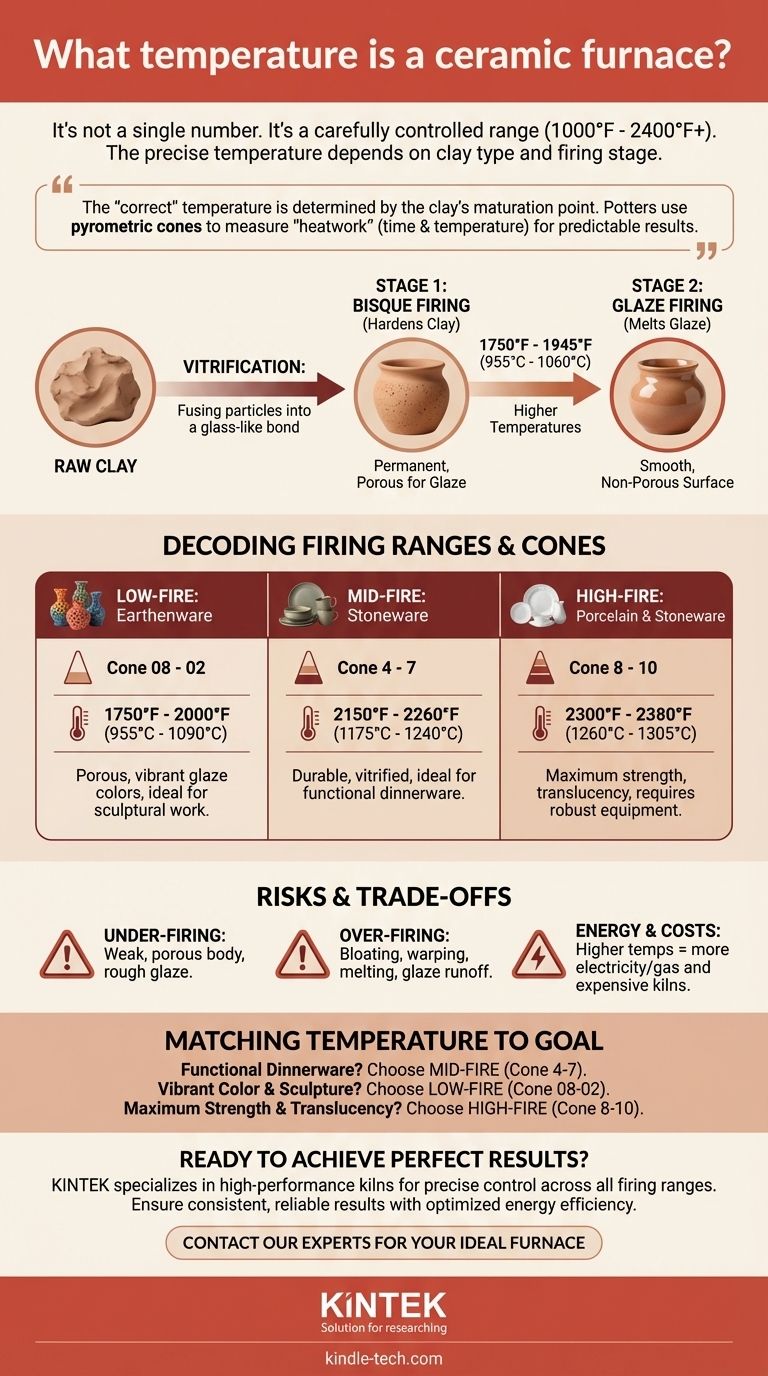

The temperature of a ceramic furnace isn't a single number, but rather a carefully controlled range that can span from approximately 1000°F (538°C) to over 2400°F (1315°C). The precise temperature is dictated entirely by the type of clay being used and the specific stage of the ceramic process, whether it's an initial bisque firing or a final glaze firing.

The central takeaway is that the "correct" temperature is not a fixed value but is determined by the maturation point of a specific clay body and its corresponding glaze. Potters measure this using a system of pyrometric cones, which account for both time and temperature to achieve predictable results.

Why Temperature is the Critical Variable

To truly understand ceramic furnace temperatures, you must first understand the transformative process that turns soft clay into a hard, permanent object. Temperature is the catalyst for this chemical and physical change.

The Transformation from Clay to Ceramic

The primary goal of firing is to heat the clay until its particles begin to fuse together in a process called vitrification. This process melts the silica and other elements within the clay, forming a glass-like bond between particles.

Proper vitrification is what gives a ceramic piece its strength, durability, and, depending on the clay, its inability to absorb water.

Two Primary Firing Stages

The ceramic process typically involves two separate firings, each with a distinct purpose and temperature range.

The first is the bisque firing, a lower-temperature firing (typically between 1750°F and 1945°F / 955°C and 1060°C). This initial firing hardens the clay, making it permanent and porous enough to easily absorb a glaze.

The second is the glaze firing, which is usually done at a higher temperature. This firing melts the applied glaze, causing it to fuse with the clay body and create the final smooth, often glossy, and non-porous surface.

Decoding the Firing Ranges

Ceramics are categorized into temperature ranges, often referred to as low-fire, mid-fire, and high-fire. Each range is suitable for different types of clay and produces different results.

The Cone System: A Better Measure Than Temperature

Professionals rarely rely on temperature alone. Instead, they use pyrometric cones—small, specially formulated ceramic pyramids that bend at a specific combination of time and temperature (known as "heatwork").

Cones provide a much more accurate measure of a firing's progress than a simple thermometer. Firing ranges are designated by cone numbers, such as "Cone 06" (low-fire) or "Cone 6" (mid-fire).

Low-Fire: Earthenware (Cone 08 to 02)

This range covers temperatures from roughly 1750°F to 2000°F (955°C to 1090°C). Earthenware clays fired in this range remain slightly porous after firing and are known for accommodating bright, vibrant glaze colors that can burn out at higher temperatures.

Mid-Fire: Stoneware (Cone 4 to 7)

Operating between approximately 2150°F and 2260°F (1175°C to 1240°C), this is the most common range for studio potters and small-scale production. It provides an excellent balance, creating durable, vitrified stoneware that is ideal for functional pottery like dinnerware.

High-Fire: Porcelain & Stoneware (Cone 8 to 10)

This range reaches temperatures from 2300°F to 2380°F (1260°C to 1305°C). It is used to fire porcelain and some very durable stonewares. High-firing creates the strongest and most vitrified pieces, and it is essential for achieving the classic translucency of porcelain.

Understanding the Trade-offs

Selecting a firing temperature is a decision with direct consequences for your final product, your costs, and your equipment.

The Risk of Under-firing

Firing a piece below its recommended maturation temperature results in a weak, porous body. Glazes will not melt properly, leading to a dry, rough surface that is not food-safe and will easily scratch or flake off.

The Danger of Over-firing

Firing a piece too high is equally destructive. The clay body can bloat, warp, or even melt into a puddle on the kiln shelf. Glazes can become overly fluid, running off the pot and potentially damaging your equipment.

Energy and Equipment Costs

Higher temperatures require significantly more electricity or gas, increasing the cost of every firing. Furthermore, kilns capable of consistently reaching high-fire temperatures (Cone 8+) are more expensive and require more robust components than those designed for low-fire work.

Matching the Temperature to Your Goal

Your choice of firing temperature should be a direct reflection of your project's requirements.

- If your primary focus is creating durable, functional dinnerware: Mid-range stoneware (Cone 4-7) offers the best balance of strength, water resistance, and energy efficiency.

- If your primary focus is vibrant color and sculptural work: Low-fire earthenware (Cone 08-02) is ideal as it preserves the brilliance of many glazes that are unstable at higher temperatures.

- If your primary focus is achieving maximum strength and translucency: High-fire porcelain (Cone 8-10) is the standard, though it requires a kiln capable of reaching these demanding temperatures.

Ultimately, mastering temperature control is the key to transforming raw clay into enduring ceramic art.

Summary Table:

| Firing Range | Cone Number | Temperature Range | Common Clay Types | Key Characteristics |

|---|---|---|---|---|

| Low-Fire | Cone 08 to 02 | 1750°F to 2000°F (955°C to 1090°C) | Earthenware | Porous, vibrant glaze colors, ideal for sculptural work |

| Mid-Fire | Cone 4 to 7 | 2150°F to 2260°F (1175°C to 1240°C) | Stoneware | Durable, vitrified, ideal for functional dinnerware |

| High-Fire | Cone 8 to 10 | 2300°F to 2380°F (1260°C to 1305°C) | Porcelain, Stoneware | Maximum strength, translucency, requires robust equipment |

Ready to achieve perfect ceramic results? Your choice of furnace is critical to the success of your work. KINTEK specializes in high-performance lab furnaces and kilns designed for precise temperature control across all firing ranges—from durable earthenware to sophisticated porcelain. Whether you're a studio potter, an educational institution, or a production facility, our equipment ensures consistent, reliable results while optimizing energy efficiency.

Let's discuss your specific ceramic needs — contact our experts today to find the ideal furnace for your projects and unlock the full potential of your materials.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the concept of muffle furnace? Achieve Clean, Uniform High-Temperature Processing

- What is a muffle furnace used to estimate? A Key Tool for Precise Ash Determination

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing

- What is a muffle furnace? The Definitive Tool for Contaminant-Free, Precise Heating

- What is the material used in muffle furnace? Discover the Heat-Resistant Layers Inside