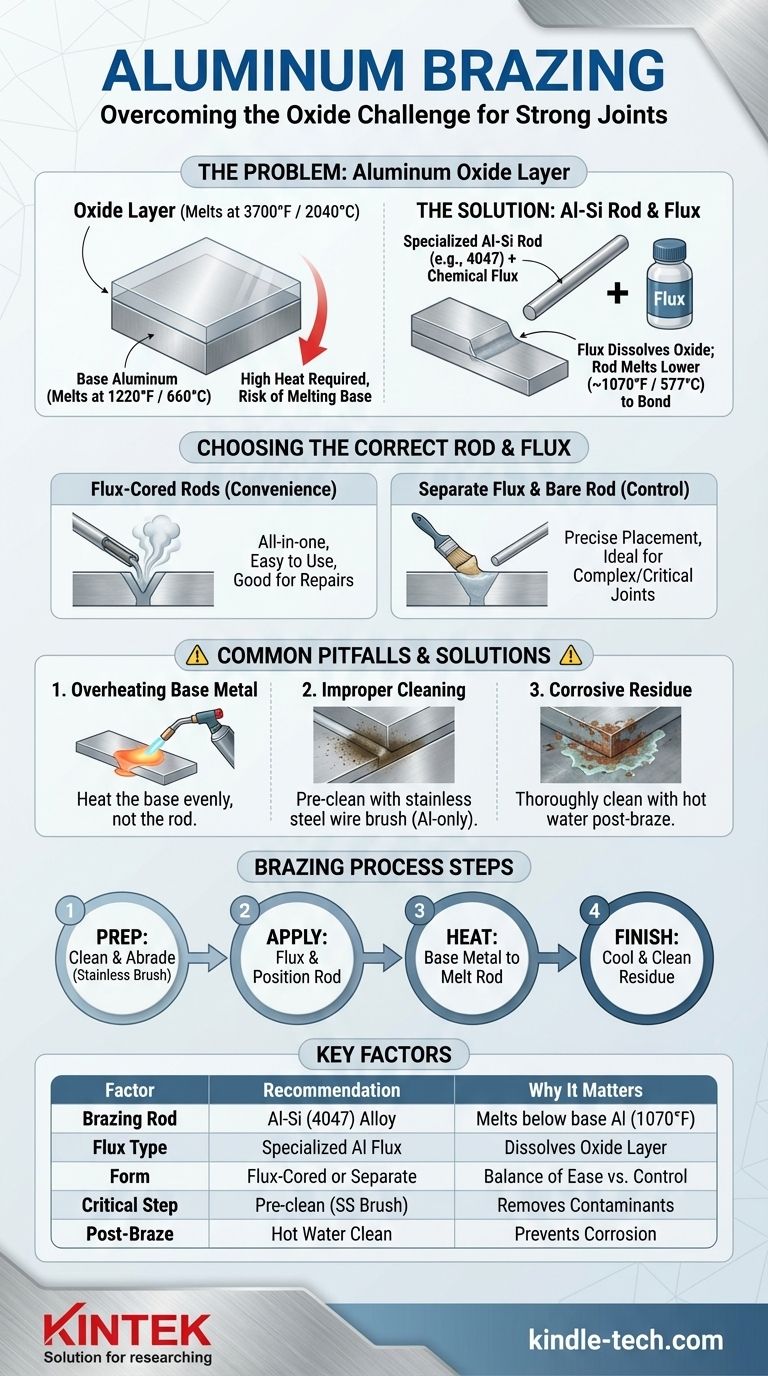

Why Brazing Aluminum is a Unique Challenge

To effectively join aluminum, you must first understand the core problem you are trying to solve. It’s not simply a matter of melting a filler rod into a joint.

The Problem: The Oxide Layer

Every piece of aluminum is protected by a thin, hard, and transparent layer of aluminum oxide.

This oxide layer is the reason aluminum resists corrosion so well, but it is the primary enemy of any joining process. It melts at around 3700°F (2040°C), while the aluminum underneath melts at just 1220°F (660°C).

If you try to heat the joint to melt a standard filler rod, you will melt the base aluminum into a puddle long before you ever break through the oxide layer.

The Solution: Flux and a Low-Temp Filler Rod

The solution is a two-part system: a specialized filler rod and an active chemical flux.

The flux is a chemical agent designed to attack and dissolve the aluminum oxide layer when heated. The aluminum-silicon filler rod is designed to melt at a temperature slightly below that of the base aluminum, allowing it to flow into the joint once the flux has cleared a path.

Choosing the Correct Rod and Flux

While the process is the key, selecting the right materials is the necessary first step. Your choice generally comes down to convenience versus control.

The Standard Choice: Aluminum-Silicon (Al-Si) Rods

The industry standard for aluminum brazing is an alloy of aluminum and silicon, most commonly 4047 (Al-Si12).

The high silicon content gives this alloy two critical properties:

- Lower Melting Point: It becomes liquid at around 1070°F (577°C), well below the melting point of common aluminum alloys.

- Excellent Flow (Wetting): Once molten, it flows easily into tight-fitting joints via capillary action.

Flux-Cored Rods vs. Separate Flux

You can purchase these materials in two primary forms.

Flux-cored rods have the flux powder contained within the rod itself. As you heat the rod, it releases the flux directly into the joint. This is highly convenient and excellent for beginners.

Separate flux involves applying a flux paste or powder to the joint before heating and then introducing a bare brazing rod. This method offers more control over flux placement and is often preferred for complex or critical joints.

Understanding the Trade-offs and Common Pitfalls

Aluminum gives very little warning before it fails. It does not glow red like steel before melting; it simply turns into a liquid puddle. This unforgiving nature leads to common mistakes.

Pitfall #1: Overheating the Base Metal

This is the most common failure. Operators apply too much direct heat to the workpiece, trying to melt the rod.

The correct technique is to heat the base metal evenly around the joint until it is hot enough to melt the rod on contact. The torch should heat the part, not the rod.

Pitfall #2: Improper Cleaning

Flux can only do so much. The surface must be mechanically cleaned before you begin.

Use a stainless steel wire brush (one that is only used for aluminum) to scrub the joint area immediately before applying flux and heat. This removes surface contaminants and a portion of the thick oxide layer, allowing the flux to work more effectively.

Pitfall #3: Forgetting Post-Braze Cleanup

Most aluminum brazing fluxes are corrosive. If left on the joint, they will attract moisture and corrode the aluminum over time.

After the part has cooled, you must clean the joint thoroughly with hot water and a stiff brush to remove all residual flux.

Making the Right Choice for Your Goal

Your project's specific needs will guide your material and process selection.

- If your primary focus is a simple, quick repair: Choose a high-quality flux-cored aluminum-silicon (4047-type) rod. Its all-in-one nature simplifies the process dramatically.

- If your primary focus is joining thin-walled tubes or sheets: Use a separate flux and bare rod for better heat control, and focus on heating the joint broadly and evenly to prevent melting through the thin material.

- If your primary focus is maximum strength or a structural component: Re-evaluate if brazing is the right process. TIG welding, which melts and fuses the base metals, creates a significantly stronger joint than brazing.

Ultimately, success in aluminum brazing is achieved through finesse and an understanding of the material, not through overwhelming heat or force.

Summary Table:

| Key Factor | Recommendation | Why It Matters |

|---|---|---|

| Brazing Rod | Aluminum-Silicon (Al-Si) alloy, e.g., 4047 | Melts at ~1070°F, below base aluminum's melting point |

| Flux Type | Specialized aluminum brazing flux | Dissolves the tough aluminum oxide layer for proper bonding |

| Form | Flux-cored rods (ease) or separate flux + bare rod (control) | Choose based on project complexity and experience level |

| Critical Step | Pre-clean with a stainless steel brush (aluminum-only) | Removes contaminants and aids flux effectiveness |

| Post-Braze | Thoroughly clean with hot water to remove corrosive flux | Prevents long-term corrosion and ensures joint integrity |

Achieve flawless aluminum joints with the right equipment and expertise.

Brazing aluminum requires precision and the correct materials to overcome its challenging oxide layer. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific joining and fabrication needs. Whether you're working on R&D, prototyping, or production, our experts can help you select the ideal brazing rods, fluxes, and heating tools for consistent, strong results.

Let KINTEK empower your laboratory's capabilities. Contact our technical team today to discuss your aluminum brazing requirements and discover how our solutions can enhance your workflow and ensure project success.

Visual Guide

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Boron Nitride (BN) Ceramic Rod for High Temperature Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

People Also Ask

- What is the process of alumina tube manufacturing? From Powder to High-Performance Ceramic

- Is ceramic chemically inert? Unlock the Power of Ultimate Chemical Resistance

- What is the maximum temperature for alumina tube? Unlock Its Full Potential with High Purity

- What is the advantage of ceramic over metal? Unlock Superior Performance in Extreme Conditions

- Why are ceramics more resistant to corrosion? Unlock the Secret to Unmatched Chemical Stability