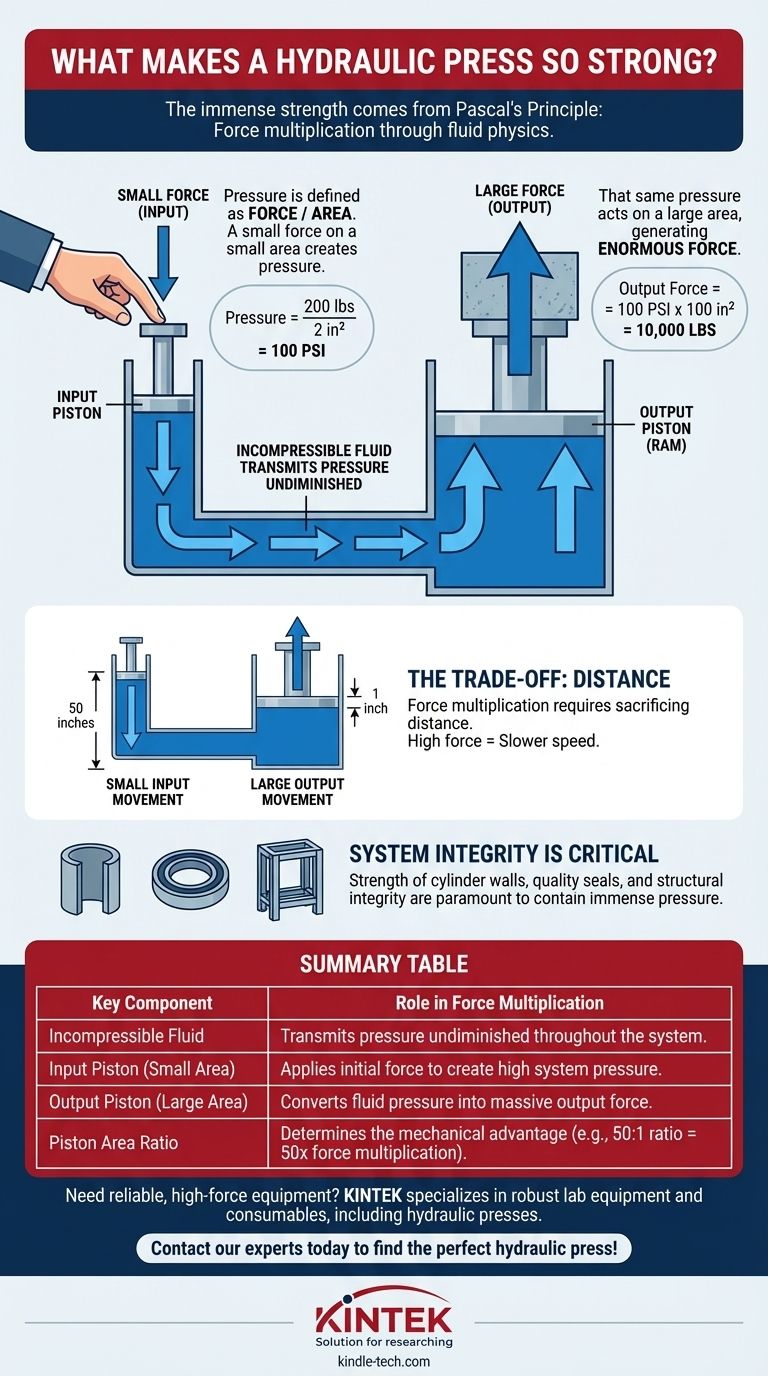

The immense strength of a hydraulic press does not come from complex electronics or motors, but from a simple and elegant principle of fluid physics called Pascal's Principle. This principle allows a small amount of force applied to a small area to be converted into an enormous amount of force acting on a large area, all through the use of an incompressible fluid like oil.

The core concept is force multiplication. By applying pressure to a confined fluid, that same pressure is exerted equally on every part of the container. When this pressure acts on a second piston with a much larger surface area, the resulting output force is magnified proportionally.

The Core Principle: Pascal's Law Explained

To understand the power of a hydraulic press, you must first understand the relationship between force, pressure, and area. The entire system is built on this fundamental interaction.

An Incompressible Fluid

Hydraulic systems use a fluid, typically a specialized oil, that is incompressible. This means it doesn't noticeably shrink or compress when put under pressure.

Because the fluid cannot be squeezed, any force applied to it is transmitted directly to another part of the system instead of being wasted on compressing the fluid itself.

Pressure is Force Over Area

Pressure is defined as a force exerted over a specific area (Pressure = Force / Area). A 10-pound force on 1 square inch creates 10 pounds per square inch (PSI) of pressure.

This simple formula is the key to unlocking force multiplication. By changing the area, you can dramatically change the force, even if the pressure remains the same.

The Magic of Different Piston Sizes

This is where Pascal's Principle creates its effect. The principle states that pressure applied to a confined fluid is transmitted equally and undiminished to all parts of the fluid.

Imagine a sealed system with two pistons: a small one (the input) and a large one (the output).

- A small force is applied to the small input piston. This creates a specific pressure in the fluid (e.g., 100 PSI).

- According to Pascal's law, that 100 PSI of pressure is now present everywhere within the fluid.

- This same 100 PSI now pushes up on the large output piston.

Because the output piston has a much larger area, the resulting force it generates is enormous. If the output piston has 50 times the area of the input piston, the output force will be 50 times greater than the input force.

How This Translates to Mechanical Advantage

The physical components of the press are designed specifically to exploit this principle, giving the machine a massive mechanical advantage.

The Input Piston (The Plunger)

This is the smaller piston where the initial force is applied, either by a hand pump or a small motor. It requires relatively little force to move, but it generates the critical system pressure.

The Output Piston (The Ram)

This is the large piston that does the actual work—crushing, pressing, or lifting. Its massive surface area is what receives the fluid pressure and converts it into a tremendous output force.

A Simple Calculation

- Imagine the small input piston has an area of 2 square inches.

- Imagine the large output ram has an area of 100 square inches (a 50:1 ratio).

- If you apply just 200 pounds of force to the small piston, you create a pressure of 100 PSI (200 lbs / 2 in²).

- That 100 PSI acts on the large ram, producing a massive output force of 10,000 pounds (100 PSI x 100 in²).

Understanding the Trade-offs

This immense force multiplication does not come for free. The system is bound by the laws of physics, which require a fundamental trade-off.

The Cost of Force: Distance

To achieve force multiplication, you must sacrifice distance. For the large piston to move up 1 inch, the small piston must travel a much greater distance.

In our 50:1 ratio example, you would need to move the small piston 50 inches just to raise the large ram 1 inch. This is why hydraulic presses are often powerful but not particularly fast.

System Integrity is Critical

While the principle is simple, the real-world strength of a press depends entirely on the physical components. The system's ability to contain the immense internal pressure is paramount.

The strength of the cylinder walls, the quality of the seals and hoses, and the structural integrity of the frame are what ultimately determine the machine's maximum force rating. A failure in any of these components under pressure can be catastrophic.

Key Takeaways for Understanding Hydraulic Systems

To apply this knowledge, consider how each part of the principle relates to the system's function.

- If your primary focus is mechanical advantage: The force multiplication is determined almost entirely by the ratio between the output and input piston areas. A bigger ratio means more force.

- If your primary focus is system design: The strength of the materials and the quality of the seals are what allow the system to safely contain the immense pressure required to generate force.

- If your primary focus is performance: Always remember the trade-off between force and speed. A system designed for higher force (with a larger piston ratio) will inherently operate more slowly.

Ultimately, the hydraulic press is a testament to how a simple physical law can be engineered to create machines of incredible power.

Summary Table:

| Key Component | Role in Force Multiplication |

|---|---|

| Incompressible Fluid | Transmits pressure undiminished throughout the system. |

| Input Piston (Small Area) | Applies initial force to create high system pressure. |

| Output Piston (Large Area) | Converts fluid pressure into massive output force. |

| Piston Area Ratio | Determines the mechanical advantage (e.g., 50:1 ratio = 50x force multiplication). |

Need reliable, high-force equipment for your lab or production needs?

KINTEK specializes in robust lab equipment and consumables, including hydraulic presses designed for precision and durability. Our solutions are engineered to deliver the consistent, powerful performance your laboratory requires.

Contact our experts today to find the perfect hydraulic press for your application!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- How much psi can a hydraulic press make? From 2,000 PSI to over 50,000 PSI Explained

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What causes hydraulic pressure spikes? Prevent System Damage from Hydraulic Shock

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing