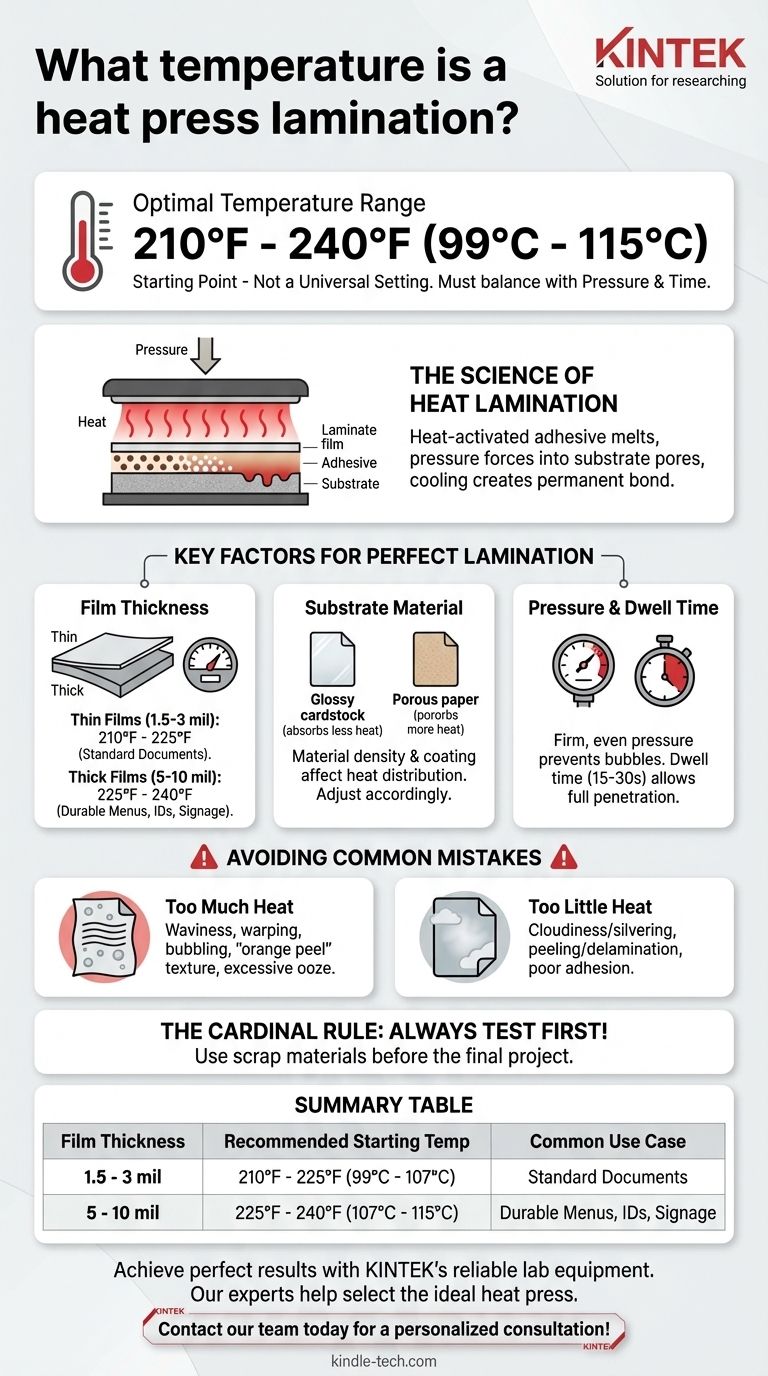

In short, the correct temperature for heat press lamination typically falls between 210°F and 240°F (99°C to 115°C). However, this range is only a starting point, as the ideal temperature is determined by the specific thickness of your laminating film and the material you are laminating.

The single most important takeaway is that temperature is not an isolated setting. It works in a delicate balance with pressure and time. Finding the correct temperature means understanding your specific materials and always performing a test run before committing to your final project.

The Science of Heat Lamination

What Heat Actually Does

Heat lamination, also known as thermal lamination, uses heat-activated adhesive. The laminating film has a layer of solid, cool-to-the-touch polymer adhesive.

When the heat press applies the correct temperature, this adhesive melts into a liquid state. The pressure from the press then forces this molten adhesive into the pores of your substrate (the paper or material being laminated).

As it cools, the adhesive solidifies, creating a permanent, protective, and clarifying bond between the film and the material.

Key Factors That Determine Your Temperature

Achieving a perfect lamination requires balancing three interconnected variables: temperature, pressure, and time. Changing one often requires adjusting the others.

Laminate Film Thickness

This is the most significant factor. Laminating films are measured in mils (one-thousandth of an inch). Thicker films require more heat to melt the larger volume of adhesive.

- Thin Films (1.5 - 3 mil): Require lower temperatures, typically in the 210°F - 225°F range.

- Thick Films (5 - 10 mil): Need higher temperatures to penetrate, often in the 225°F - 240°F range or slightly higher.

The Substrate Material

Different materials absorb and distribute heat differently. A dense, glossy cardstock will heat differently than a porous, uncoated paper.

Always consider your substrate. If you are laminating a heat-sensitive material like certain types of photo paper or synthetic fabrics, you must use the lowest possible temperature that still achieves a good bond.

The Role of Pressure

Pressure ensures the melted adhesive fully permeates the substrate for a strong, bubble-free bond. Most heat presses used for lamination require firm, even pressure.

If your temperature is slightly too low, sometimes a minor increase in pressure or time can compensate. However, excessive pressure can cause the adhesive to squeeze out the sides, a phenomenon known as "ooze."

Dwell Time

Dwell time is the duration that heat and pressure are applied. Thicker films and denser substrates require a longer dwell time to allow the heat to fully penetrate and activate the adhesive. This is often in the range of 15 to 30 seconds but varies by machine and material.

Understanding the Pitfalls and Common Mistakes

Getting the settings wrong can ruin your project. Learning to recognize the signs of incorrect temperature is critical for making adjustments.

Signs of Too Much Heat

Excessive heat is the most common mistake. It melts not just the adhesive but the polyester film itself, leading to several telltale signs:

- Waviness or Warping: The substrate and film will curl or look wavy.

- Bubbling: Small air pockets appear, indicating the adhesive or film has boiled.

- "Orange Peel" Texture: The surface of the laminate looks bumpy and uneven instead of perfectly smooth.

- Excessive Ooze: A significant amount of melted adhesive squeezes out from the edges.

Signs of Too Little Heat

Insufficient heat prevents the adhesive from melting properly, resulting in a weak or incomplete bond.

- Cloudiness or "Silvering": The laminated item looks hazy or has silvery, cloudy patches. This is a clear sign the adhesive did not fully melt and bond.

- Peeling or Delamination: The film can be easily peeled away from the substrate, especially at the corners.

- Poor Adhesion: The bond feels weak and insecure, and the item lacks the desired rigidity.

The Cardinal Rule: Always Test First

Never laminate your final, irreplaceable piece without first testing your settings. Use a scrap piece of the exact same substrate and a small piece of the lamination film. This small step will save you from costly and frustrating errors.

How to Apply This to Your Project

Use these guidelines as a starting point, and adjust based on the results of your test run.

- If your primary focus is standard documents (3 mil film): Start your press at 220°F (104°C) with firm pressure for 20 seconds. If you see cloudiness, increase the temperature by 5 degrees.

- If your primary focus is durable menus or IDs (5 mil film): Begin at 230°F (110°C) with firm pressure for 25-30 seconds. This thickness needs more heat and time to fully bond.

- If your primary focus is rigid signage (10 mil film): Set your initial temperature to 240°F (115°C) with firm pressure for at least 30 seconds. Check for complete clarity and a rigid final product.

- If you are laminating heat-sensitive materials: Use the lowest possible temperature setting, around 210°F (99°C), and compensate with slightly longer dwell time. Prioritize protecting your original over a perfect bond on the first try.

Ultimately, mastering lamination is a process of testing and refinement to find the perfect settings for your specific combination of machine, film, and material.

Summary Table:

| Film Thickness (mils) | Recommended Starting Temperature | Common Use Case |

|---|---|---|

| 1.5 - 3 mil | 210°F - 225°F (99°C - 107°C) | Standard Documents |

| 5 - 10 mil | 225°F - 240°F (107°C - 115°C) | Durable Menus, IDs, Signage |

Achieve a perfect, bubble-free lamination every time. The right equipment is key to mastering temperature, pressure, and time. KINTEK specializes in reliable lab equipment and consumables, serving all your laboratory and professional lamination needs. Let our experts help you select the ideal heat press for flawless results. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the temperature range for compression molding? Optimize Your Process for Perfect Parts

- What are the different types of press machines? Choose the Right Heating Tech for Your Application

- How is conventional heating different from induction heating? Direct vs. Indirect Heat Explained

- Why is it necessary to use high-precision temperature-controlled heating furnaces? Secure Natural Fiber Integrity.

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating