For permanent histological slides, the most widely used method for mounting specimens is coverslipping with a resinous mounting medium. This technique involves placing a clear, adhesive-like substance over the stained tissue section on a glass slide and then covering it with a thin glass coverslip to create a permanent, high-resolution preparation for microscopic viewing.

Mounting is not just a final protective step; it is a critical optical and archival procedure. The primary goal is to match the refractive index of the specimen to the glass slide, minimizing light scatter to produce a clear image while simultaneously preserving the tissue for decades.

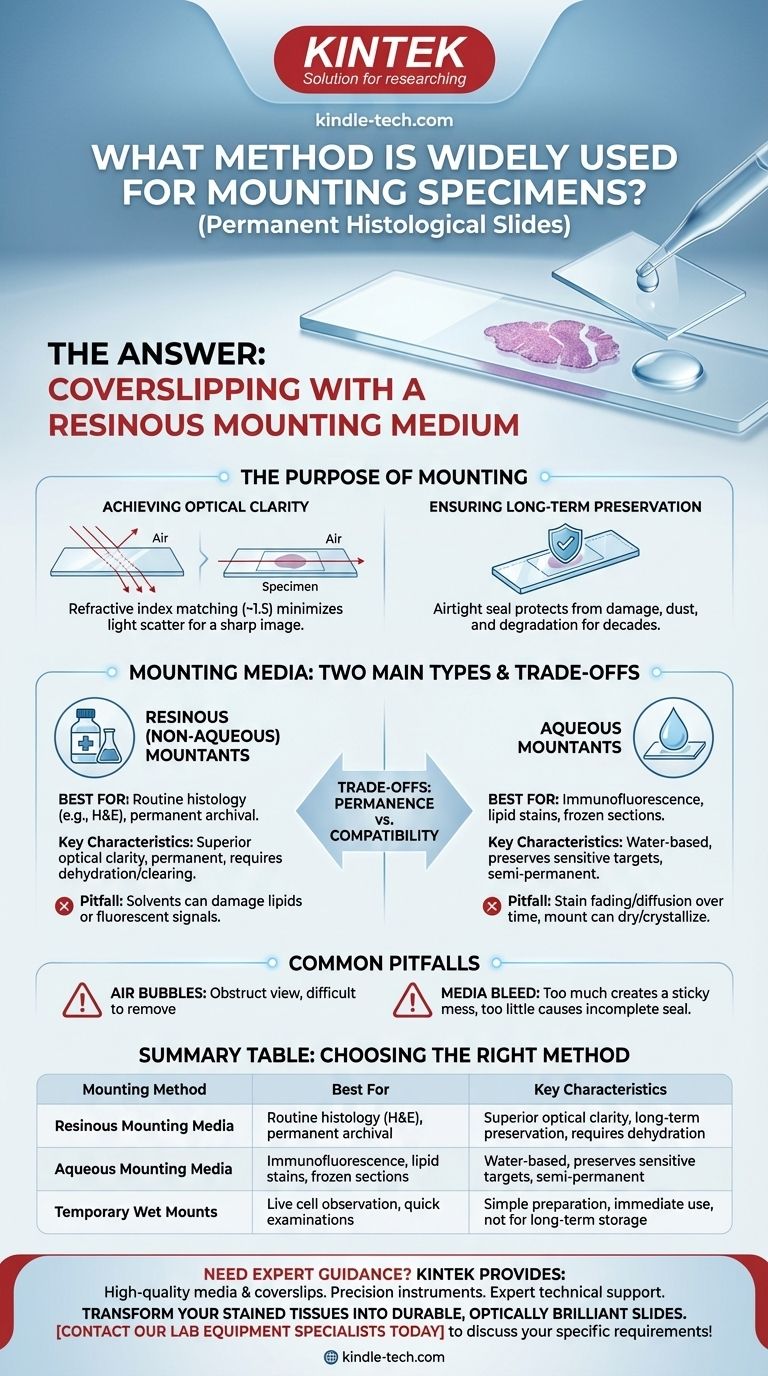

The Purpose of Mounting: Beyond Simple Protection

While a coverslip physically protects the tissue, the true purpose of mounting is rooted in the physics of light and the need for long-term preservation.

Achieving Optical Clarity

The single most important function of a mounting medium is to provide optical clarity. When light passes from one substance to another (like from the glass slide, through the tissue, and into the air), it bends or refracts.

A mounting medium is chosen because its refractive index (typically ~1.5) is very close to that of both the glass slide and the fixed tissue. This uniformity minimizes light refraction, reducing scatter and allowing for a sharp, clear, high-resolution image under the microscope.

Ensuring Long-Term Preservation

A properly mounted slide creates an airtight seal. This protects the delicate, stained tissue section from physical damage, dust, oxidation, and microbial growth.

Permanent resinous media harden over time, permanently affixing the coverslip and creating an archival-quality specimen that can be stored and studied for years or even decades without significant degradation.

The Core of the Technique: Mounting Media

The choice of mounting medium is the most critical decision in the mounting process. These media fall into two main categories, each with specific uses.

Resinous (Non-Aqueous) Mountants

These are the most common type for routine histology. They are synthetic resins, like acrylics or polystyrenes, dissolved in an organic solvent such as xylene or toluene.

Because these media are not miscible with water, the tissue section must first be completely dehydrated through a series of alcohol baths and then "cleared" with an agent like xylene before mounting. This process makes them the standard for stains like Hematoxylin and Eosin (H&E).

Aqueous Mountants

These are water-based media, essentially gels or syrups, used when the tissue or stain cannot withstand the dehydration process required for resinous media.

This is critical for techniques like frozen section analysis, certain immunofluorescence protocols, and staining methods where the stain is soluble in alcohol (e.g., fat stains like Oil Red O).

Understanding the Trade-offs

The decision between mounting methods is a balance between the need for permanence and the chemical compatibility of the staining procedure.

Permanence vs. Compatibility

Resinous mounts offer superior optical quality and are considered permanent. However, the solvents used (alcohols, xylene) can destroy or extract certain cellular components, such as lipids, or quench fluorescent signals.

Aqueous mounts solve this compatibility issue but are generally considered non-permanent or semi-permanent. Over time, the stain may fade or diffuse through the medium, and the mount itself can dry out and crystallize, degrading the image.

Common Pitfalls: Air Bubbles and Media Bleed

The most common technical error is trapping air bubbles under the coverslip. These bubbles obstruct the view of the tissue and are difficult to remove once the medium begins to set.

Another issue is using too much or too little medium. Too much causes the medium to "bleed" out from under the coverslip, creating a sticky mess. Too little results in an incomplete seal and areas without proper optical clearance.

Selecting the Right Method for Your Specimen

Your choice of mounting method should be dictated entirely by your staining technique and your archival goals.

- If your primary focus is routine histology (e.g., H&E, Trichrome) for long-term archival: Use a resinous, non-aqueous mounting medium after thorough dehydration and clearing.

- If your primary focus is analyzing lipids or performing immunofluorescence: Use an aqueous mounting medium immediately after staining to prevent damage to the target molecules.

- If your primary focus is observing living, unstained cells (e.g., bacteria in water): Use a simple temporary wet mount with water or saline, as no permanent preservation is needed.

Ultimately, selecting the correct mounting protocol is essential for transforming a stained piece of tissue into a durable and optically brilliant diagnostic tool.

Summary Table:

| Mounting Method | Best For | Key Characteristics |

|---|---|---|

| Resinous Mounting Media | Routine histology (H&E), permanent archival | Superior optical clarity, long-term preservation, requires dehydration |

| Aqueous Mounting Media | Immunofluorescence, lipid stains, frozen sections | Water-based, preserves sensitive targets, semi-permanent |

| Temporary Wet Mounts | Live cell observation, quick examinations | Simple preparation, immediate use, not for long-term storage |

Need expert guidance for your histological mounting needs?

At KINTEK, we understand that proper specimen mounting is crucial for achieving clear, diagnostic-quality results. Whether you're working with routine H&E stains or sensitive immunofluorescence protocols, having the right equipment and consumables makes all the difference.

We provide:

- High-quality mounting media and coverslips for every application

- Precision instruments for consistent, bubble-free results

- Expert technical support to help you select the optimal mounting protocol

Let us help you transform your stained tissues into durable, optically brilliant slides. Contact our lab equipment specialists today to discuss your specific requirements!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Lab Infrared Press Mold

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the difference between hot mounting and cold mounting? Choose the Right Method for Your Sample

- What is the function and maintenance of a polishing glass base? Ensure Perfect Sample Preparation Every Time

- What are the characteristics and maintenance instructions for metallographic polishing suede? Ensure a Perfect Finish

- How do alumina and cerium oxide polishing powders aid high-entropy alloy prep? Achieve Mirror-Like Precision

- What is the temperature of hot mounting? A Guide to Perfect Specimen Encapsulation

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- What is a hot mounting press machine? Precision Control for Metallurgy & Electronics Assembly

- What is the primary purpose of using high-precision grinding and polishing for metal alloy specimens? | KINTEK