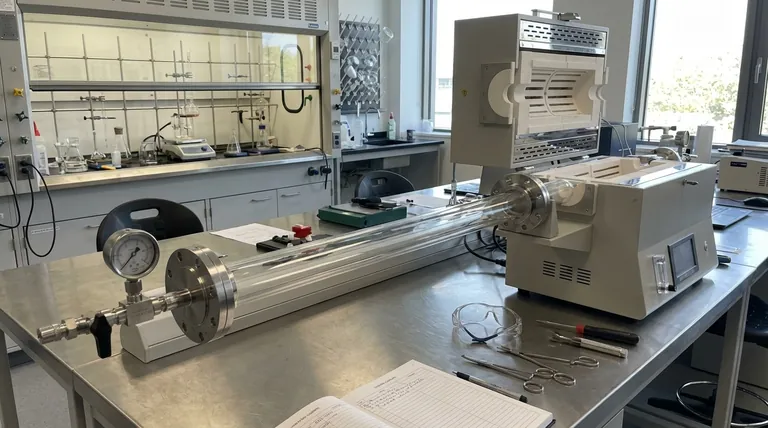

The size of a quartz tube is not a single standard dimension. Instead, tubes are manufactured to fit specific application requirements, defined by their inner diameter, outer diameter, and length. For example, a common process tube for a laboratory furnace might have an outer diameter of 100mm, an inner diameter of 92mm, and a length of 355mm, often integrated with stainless steel flanges for vacuum and gas control.

The core takeaway is that a "quartz tube" is rarely just a simple tube. It is a component within a larger system, and its dimensions are dictated entirely by the requirements of that system—be it a furnace, a chemical reactor, or an industrial process.

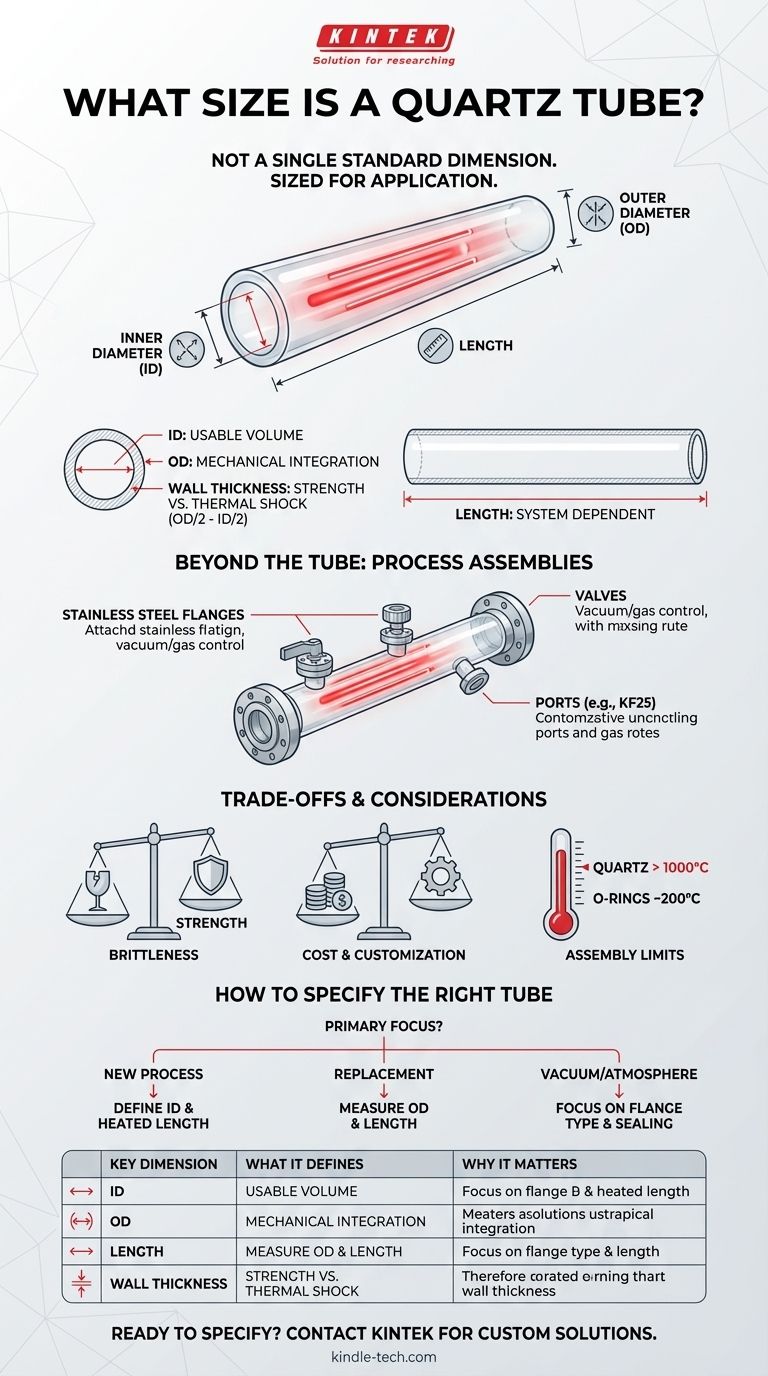

Deconstructing Quartz Tube Specifications

To specify a quartz tube correctly, you must understand its fundamental dimensions. These measurements determine its capacity, its compatibility with other equipment, and its structural integrity.

Inner Diameter (ID)

The inner diameter is arguably the most critical dimension from a process standpoint. It defines the usable volume or working area inside the tube.

This is the space where your sample will be heated, a chemical reaction will occur, or a process will be carried out. It directly constrains the size of your work.

Outer Diameter (OD)

The outer diameter is the primary dimension for mechanical integration. The tube must fit correctly within the bore of a furnace, a support collar, or other mounting hardware.

An incorrect OD means the tube will either not fit or will be too loose, leading to poor thermal transfer and potential safety hazards.

Wall Thickness

Wall thickness is the difference between the outer and inner radii (OD/2 - ID/2). In our example (100mm OD, 92mm ID), the wall thickness is 4mm.

Thicker walls provide greater mechanical strength and rigidity, but they can also reduce the tube's resistance to thermal shock. Thinner walls heat and cool faster but are more fragile.

Length

The length of the tube is determined by the specific equipment it's used in. For a tube furnace, the length must be sufficient to span the entire heated zone and extend into the cooler end zones to accommodate sealing flanges.

Beyond the Tube: Understanding Process Assemblies

Often, a quartz tube is part of a complete process assembly. The reference to flanges, valves, and ports points to this more complex reality. Understanding these components is essential.

The Role of Flanges

Flanges are fitted to the ends of the quartz tube to create a seal. This is critical for applications requiring a vacuum or a controlled gas atmosphere.

These are typically made of stainless steel and use a compressible O-ring to seal against the polished end of the quartz tube, enabling high-vacuum connections.

Valves and Interfaces

Flanges are equipped with ports for various functions. Needle valves allow for the precise introduction or venting of gases.

A standardized vacuum interface, like a KF25 port, allows for the quick and reliable connection of a vacuum pump. Other ports may be included for inserting sensors, such as a thermocouple to measure the temperature inside the tube accurately.

Understanding the Trade-offs

While quartz is an exceptional material, it is not without limitations. A clear-eyed view of its trade-offs is necessary for successful implementation.

Brittleness vs. Strength

Fused quartz has excellent thermal strength but is a brittle material, like all glasses. It can withstand immense heat and pressure changes but will fracture easily from sharp mechanical impact or being dropped.

Cost and Customization

High-purity fused quartz is a specialty material and is significantly more expensive than borosilicate glass or ceramic tubes like alumina. Complex customizations, such as unique flange designs or port placements, will further increase the cost.

Assembly vs. Material Limits

The performance of the entire assembly is often limited by its weakest component. While a quartz tube can handle over 1000°C, the Viton O-rings commonly used in sealing flanges typically have a maximum service temperature of around 200°C. This means the ends of the tube assembly must remain cool.

How to Specify the Right Quartz Tube

Choosing the correct dimensions is about matching the tube to your specific technical goal. Your primary objective will determine which specifications are most critical.

- If your primary focus is defining a new process: Start by defining the required inner diameter for your sample and the heated length you need, then source a furnace and tube assembly that meets those needs.

- If your primary focus is replacing an existing tube: You must precisely measure the outer diameter and overall length of the current tube to ensure the replacement will fit your existing furnace and fixtures.

- If your primary focus is vacuum or atmosphere control: Pay closest attention to the flange type and sealing mechanism, as these components will dictate the ultimate vacuum level and atmospheric integrity of your system.

Understanding these individual components and how they interact empowers you to specify a quartz tube assembly with precision and confidence.

Summary Table:

| Key Dimension | What It Defines | Why It Matters |

|---|---|---|

| Inner Diameter (ID) | Usable working volume | Dictates sample size and process capacity |

| Outer Diameter (OD) | Mechanical fit | Ensures compatibility with furnace bore and supports |

| Length | System integration | Must span the heated zone and accommodate end flanges |

| Wall Thickness | Strength & thermal shock | Balances mechanical rigidity with heating/cooling rates |

Ready to specify the perfect quartz tube for your application?

At KINTEK, we specialize in manufacturing high-purity quartz tubes and complete process assemblies tailored to your laboratory's unique requirements. Whether you need a standard replacement tube or a custom assembly with integrated flanges, valves, and ports for vacuum or atmosphere control, our experts will ensure a perfect fit and optimal performance for your furnace or reactor.

Contact KINTEK today to discuss your project and get a precise quote. Let us provide you with the durable, high-performance lab equipment your research depends on.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What physical role do specialized tooling fixtures play in the reactor layout for airtight SiC coating? Precision Guide

- What are the advantages of using zirconia milling jars for sulfide electrolytes? Enhance Purity and Conductivity

- What environmental conditions must a ball mill jar meet? Prevent Fe3Al Oxidation with Advanced Sealing

- Why is a programmable temperature controller necessary during the annealing process of manganese coatings?

- Why are PID temperature controllers and internal cooling systems essential for autohydrolysis? Precision & Quenching

- What is the function of alumina ceramic balls in MAX phase testing? Enhance Your High-Temp Material Characterization

- What causes the severe thermal-shock load on a pusher plate in a sintering furnace? The Trade-Off for High-Efficiency Manufacturing

- Why is magnetic stirring equipment essential in GPTMS/BPA hybrid synthesis? Achieve Structural Homogeneity