The annealing temperature for steel is not a single value but a specific range determined by the steel's carbon content and the desired outcome. For a full anneal designed to achieve maximum softness, steel is typically heated to a temperature between 815-915°C (1500-1675°F), held at that temperature, and then cooled extremely slowly.

The central challenge is not finding a single temperature, but understanding that "annealing" is a family of processes. The correct temperature and procedure depend entirely on why you are annealing the steel—whether for maximum softening, stress relief, or improved machinability.

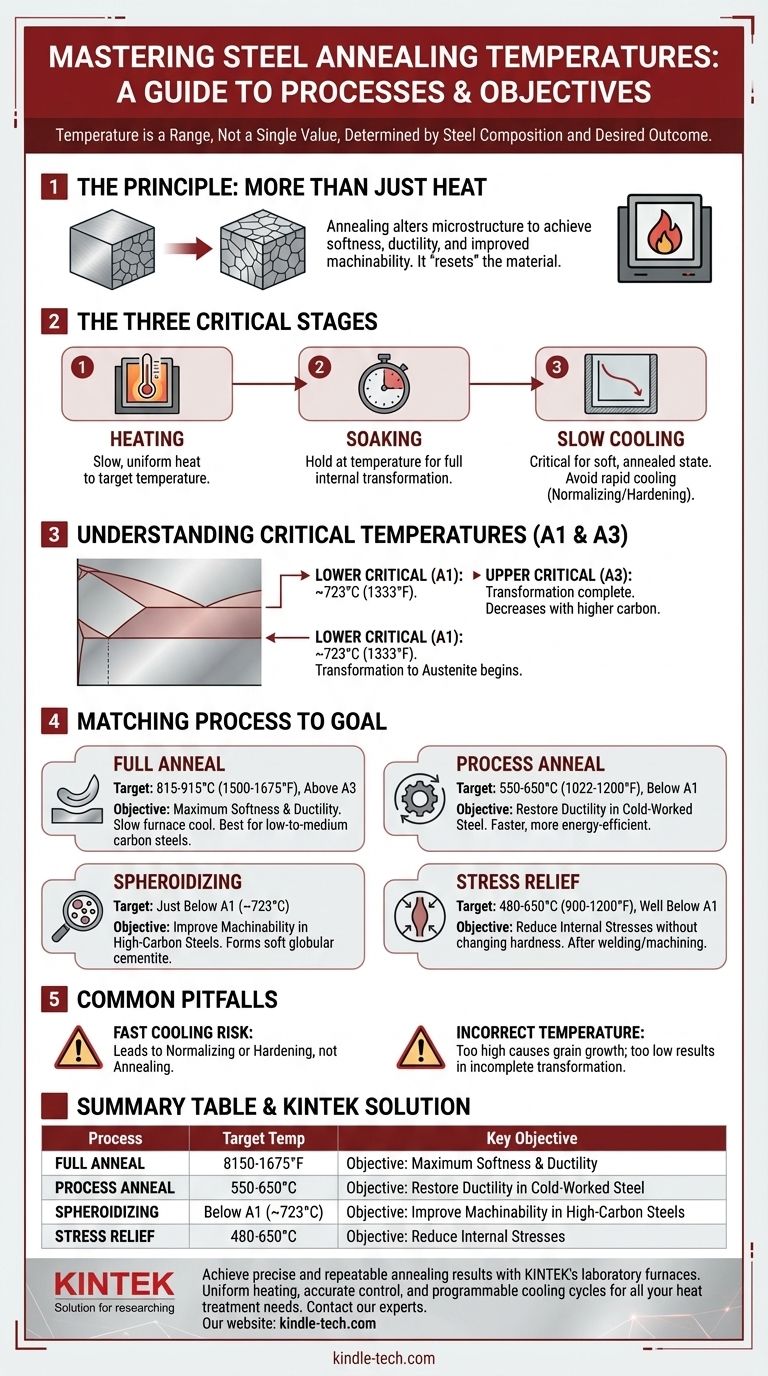

The Principle of Annealing: More Than Just Heat

Annealing is a heat treatment process fundamentally designed to alter a steel's internal microstructure. This change "resets" the material, typically making it softer, more ductile (less brittle), and easier to machine or form.

The Three Critical Stages

Successfully annealing steel requires precise control over three distinct phases:

- Heating: The steel is slowly and uniformly heated to a specific target temperature.

- Soaking: The steel is held at this temperature for a set duration, allowing the internal structure to fully transform.

- Cooling: The steel is cooled at a very slow, controlled rate. This stage is arguably the most critical for achieving a soft, annealed state.

The Role of Critical Temperatures

The target temperature for annealing is directly related to the steel's critical temperatures, which are points where its crystal structure changes.

The most important of these is the lower critical temperature (A1), around 723°C (1333°F), where the structure begins to transform into a phase called austenite. The upper critical temperature (A3) is where this transformation is complete, and its exact value decreases as carbon content increases.

Matching the Process to the Steel and Goal

Different objectives require different types of annealing, each with its own temperature range.

Full Annealing (For Maximum Softness)

A full anneal creates the softest, most ductile state possible. The steel is heated approximately 30-50°C (50-90°F) above the A3 critical temperature, soaked, and then cooled very slowly in an insulated furnace.

This process ensures the entire grain structure is refined and reformed into a coarse pearlite structure, which is very soft and machinable.

Process Annealing (For Cold-Worked Parts)

Also known as sub-critical annealing, this process is used to restore ductility in low-carbon steels that have been hardened by cold working (e.g., stamping or drawing).

The steel is heated to a temperature just below the A1 critical temperature, typically 550–650°C (1022–1200°F). Because it doesn't form austenite, it's faster and more energy-efficient than a full anneal.

Spheroidizing (For High-Carbon Steels)

High-carbon steels contain hard cementite structures that make them difficult to machine. Spheroidizing addresses this by heating the steel to just below the A1 temperature for an extended period.

This process causes the hard cementite to form small, round globules (spheroids) within the softer iron matrix, dramatically improving the steel's machinability.

Stress Relief (To Reduce Internal Stresses)

Welding, heavy machining, or grinding can introduce significant internal stresses into a steel component. A stress relief anneal reduces this stress without significantly changing the steel's core strength or hardness.

This is done by heating the steel to a much lower temperature, well below the A1 line, typically between 480-650°C (900-1200°F), holding it, and then slowly cooling it.

Understanding the Trade-offs and Common Pitfalls

Choosing the wrong process or executing it incorrectly can lead to undesirable results.

The Importance of Slow Cooling

The defining feature of a full anneal is the extremely slow cooling rate. If the steel is cooled too quickly (e.g., in still air or by quenching in water), it will not be softened. Instead, it will form harder, stronger microstructures, a process known as normalizing (air cooling) or hardening (quenching).

Annealing vs. Normalizing

These two processes are often confused. Both heat the steel to a similar temperature, but annealing requires slow furnace cooling while normalizing involves cooling in ambient air.

The result is a key difference: annealing produces soft steel, while normalizing produces a stronger, slightly harder steel with a more refined grain structure.

The Risk of Incorrect Temperatures

Heating the steel too far above the target temperature can cause excessive grain growth, which can make the final product weak or brittle. Conversely, not heating it high enough will result in an incomplete transformation and a failure to achieve the desired properties.

How to Apply This to Your Project

Always consult the data sheet for your specific steel alloy, but use these principles to guide your choice.

- If your primary focus is maximum softness and formability for a low-to-medium carbon steel: A full anneal above the A3 temperature is the correct choice.

- If your primary focus is improving machinability for a high-carbon tool steel: A spheroidizing anneal just below the A1 temperature is required.

- If your primary focus is restoring ductility to a cold-formed part made of low-carbon steel: Use a faster and cheaper process anneal below the A1 temperature.

- If your primary focus is simply reducing internal stress from fabrication without changing hardness: A low-temperature stress relief anneal is the most effective approach.

By matching the heat treatment process to your specific steel and objective, you gain precise control over its final properties.

Summary Table:

| Annealing Process | Target Temperature Range | Key Objective |

|---|---|---|

| Full Anneal | 815-915°C (1500-1675°F) | Maximum softness & ductility |

| Process Anneal | 550-650°C (1022-1200°F) | Restore ductility in cold-worked steel |

| Spheroidizing | Just below A1 (~723°C) | Improve machinability in high-carbon steel |

| Stress Relief | 480-650°C (900-1200°F) | Reduce internal stresses without changing hardness |

Achieve precise and repeatable annealing results with KINTEK's laboratory furnaces. Our equipment ensures uniform heating, accurate temperature control, and programmable cooling cycles—critical for successful full annealing, spheroidizing, and stress relief processes. Whether you're working with tool steels, low-carbon alloys, or fabricated components, KINTEK provides reliable solutions for all your lab's heat treatment needs. Contact our experts today to discuss the perfect furnace for your specific steel annealing applications.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a vacuum drying oven utilized for AlCrFeNiTix powders? Prevent Oxidation & Preserve High-Entropy Alloy Purity

- Is a furnace endothermic or exothermic? Uncover the Science of Home Heating

- How does a vacuum sintering furnace facilitate MgO densification? Optimize Purity and Density with KINTEK Solutions

- What is the difference between vacuum cast and vacuum form? Choose the Right Process for Your Prototype

- What industry is brazing used? Critical Joining Process for Aerospace, Medical & Automotive

- What are the disadvantages of heat treatment furnace? Uncover the Hidden Costs & Complexities

- What is sintering of powder metals? Transform Powder into High-Performance Metal Parts

- What is the function of the EAF? Powering a Sustainable, Agile Future for Steel Production