To get the most from a PVD process, you must avoid using it for applications where coating non-line-of-sight surfaces is critical. You should not treat it as a low-cost, high-speed manufacturing solution, nor should you underestimate the operational requirements for part handling and equipment maintenance. Ignoring these constraints often leads to poor results and budget overruns.

The core limitations of Physical Vapor Deposition (PVD) stem from its nature as a line-of-sight process conducted in a vacuum. This single principle dictates which part geometries are suitable, drives up operational complexity, and ultimately defines its cost structure.

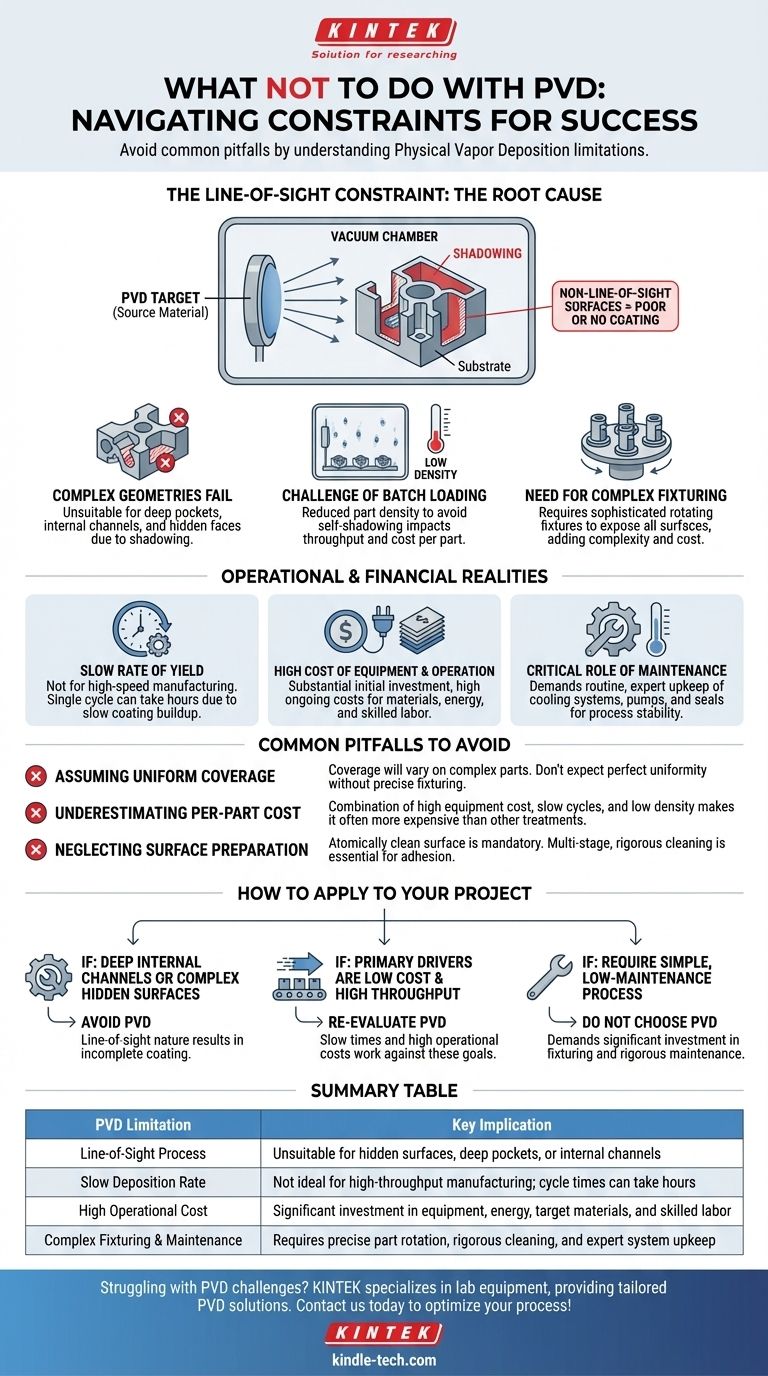

The Line-of-Sight Constraint: The Root of Most Limitations

PVD works by bombarding a source material (the "target") with ions in a vacuum, causing atoms to vaporize and travel in a straight line to coat your part (the "substrate"). Understanding this "line-of-sight" travel is key to avoiding common failures.

Why Complex Geometries Fail

Because the coating material travels in a straight path, any surface not directly visible to the source will not get coated. This phenomenon is known as shadowing.

This makes PVD unsuitable for coating the insides of long tubes, deep pockets, or the hidden faces of intricate parts. The coating will be thick on the exposed surfaces and thin or nonexistent on the "shadowed" ones.

The Challenge of Batch Loading

To avoid parts shadowing each other, they must be loaded into the PVD chamber at a reduced density. They need to be spaced out carefully so that the coating vapor can reach all intended surfaces.

This directly impacts throughput. You can't simply pack the chamber full. This low packing density contributes significantly to the overall cost per part.

The Need for Complex Fixturing

To compensate for shadowing on a single part, components are often mounted on complex rotating fixtures or carousels. These systems turn the parts during the coating process to expose different faces to the vapor source.

While effective, this adds another layer of complexity and cost. The design and operation of these fixtures require significant technical expertise.

Understanding the Operational and Financial Realities

Beyond its physical constraints, PVD presents specific operational and financial challenges that you should not overlook during project planning.

PVD is Not a High-Speed Process

The references note a slow rate of yield, which means the coating builds up very slowly. Depending on the material and desired thickness, a single PVD cycle can take several hours.

This is not a quick "dip and dry" process. The slow deposition rate is a fundamental aspect that limits its use in high-velocity manufacturing unless multiple expensive systems are run in parallel.

The High Cost of Equipment and Operation

PVD is an inherently expensive technology. The initial capital investment for the vacuum chamber, power supplies, and control systems is substantial.

Ongoing costs are also high. These include the consumption of high-purity target materials, significant energy usage, and the need for skilled technicians to operate and maintain the equipment.

The Critical Role of Maintenance

PVD systems are sophisticated machines that demand routine, expert maintenance. A reliable cooling system is essential to manage the immense heat generated.

Furthermore, the vacuum pumps, chamber seals, and power sources all require consistent upkeep to ensure process stability and repeatable results. You should not assume PVD is a "set it and forget it" technology.

Common Pitfalls to Avoid

Based on these limitations, several common misconceptions lead to failed PVD projects. Being aware of them is the first step to success.

Assuming Uniform Coverage

The most frequent mistake is assuming PVD will provide a perfectly uniform coating over an entire complex part. Unless your part is relatively simple and fixtured correctly, coverage will vary.

Underestimating the Per-Part Cost

Do not mistake PVD for a cheap plating alternative. The combination of high equipment cost, slow cycle times, low batch density, and skilled labor means the cost-per-part is often higher than other surface treatments.

Neglecting Surface Preparation

PVD coatings require an atomically clean surface to adhere properly. You cannot place a part directly from a machine shop into a PVD chamber. A multi-stage, rigorous cleaning process is mandatory, and you should not cut corners here.

How to Apply This to Your Project

Use these constraints as a guide to determine if PVD is the right path for your specific goal.

- If your part has deep internal channels or complex, hidden surfaces: Avoid PVD, as its line-of-sight nature will result in incomplete and non-functional coating.

- If your primary drivers are low cost and high throughput: Re-evaluate PVD, as the slow cycle times, low batch density, and high operational costs work directly against these goals.

- If you require a simple, low-maintenance process: Do not choose PVD, as it demands significant investment in complex fixturing, process control, and rigorous equipment maintenance.

By respecting these fundamental constraints, you can accurately assess whether PVD is the correct strategic investment for your application.

Summary Table:

| PVD Limitation | Key Implication |

|---|---|

| Line-of-Sight Process | Unsuitable for coating hidden surfaces, deep pockets, or internal channels |

| Slow Deposition Rate | Not ideal for high-throughput manufacturing; cycle times can take hours |

| High Operational Cost | Significant investment in equipment, energy, target materials, and skilled labor |

| Complex Fixturing & Maintenance | Requires precise part rotation, rigorous cleaning, and expert system upkeep |

Struggling with coating complex geometries or managing high per-part costs? KINTEK specializes in lab equipment and consumables, providing tailored PVD solutions that address your specific laboratory challenges. Our experts help you navigate technical constraints, optimize fixturing, and ensure reliable performance. Contact us today to enhance your coating process efficiency and achieve consistent, high-quality results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition