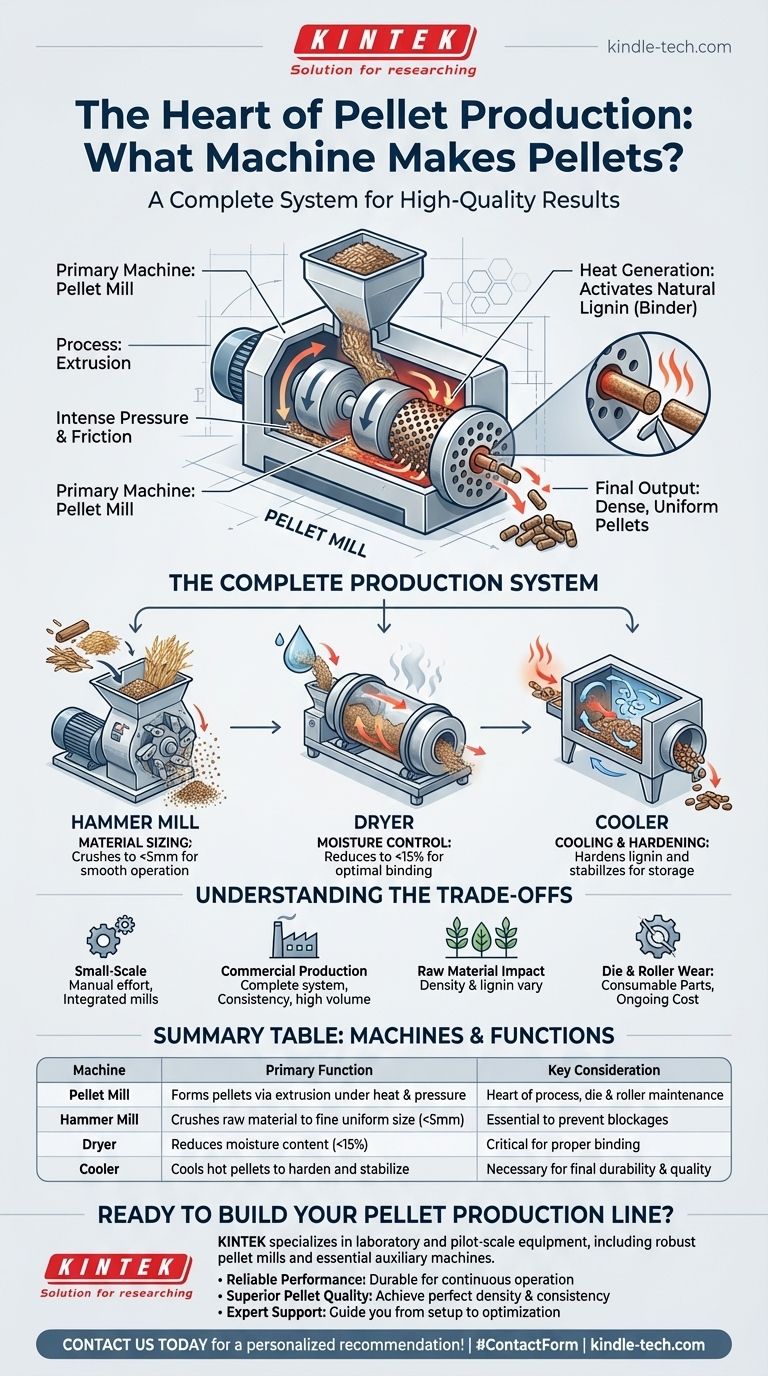

The primary machine used to make pellets is the pellet mill. This device works by forcing raw, prepared biomass or other materials through a perforated metal die under immense pressure, a process known as extrusion. The friction and compression generate heat, which helps bind the material together into a dense, uniform pellet.

A pellet mill is the heart of the process, but successful pellet production depends on a complete system. The final quality of your pellets is determined not just by the mill itself, but by how you prepare the raw material before it ever enters the machine.

How a Pellet Mill Works

A pellet mill is a specialized piece of industrial equipment, but its core function is straightforward. It transforms loose, low-density material into a compact, easily handled fuel or feed.

The Principle of Extrusion

The most common method for creating biomass pellets is extrusion. Inside the mill, rollers continuously press the raw material against a metal plate, or die, which is full of small holes.

The intense pressure forces the material through these holes. This action compresses the material and generates significant friction.

The Role of Heat and Binders

This friction creates heat, which is essential to the process. For wood and other plant-based materials, the heat releases a natural polymer called lignin.

Lignin acts as a natural glue, binding the compressed particles together as they pass through the die. This is what gives the finished pellet its hardness and durability without requiring artificial additives.

Forming the Final Pellet

As the compressed material is forced out of the die holes, a knife or cutter slices the emerging "spaghetti" into pellets of a specified length. The pellets exit the machine hot and still relatively soft.

The System is More Than Just the Mill

While the pellet mill does the core work of forming the pellet, it is only one step in a larger production line. For consistent, high-quality results, several other machines are critical.

Step 1: Material Sizing (Hammer Mill)

The raw material, such as wood chips, sawdust, or straw, must be a uniform and fine consistency before entering the pellet mill.

A hammer mill is used to crush the material into smaller particles. The final particle size must typically be less than 5mm to prevent blockages and ensure proper compression in the die.

Step 2: Moisture Control (Dryer)

Proper moisture content is arguably the most critical factor in pellet production. If the material is too wet, steam can clog the die; if it's too dry, it won't bind together properly.

For most biomass, the ideal moisture content is below 15%. An industrial dryer is often required to reduce the moisture of the raw material to this optimal level.

Step 3: Cooling and Hardening (Cooler)

Pellets exit the mill at a high temperature and are not yet fully durable. They must be cooled quickly to harden the lignin and solidify their shape.

A pellet cooler is used to bring the pellets down to ambient temperature, making them stable for storage and transport.

Understanding the Trade-offs

The complexity of your pelleting operation depends entirely on your goals. What works for a small-scale user is insufficient for a commercial producer.

Small-Scale vs. Commercial Production

For hobbyists or small farm use, all-in-one pellet mills exist. However, the user is still responsible for manually ensuring the material's size and moisture are correct, which can be challenging.

Commercial production lines require the dedicated auxiliary machines—hammer mill, dryer, and cooler—to maintain a consistent and efficient workflow capable of high-volume output.

The Impact of Raw Material

The type of raw material you use directly impacts the process. Hardwoods, softwoods, grasses, and agricultural stalks all have different densities and lignin content.

Each material may require adjustments to die compression ratios, operating temperature, and moisture levels to produce a quality pellet.

Die and Roller Wear

The extreme pressure and friction inherent in pelleting cause significant wear and tear on the mill's core components: the die and the rollers. These are consumable parts and represent a major ongoing operational cost that must be factored into any production plan.

Making the Right Choice for Your Goal

Your approach to pellet production should be guided by your intended scale and desired level of quality control.

- If your primary focus is small-scale or personal use: Look for an integrated pellet mill, but be prepared to carefully manage your raw material's size and moisture manually.

- If your primary focus is consistent, commercial production: You must invest in a complete system including a hammer mill, dryer, and cooler to ensure quality and efficiency.

- If your primary focus is specialized industrial applications: Be aware that other methods like spheronization or layering exist for creating pellets in fields like pharmaceuticals, which have different requirements than biomass.

Understanding the entire pelletizing system, from raw material preparation to final cooling, is the key to producing high-quality pellets reliably.

Summary Table:

| Machine | Primary Function | Key Consideration |

|---|---|---|

| Pellet Mill | Forms pellets via extrusion under heat and pressure. | The heart of the process; requires proper die and roller maintenance. |

| Hammer Mill | Crushes raw material to a fine, uniform size (<5mm). | Essential for preventing die blockages and ensuring smooth operation. |

| Dryer | Reduces moisture content of raw material (ideally to <15%). | Critical for proper binding; too wet or dry causes production issues. |

| Cooler | Cools hot pellets to harden them and stabilize for storage. | Necessary for achieving final pellet durability and quality. |

Ready to Build Your Pellet Production Line?

Producing high-quality pellets consistently requires more than just a mill—it demands a well-integrated system. KINTEK specializes in laboratory and pilot-scale equipment, including robust pellet mills and the essential auxiliary machines needed for success.

We help you achieve:

- Reliable Performance: Durable equipment designed for continuous operation.

- Superior Pellet Quality: Achieve the perfect density, hardness, and consistency for your application.

- Expert Support: Our team understands the nuances of biomass processing and can guide you from setup to optimization.

Whether you're scaling up from R&D or optimizing an existing process, KINTEK has the solutions for your laboratory needs. Contact us today to discuss your project and get a personalized recommendation!

Visual Guide

Related Products

- Twin Screw Extruder Plastic Granulation Machine

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the primary purpose of using a laboratory hydraulic press for pre-pressing? Achieve Optimal Sintering Results

- How does a laboratory hydraulic press assist in XAS sample quality? Precision Pellets for Superior Spectral Clarity

- In what stages of the experimental process for 9-12 wt% Cr steel are laboratory hydraulic presses used?

- How does a screw press work? A Guide to Efficient Liquid-Solid Separation

- Can XRF detect trace elements? A Guide to Limits, Capabilities, and Choosing the Right Tool

- What is the die of a pellet mill? The Core Component Defining Pellet Quality & Efficiency

- Can hydraulic systems that run too hot or too cold cause severe problems over time? Yes, and here's how to prevent it.

- Why is a laboratory hydraulic press utilized for Al-Ti cold press molding? Key Steps to Perfect Sintering