In a laboratory, the primary tools for crushing and grinding substances range from high-energy mechanical mills to simple manual devices. This equipment is essential for sample preparation, ensuring a homogenous and appropriately sized material for analysis or reaction. The most common automated options include jaw crushers for coarse material, and planetary, vibratory, or ball mills for producing fine powders.

The core decision in choosing grinding equipment is not about finding a single "best" tool, but about matching the grinding mechanism—crushing, impact, or friction—to your starting material's properties and the final particle size required for your specific application.

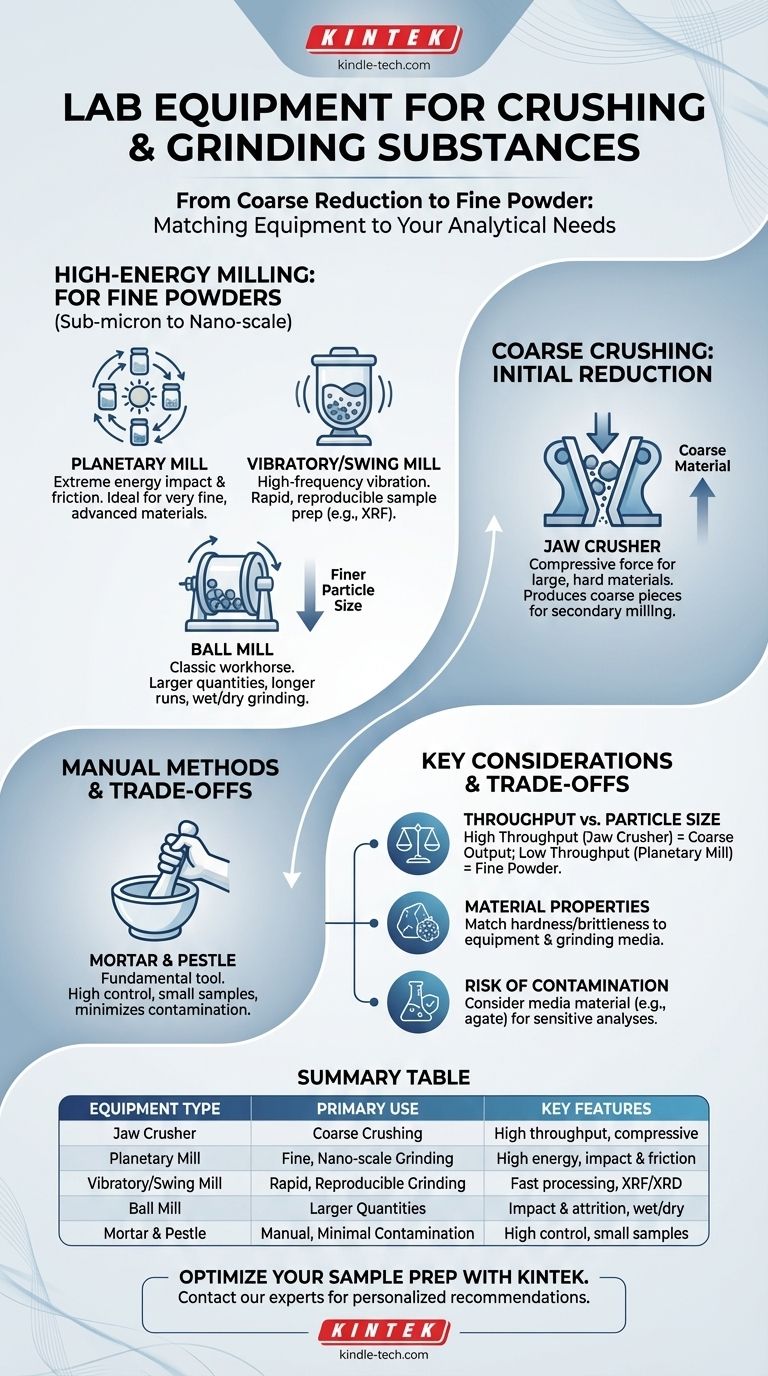

High-Energy Milling for Fine Powders

For most analytical techniques, the goal is to reduce a sample to a fine, uniform powder. High-energy mills accomplish this through intense impact and frictional forces.

Planetary Mills

A planetary mill uses extreme energy for grinding. Grinding jars are arranged on a rotating sun wheel, and they rotate in the opposite direction, creating powerful impact and friction forces between the grinding balls and the sample inside.

This method is ideal for achieving very fine, often sub-micron or nano-scale particle sizes, which is critical for advanced materials research and analysis.

Vibratory and Swing Mills

These mills, often used for sample preparation for X-ray fluorescence (XRF), pulverize material through high-frequency vibration and impact. A grinding vessel (containing the sample and a puck or balls) is shaken aggressively.

They are valued for their speed and reproducibility, processing samples in minutes. As noted, they come in various sizes to handle sample weights from 10g up to 300g.

Ball Mills

A ball mill is a classic workhorse that consists of a rotating drum partially filled with the sample and grinding media (balls). As the drum turns, the media cascades and tumbles, grinding the material through impact and attrition.

While less intense than a planetary mill, a ball mill is excellent for grinding larger quantities of material over longer periods and can also be used for wet grinding.

Coarse Crushing for Initial Reduction

Before a sample can be milled into a fine powder, large pieces often need to be broken down into a manageable size.

Jaw Crushers

A jaw crusher is designed for the first step in sample reduction. It uses compressive force to break down large, hard, and brittle materials like rocks, minerals, or ceramics between a fixed and a moving jaw plate.

Its purpose is not to produce a powder but to generate coarse crushed pieces that are suitable for feeding into a secondary mill.

Manual Grinding Methods

For smaller scales or specific applications, manual methods remain indispensable.

Mortar and Pestle

This is the most fundamental tool for manual grinding. By applying pressure and a circular motion with the pestle inside the mortar bowl, a user can crush and grind small amounts of a substance.

Mortars and pestles are made from various materials (e.g., agate, ceramic, porcelain) to prevent sample contamination, a key consideration when preparing samples for trace element analysis.

Understanding the Trade-offs

Choosing the right equipment requires balancing several key factors.

Throughput vs. Final Particle Size

High-throughput equipment like a jaw crusher can process large volumes quickly but only produces coarse material. In contrast, a planetary mill produces exceptionally fine powder but works with much smaller sample volumes.

Material Properties

The hardness and brittleness of your sample are critical. A jaw crusher excels with hard, brittle rock, but it would be ineffective on a soft, ductile polymer. The grinding media (e.g., steel, tungsten carbide, zirconia) must also be harder than the sample itself.

Risk of Contamination

All mechanical grinding introduces some level of contamination from the grinding surfaces and media. This is a critical consideration for sensitive chemical analyses. Choosing agate or zirconia media can minimize metallic contamination, while a manual mortar and pestle offers the highest level of control.

Selecting the Right Equipment for Your Goal

Your choice should be dictated entirely by your material and your analytical objective.

- If your primary focus is breaking down large, hard materials for initial processing: A jaw crusher is the necessary first step.

- If your primary focus is rapid, reproducible grinding of samples for routine analysis (e.g., XRF, XRD): A vibratory or swing mill is the industry standard.

- If your primary focus is achieving the finest possible particle size for advanced research: A planetary ball mill provides the highest energy input for nano-scale grinding.

- If your primary focus is carefully grinding a small, soft sample with minimal contamination: A manual mortar and pestle offers the most control and purity.

Ultimately, selecting the correct grinding tool is the foundational step for ensuring accurate and reliable analytical results.

Summary Table:

| Equipment Type | Primary Use | Key Features |

|---|---|---|

| Jaw Crusher | Coarse crushing of large, hard materials | High throughput, compressive force |

| Planetary Mill | Fine, nano-scale grinding | High energy, impact & friction |

| Vibratory/Swing Mill | Rapid, reproducible grinding | Fast processing, ideal for XRF/XRD |

| Ball Mill | Grinding larger quantities | Impact & attrition, wet/dry grinding |

| Mortar & Pestle | Manual grinding, minimal contamination | High control, small sample sizes |

Ready to optimize your sample preparation process? KINTEK specializes in providing high-quality lab equipment and consumables tailored to your laboratory's specific needs. Whether you require a robust jaw crusher for initial reduction or a high-precision planetary mill for nano-scale grinding, our experts are here to help you select the perfect tool for accurate and reliable results. Contact us today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Twin Screw Extruder Plastic Granulation Machine

People Also Ask

- What is the role of an industrial dry grinder in the surface modification of 304L stainless steel? Expert Insights

- What is an attritor used for? Achieve Sub-Micron Grinding & Superior Dispersions

- Why is mechanical ball milling necessary for TiAl intermetallic compounds? Optimize Your Sintering Results

- What is the primary function of a ball mill in WCp/Cu FGM preparation? Achieve Uniform Powder Dispersion

- What advantages does a high energy nano mill offer over a traditional ball mill? Optimize Your LiFePO4 Cathode Quality

- What is the primary function of mechanical alloying equipment in high-entropy alloys? Master Solid-State Synthesis

- What is the core function of a high-energy vibratory ball mill? Unlock Advanced Mechanochemical Synthesis

- What is the primary purpose of an ultra-centrifugal mill for Triticale Straw? Boost Your Bio-conversion Efficiency