In short, an induction furnace can melt nearly any metal. This includes common ferrous metals like iron and steel, non-ferrous metals like copper and aluminum, and even precious metals such as gold, silver, and platinum. Because of its ability to generate extremely high and controlled temperatures, it is also a preferred method for melting specialized refractory metals.

The versatility of an induction furnace comes from its fundamental operating principle. It does not rely on external flames or heating elements, but instead uses electromagnetic induction to generate heat directly within the metal itself, making it suitable for any material that is electrically conductive.

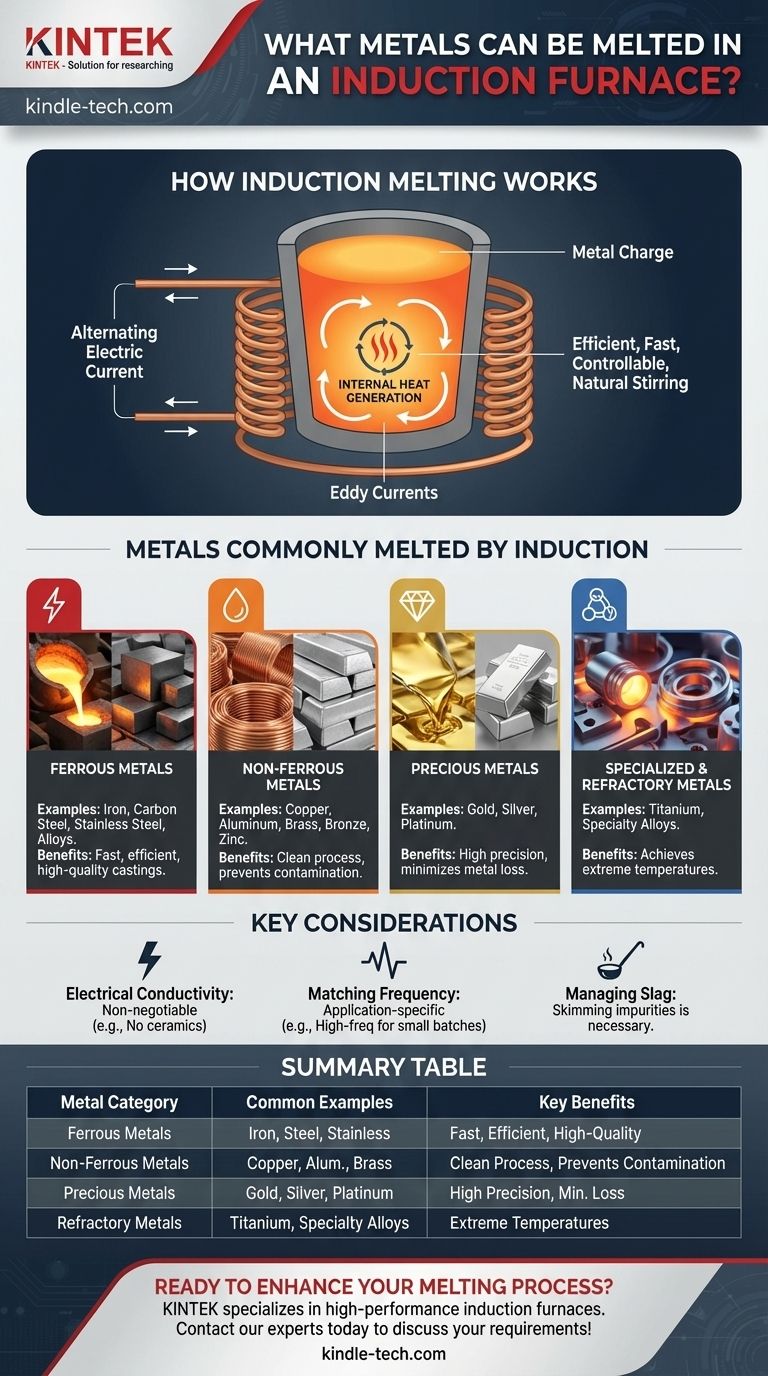

How Induction Melting Works

To understand why induction furnaces are so versatile, you must first understand how they generate heat. The process is fundamentally different from traditional fuel-fired or resistance furnaces.

The Principle of Electromagnetic Induction

An induction furnace uses a powerful alternating electric current that flows through a copper coil. This coil creates a rapidly changing magnetic field around the metal (the "charge") placed inside a crucible.

This magnetic field induces powerful electrical currents, known as eddy currents, to flow within the metal itself.

Internal Heat Generation

The resistance of the metal to the flow of these eddy currents generates intense heat. In effect, the metal becomes its own heating element.

This internal heating is exceptionally efficient, fast, and controllable. It also creates a natural stirring action in the molten metal, which promotes a more uniform temperature and homogenous mixture when creating alloys.

Metals Commonly Melted by Induction

The principle of induction works on a vast spectrum of electrically conductive materials. We can group them into a few key categories.

Ferrous Metals

This is one of the most common applications for induction furnaces. They are used extensively for melting and holding iron, carbon steel, stainless steel, and various steel alloys. The technology is valued in foundries for its speed and for producing high-quality castings.

Non-Ferrous Metals

Induction is highly effective for melting non-ferrous metals. This includes copper, aluminum, zinc, brass, and bronze. The clean melting environment prevents contamination from combustion by-products, which is critical for maintaining the purity of these metals.

Precious Metals

The precision and lack of contamination make induction a superior choice for melting gold, silver, and platinum-group metals. The process minimizes metal loss, which is a significant economic factor when dealing with such high-value materials.

Specialized and Refractory Metals

Induction furnaces can achieve the extreme temperatures necessary to melt refractory metals, which have very high melting points. This makes them suitable for applications involving materials like titanium and other specialty alloys used in the aerospace and medical industries.

Understanding the Trade-offs and Considerations

While highly versatile, the effectiveness of an induction furnace depends on a few key factors. Understanding these will ensure you apply the technology correctly.

Electrical Conductivity is Non-Negotiable

The process is entirely dependent on the material's ability to conduct electricity. Non-conductive materials like ceramics or dry sand cannot be melted directly by induction, though they are often used for the crucible that holds the metal.

Matching Frequency to the Application

Induction furnaces operate at different frequencies (e.g., line frequency, medium frequency, high frequency). The optimal frequency depends on the type of metal, the quantity being melted, and the desired stirring effect. For example, high-frequency furnaces are often better for melting smaller quantities or highly specialized metals.

Managing Slag and Impurities

While induction is a clean process, melting scrap metal or impure materials will still produce slag (non-metallic impurities) that floats on top of the melt. A proper furnace operation includes skimming this slag to ensure the final product's purity.

Making the Right Choice for Your Goal

The decision to use an induction furnace should be based on your specific material and production goals.

- If your primary focus is large-scale iron and steel production: Induction is a modern, energy-efficient, and highly controllable standard for foundries.

- If your primary focus is high-purity non-ferrous metals: The clean, contained melting process of an induction furnace is ideal for copper and aluminum.

- If your primary focus is precious metals or jewelry: The precision, speed, and low material loss of induction furnaces are unmatched for gold, silver, and platinum.

- If your primary focus is creating specialized alloys or recycling scrap: Induction provides the excellent temperature control and natural stirring needed for creating homogenous mixtures.

Ultimately, if your material conducts electricity, an induction furnace is almost certainly a viable and often superior melting technology.

Summary Table:

| Metal Category | Common Examples | Key Benefits of Induction Melting |

|---|---|---|

| Ferrous Metals | Iron, Carbon Steel, Stainless Steel | Fast, efficient, high-quality castings |

| Non-Ferrous Metals | Copper, Aluminum, Brass, Bronze | Clean process, prevents contamination |

| Precious Metals | Gold, Silver, Platinum | High precision, minimizes metal loss |

| Refractory Metals | Titanium, Specialty Alloys | Achieves extreme temperatures for advanced alloys |

Ready to enhance your melting process with precision and efficiency?

KINTEK specializes in high-performance lab equipment, including induction furnaces perfect for melting ferrous, non-ferrous, precious, and refractory metals. Our solutions deliver the clean, controlled, and efficient heating your laboratory or production facility needs.

Contact our experts today to discuss your specific metal melting requirements and discover the ideal induction furnace for your application!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- Why use VIM for rare earth steel? Essential Precision for Melting Reactive Lanthanum and Cerium

- What scrap is used in an induction furnace? Choosing the Right Metal for Efficient Melting

- What is the temperature range of induction heating? From Gentle Warming to Extreme Melting

- What is the main application of indirect arc furnace is to melt? Master Non-Ferrous Alloy Melting with Precision

- What are the technical advantages of using a vacuum induction melting furnace? Enhance Zirconium-Chromium Alloy Purity

- Why does an induction furnace blast? Prevent Catastrophic Steam Explosions in Your Foundry

- What are the reactions in an induction furnace? Mastering Metallurgical Control for Your Melt

- What is the function of a high-frequency induction furnace in NiSi production? Achieving Chemical Homogeneity