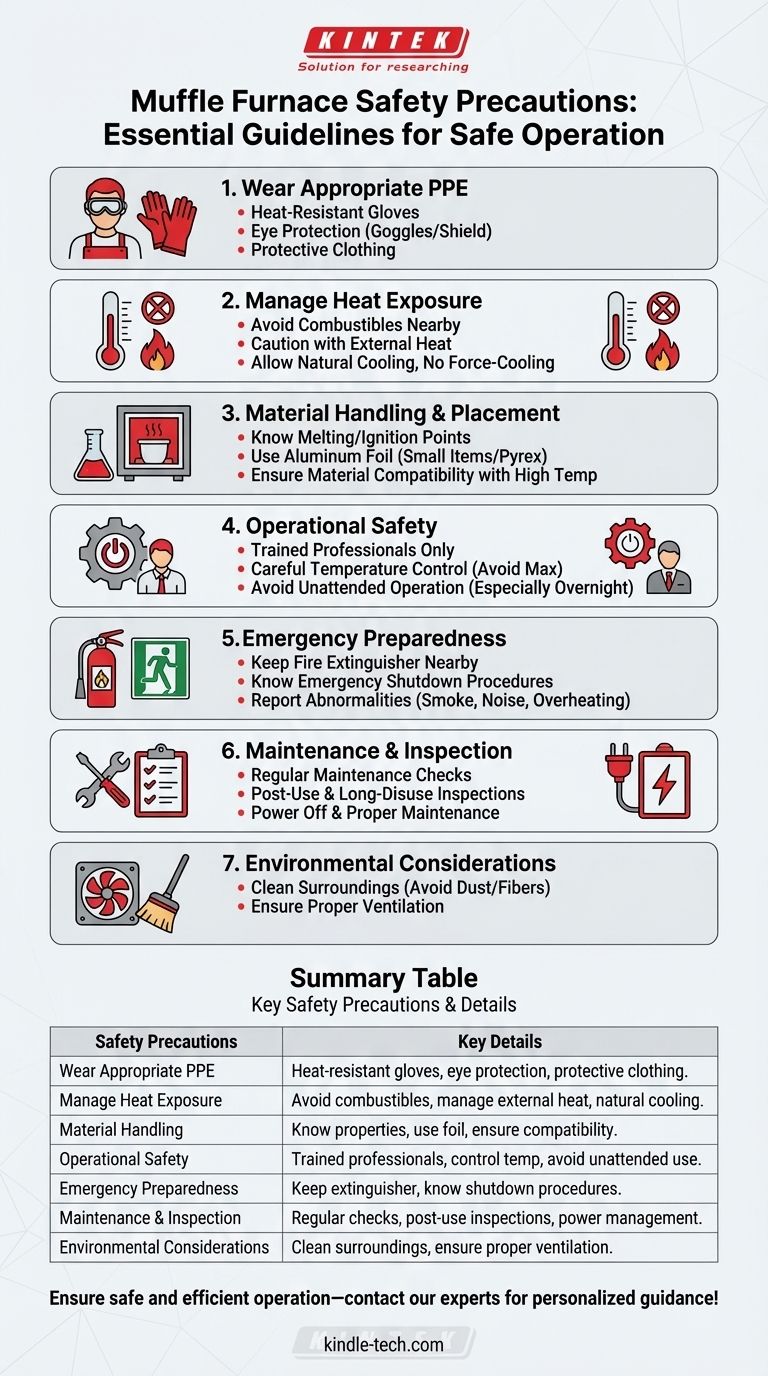

Using a muffle furnace requires strict adherence to safety precautions to prevent accidents, injuries, and equipment damage. Key precautions include wearing appropriate personal protective equipment (PPE), managing heat exposure, ensuring proper placement of materials, and maintaining the furnace regularly. Additionally, users must be aware of emergency procedures, avoid unattended operation, and ensure the furnace is used in a clean and safe environment. Proper handling of materials, temperature control, and post-use procedures are also critical to safe operation.

Key Points Explained:

-

Wear Appropriate Personal Protective Equipment (PPE):

- Heat-Resistant Gloves: Use gloves that can withstand the operating temperature of the furnace to prevent burns when handling hot materials or adjusting the furnace.

- Eye Protection: Wear safety goggles or a face shield to protect against sparks, splashes, or flying debris.

- Protective Clothing: Use heat-resistant clothing to minimize exposure to high temperatures and prevent burns.

-

Manage Heat Exposure:

- Avoid Combustibles: Keep the furnace away from flammable materials to prevent fire hazards.

- External Heat Management: Be cautious of the heat radiating from the furnace exterior to avoid burns or accidental contact.

- Cooling Procedures: After use, allow the furnace to cool naturally before opening the door. Do not force-cool the furnace, as rapid temperature changes can damage the equipment.

-

Material Handling and Placement:

- Know Material Properties: Understand the melting or ignition points of all materials placed in the furnace to avoid accidents.

- Use Aluminum Foil: Wrap smaller items or cover open ends of Pyrex glass with aluminum foil to prevent contamination or damage.

- Ensure Compatibility: Verify that all materials inside the furnace can withstand the high temperatures to prevent melting, combustion, or other hazards.

-

Operational Safety:

- Professional Use: Only trained professionals should operate the muffle furnace to ensure proper handling and minimize risks.

- Temperature Control: Adjust the temperature carefully and avoid exceeding the furnace's maximum operating temperature (e.g., 1200°C).

- Avoid Unattended Operation: Do not leave the furnace running unattended, especially overnight, to prevent accidents caused by equipment failure or overheating.

-

Emergency Preparedness:

- Fire Extinguisher: Keep a fire extinguisher nearby in case of fire emergencies.

- Emergency Procedures: Be familiar with emergency shutdown procedures and contact information for maintenance personnel in case of abnormalities like smoke, unusual noise, or overheating.

-

Maintenance and Inspection:

- Regular Maintenance: Perform frequent checks to ensure the furnace is in good working condition and prevent accidents caused by automatic control failure.

- Post-Use Checks: After long periods of disuse, inspect the furnace for dryness and perform dry treatment if necessary.

- Power Management: Always turn off the power supply after use and ensure the furnace is properly maintained for future operations.

-

Environmental Considerations:

- Clean Surroundings: Keep the area around the furnace clean to prevent dust or fibers from entering, which could cause contamination or fire hazards.

- Ventilation: Ensure proper ventilation to avoid the buildup of harmful fumes or gases.

By following these precautions, users can safely operate a muffle furnace, minimize risks, and extend the lifespan of the equipment.

Summary Table:

| Safety Precautions | Key Details |

|---|---|

| Wear Appropriate PPE | Heat-resistant gloves, eye protection, and protective clothing to prevent burns. |

| Manage Heat Exposure | Avoid combustibles, manage external heat, and allow natural cooling. |

| Material Handling | Know material properties, use aluminum foil, and ensure compatibility. |

| Operational Safety | Operate by trained professionals, control temperature, and avoid unattended use. |

| Emergency Preparedness | Keep a fire extinguisher nearby and know emergency shutdown procedures. |

| Maintenance & Inspection | Regular checks, post-use inspections, and proper power management. |

| Environmental Considerations | Maintain clean surroundings and ensure proper ventilation. |

Ensure safe and efficient muffle furnace operation—contact our experts today for personalized guidance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the precaution for muffle furnace? Essential Safety Protocols for Lab Excellence

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- What is the use of muffle furnace in food industry? Essential for Accurate Food Ash Analysis

- What is the heating mechanism of a muffle furnace? Achieve Clean, Uniform High-Temperature Processing

- What is the application of muffle furnace in food industry? Essential for Accurate Food Ash Analysis